Position signal interference processing method in permanent magnet synchronous motor rotor angle measuring device

A permanent magnet synchronous motor, rotor angle technology, applied in the direction of electronic commutator, etc., can solve the problems of motor controller error command, rotor position error error data, etc., to achieve the effect of overcoming errors or errors and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

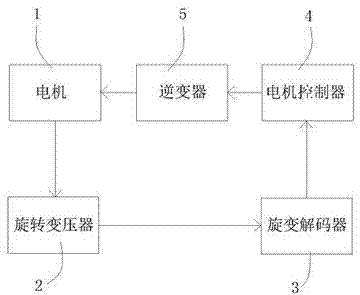

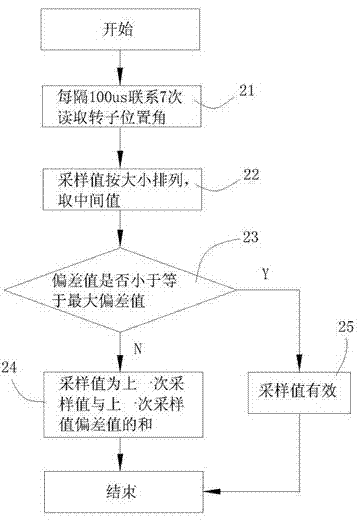

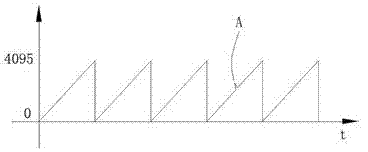

[0020] Such as figure 1 As shown, the motor rotor angle measuring device is composed of a resolver 2, a resolver decoder 3, and a motor controller 4. The resolver 2 is installed on the shaft of the motor 1 and connected to the resolver decoder 3. The resolver decoder 3 is connected to On the motor controller 4, the resolver 4 detects the rotation position of the motor rotor and outputs an analog signal. The resolver decoder 3 is an AU6802N1 decoding chip, and the resolver decoder 3 converts the analog signal into a digital signal, which is resolved by the resolver decoder After the calculation, a 12-bit digital quantity is obtained, which represents the position of the rotor, and the resolver decoder sends the signal to the motor controller. The motor controller 4 analyzes the digital signal to obtain the real-time position and rotational speed of the rotor, and stores the rotor position and rotational speed data,

[0021] The motor controller 4 generates 6 channels of PWM dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com