A fully automatic kitchen and bathroom waste disposer

A kitchen and bathroom garbage and garbage disposal technology, applied in the direction of grain processing, etc., can solve the problems of reducing the service life of the motor, reducing the service life of the tooth plate or blade, and easy to be blocked, so as to prolong the service life, avoid frontal collision, and discharge quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

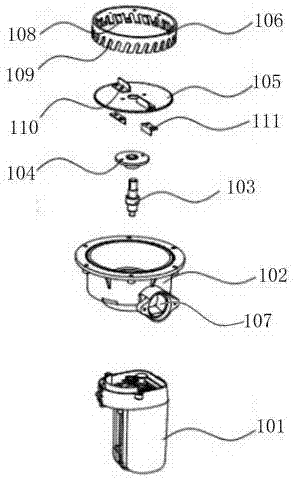

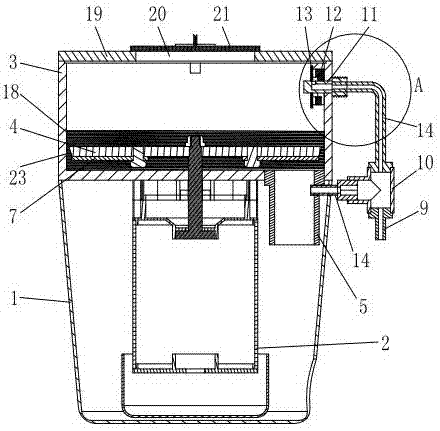

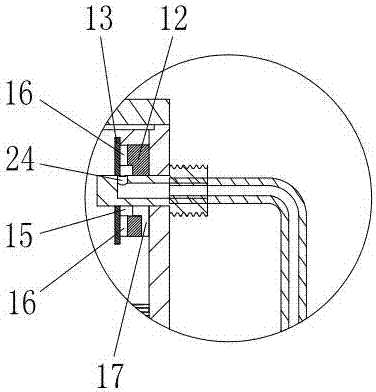

[0031] Such as Figure 2 to Figure 6 As shown, the present invention provides a fully automatic kitchen and bathroom garbage disposer, including a base 1, on which a crushing device is installed, and the crushing device includes a motor 2, a garbage disposal hole 3 and a toothed disc 4, and the toothed The disc 4 is arranged in the garbage disposal hole 3, and a feeding hole is arranged on the bottom surface of the garbage disposal hole 3. The feeding hole is tangent to the inner wall of the garbage disposal hole 3, and a feeding cylinder 5 is matched on the feeding hole; the motor 2 Connect the toothed disc 4 and drive the toothed disc 4 to rotate; the upper and lower surfaces of the toothed disc 4 are respectively provided with a number of upper blades 6 and lower blades 7; the upper blades 6 and lower blades 7 are hinged with the toothed disc 4, and the upper , the blades of the lower blades 6 and 7 are always facing outward with the centrifugal force of the toothed disc 4;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com