Direct current component control method and system used for three-phase or single-phase inverter

A three-phase inverter, single-phase inverter technology, applied in the direction of converting AC power input to DC power output, output power conversion devices, electrical components, etc., can solve problems such as the defect that the DC component of the output voltage cannot be eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

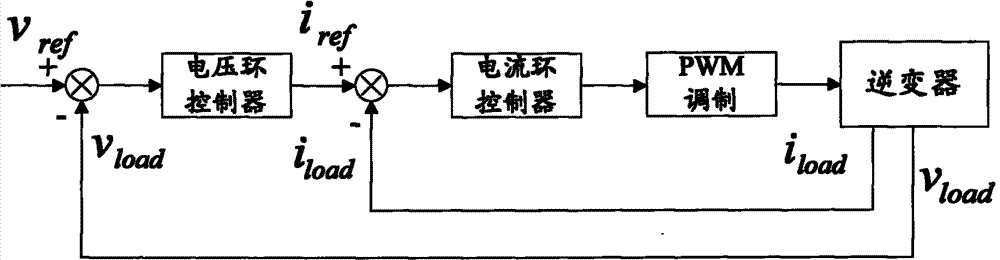

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

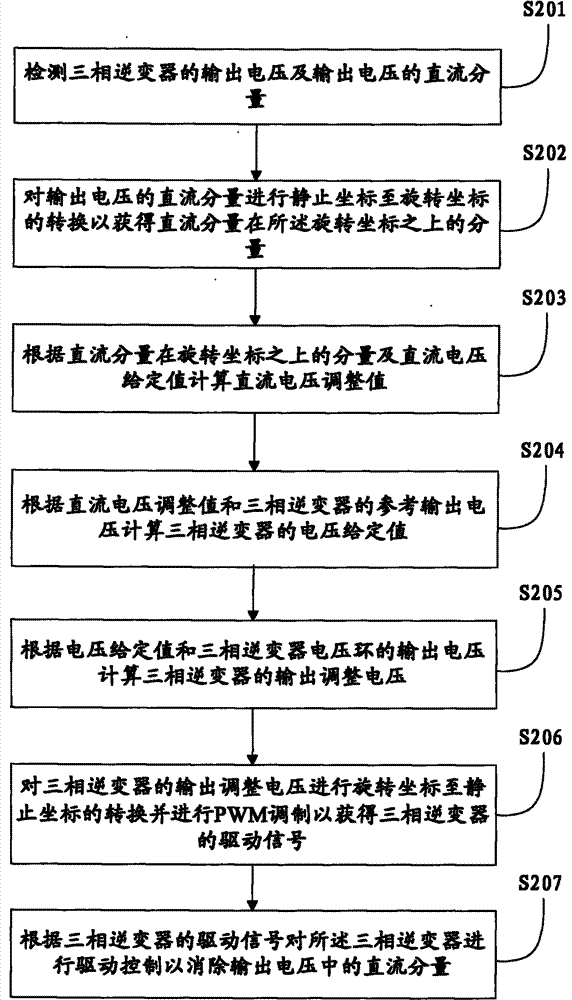

[0024] like figure 2As shown, it is a flow chart of a DC component control method for a three-phase inverter in Embodiment 1 of the present invention, including the following steps:

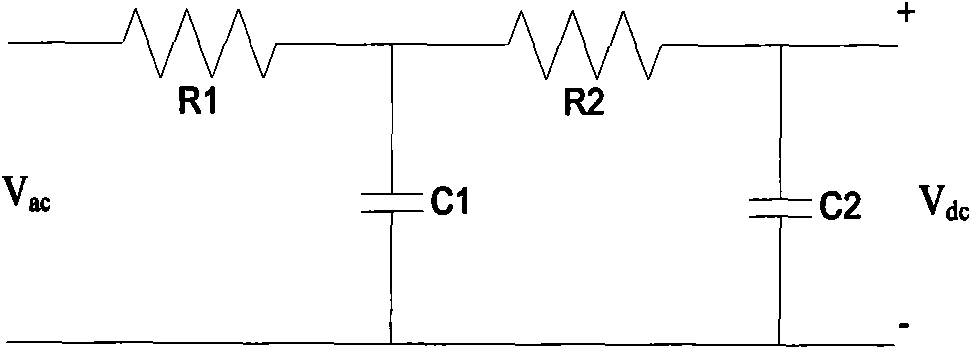

[0025] Step S201, detecting the output voltage of the three-phase inverter and the DC component of the output voltage. Let the detected output voltages of the three-phase inverter be Ua, Ub, and Uc, and the output voltages are Ua, Ub, and Uc to obtain the DC components Uade, Ubde, and Ucdc of the three-phase inverter output voltage through the DC component detection circuit. In one embodiment of the present invention, the DC component of the output voltage of the three-phase inverter is detected by a second-order low-pass filter with a cutoff frequency of about 1 Hz. like image 3 Shown is a schematic diagram of a second-order low-pass filter according to an embodiment of the present invention.

[0026] Step S202, converting the DC components Uadc, Ubdc, and Ucdc of the output voltage from a / ...

Embodiment 2

[0039] like Figure 6 As shown, it is a flowchart of a DC component control method for a single-phase inverter in Embodiment 2 of the present invention, including the following steps:

Embodiment example

[0040] Step S601, constructing the structure of the three-phase inverter according to the structure of the single-phase inverter, and using the single-phase inverter as the first phase of the three-phase inverter. It should be noted that, in the embodiment of the present invention, the single-phase inverter can be used as any phase of the three-phase inverter, which can be A phase, B phase or C phase, so the above-mentioned first phase Can be A phase, B phase or C phase. In the embodiments of the present invention, the single-phase inverter is used as the A-phase as an example for description. Compared with the three-phase inverter, the single-phase inverter lacks the required complete three-phase power supply signal and topology structure, so it is necessary to construct the topology structure of B and C two phases and the corresponding transfer function virtually, so as to meet the requirements of vector control. Requirements for three-phase power supply. As an embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com