Sectional tap

A combination of taps and taps, which is applied in metal processing equipment, tangent devices, manufacturing tools, etc., can solve the problems of tap handle waste, increased enterprise cost, and easy failure, and achieves high tapping accuracy and efficiency, reasonable structure, and durability. good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

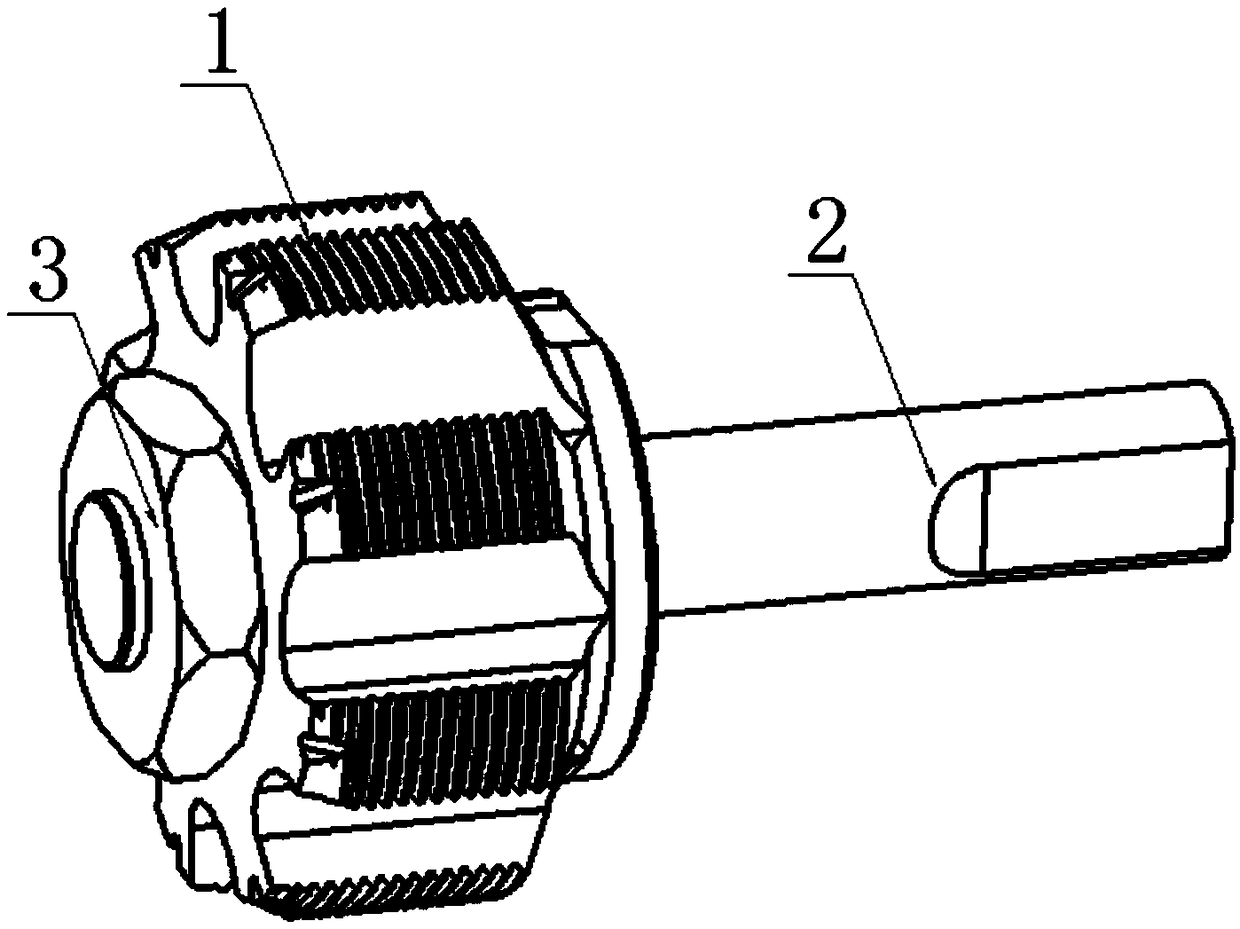

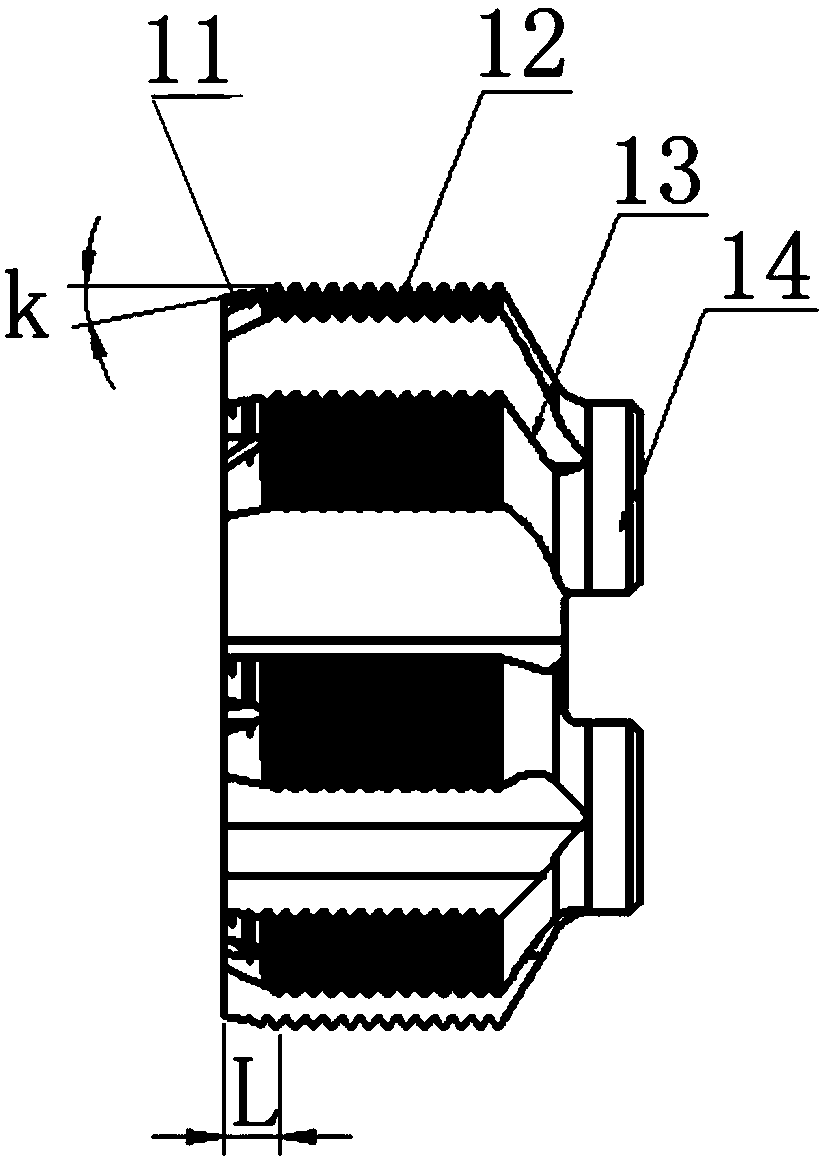

