Anchor with separate mixing and discharge heads

A technology of mixing head and bolt, used in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of not containing at the same time, insufficient parts, impossible, etc., to ensure stability and prevent blocking or damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

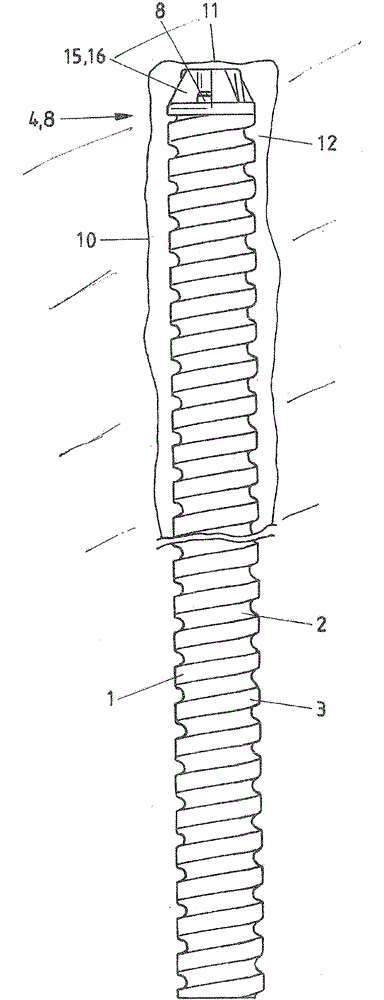

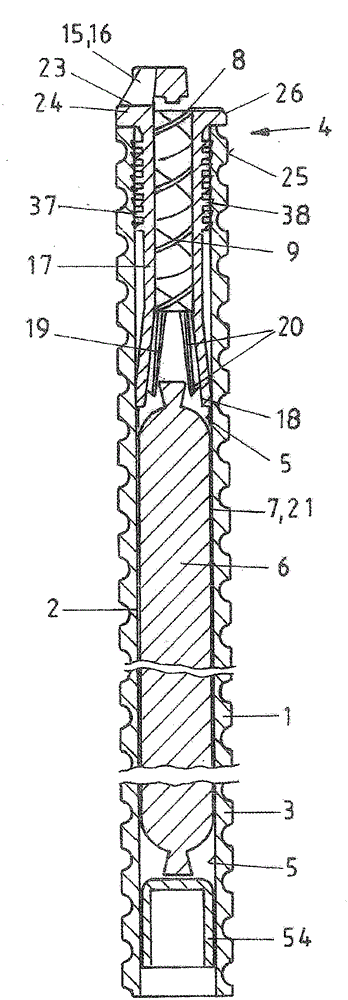

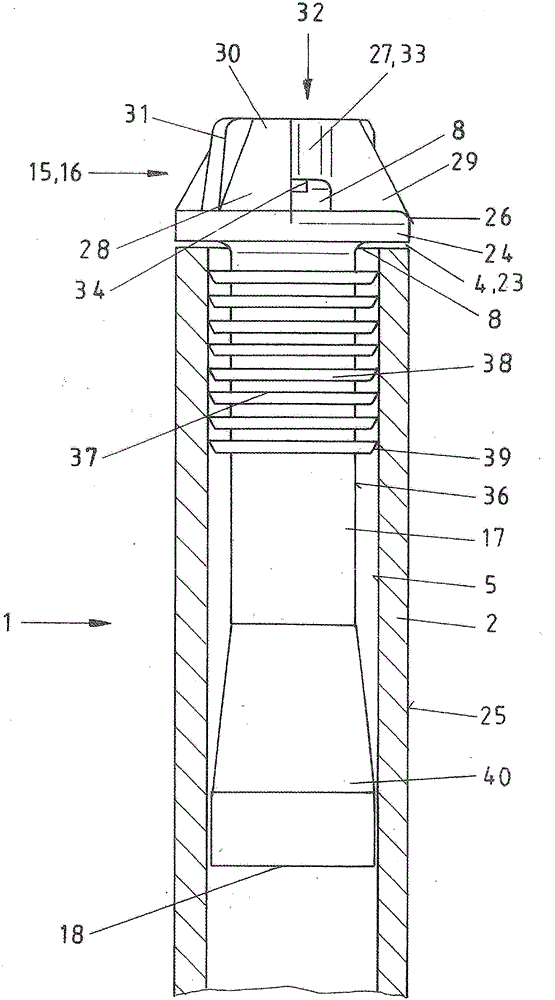

[0047] The bolt tube 2 is hollow with an internal channel 5 and has an inlet (not shown) and an outlet in the form of a discharge end 4 . The bolt tube 2 is fitted on the outside by means of an outer rib 3 . The injection plunger 54 is placed in the inner passage 5 of the bolt tube 2 adjacent to the inlet of the bolt tube 2, so that the anchor box 7 (or the multi-chamber anchor box 21) is arranged between the injection plunger 54 and the mixing head 15. Inside Passage 5. The injection plunger 54 is movable along the inner channel 5 . In use, the jetting plunger 54 may be used to load the anchor cartridge 7 , 21 in the bolt tube 2 .

[0048] The mixing head 15 has an attachment 17 for opening the anchor box, a static mixer 9 , a support plate 24 , a head 16 forming the outlet opening 8 .

[0049] Arranged on the discharge end 4 of the bolted tube 2 is a mixing head 15 with an integral outlet orifice 8 . In fact, this outlet hole 8 is a continuation of the internal channel 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com