Powered artificial knee with agonist-antagonist actuation

An artificial and dynamic technology, applied in the field of dynamic artificial knee joints, can solve the problems of not being able to replicate the active working phase of human knee joints, and not being able to generate active mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

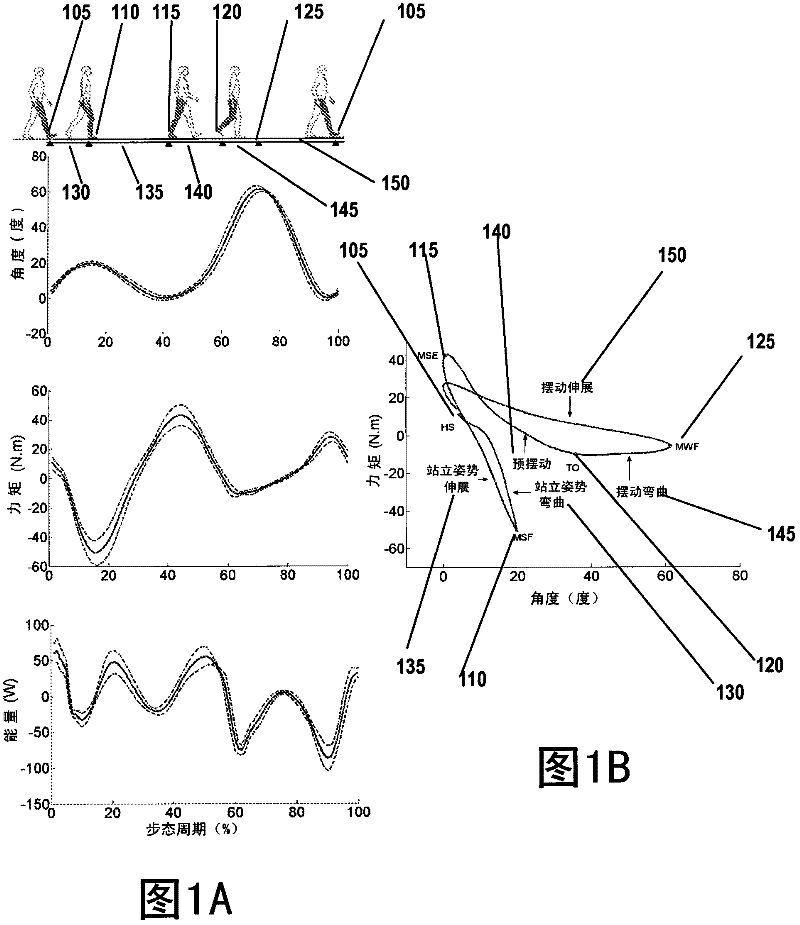

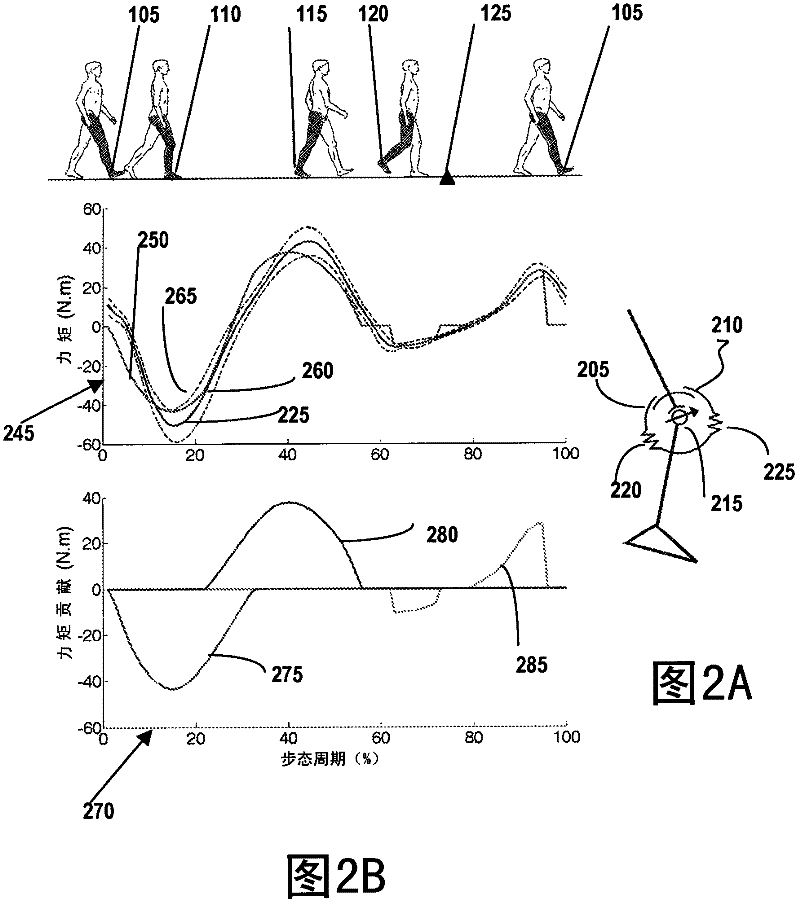

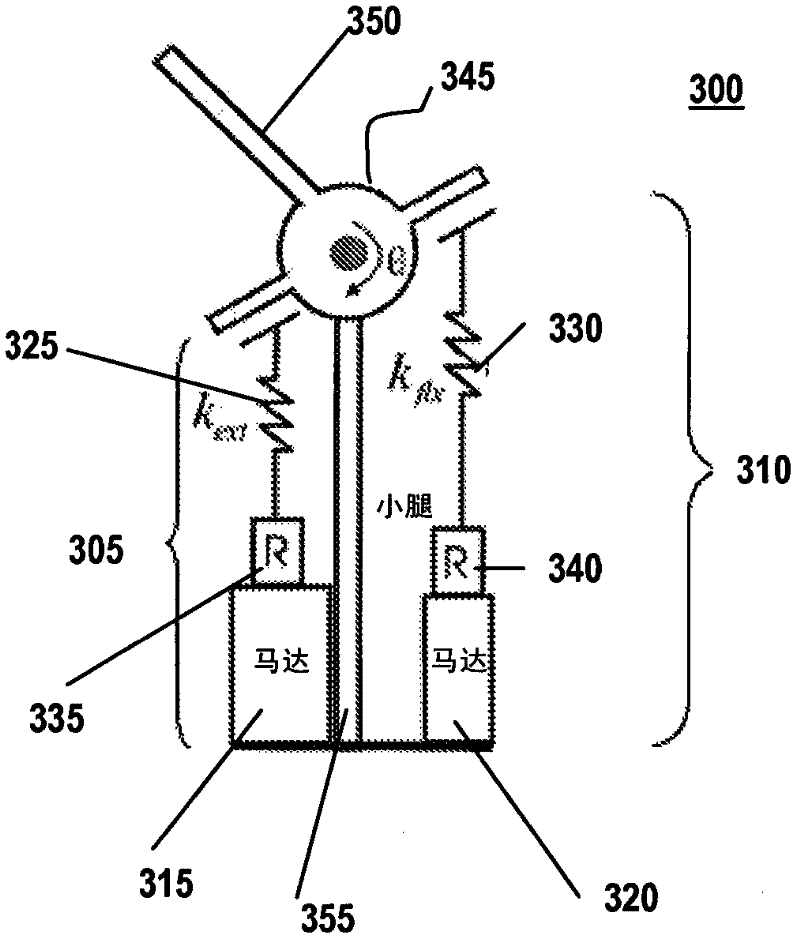

[0035] According to the present invention, a variable damping knee prosthesis has two elastic actuators in series arranged in parallel in a main contractor-antagonist arrangement (arrangement). The prosthetic knee model consists of a variable damper and two elastic clutch units in series across the knee joint. The variable damping control design produces a mechanical structure similar to the human knee when walking on steady-state flat ground. Due to the variable damping properties of the prosthesis, its electrical power requirement during walking is moderate, which allows for an energy-saving dynamic knee. In one application, the variable impedance knee prosthesis according to the invention is advantageously used as part of an untethered (non-restrained) biological robotic leg.

[0036] As used herein, the following terms specifically include, but are not limited to:

[0037] As defined below, "actuator" refers to a type of motor.

[0038] "Primary constrictor" refers to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com