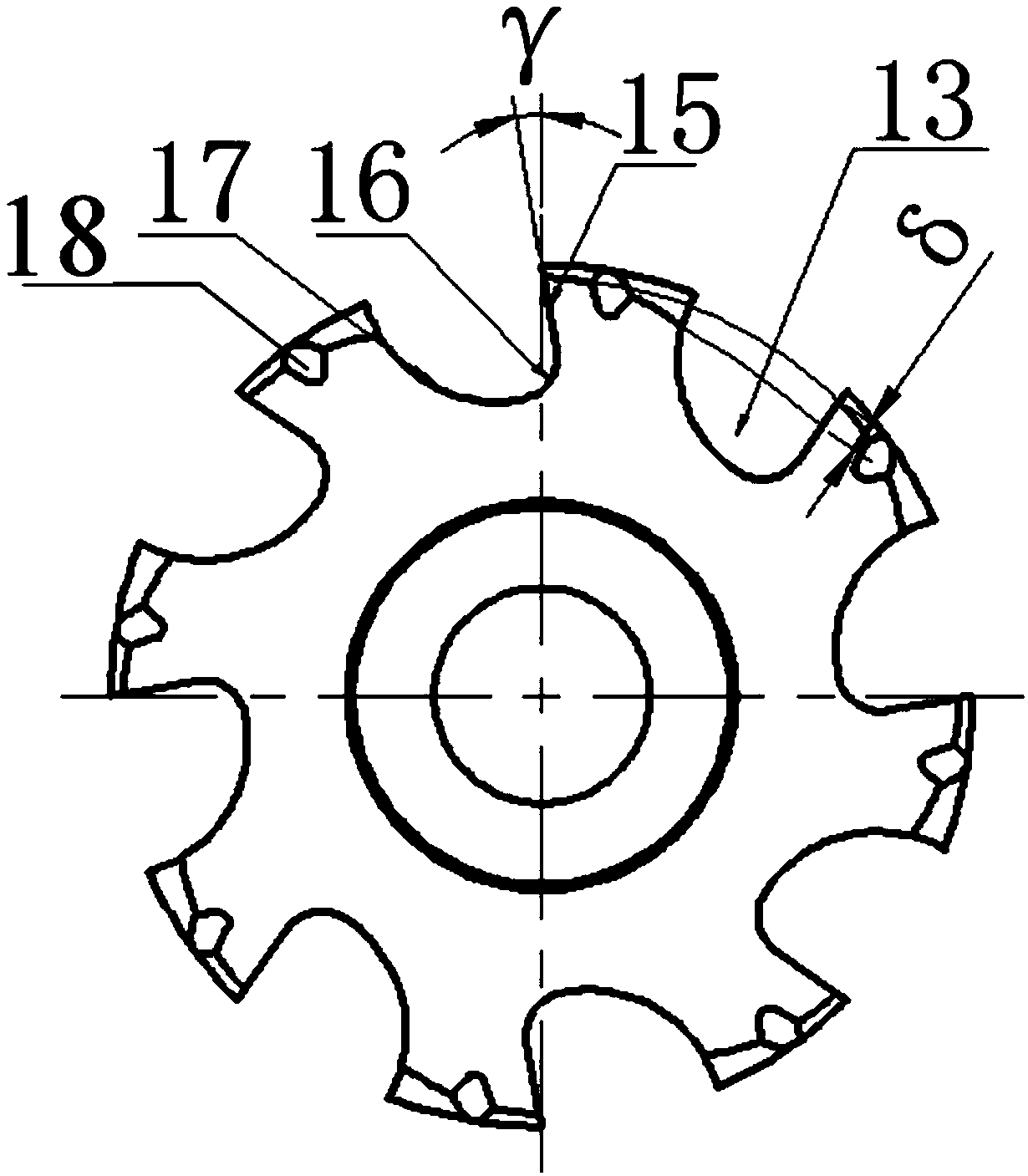

[0027] Such as figure 1 and image 3 As shown, a combination tap of the present invention includes a tap working part 1 , a tap handle 2 and a nut 3 . The tap working part 1 is composed of a cutting part 11 , a calibration part 12 and a chip pocket 13 . The cutting part 11 and the calibration part 12 are distributed with screw teeth, the rake angle γ of the screw teeth is 10°, the relief grinding amount δ of the cutting part is 5.5mm, and the flank face of the cutting part is cut with an oil groove 18, which can increase the Cutting strength and diameter stability, that is, to ensure the cutting strength of the tap, and at the same time the relief angle is not too large, to ensure the centering stability of the combined tap, so as to ensure the dimensional accuracy of the screw hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com