a fiber cutting machine

A fiber cutting machine and cutting section technology, which is applied in the field of spinning, can solve the problems of difficult mixing and sticking, poor quality of blended yarn, and fiber crushing damage, etc., and achieve the effect of increasing the sticking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

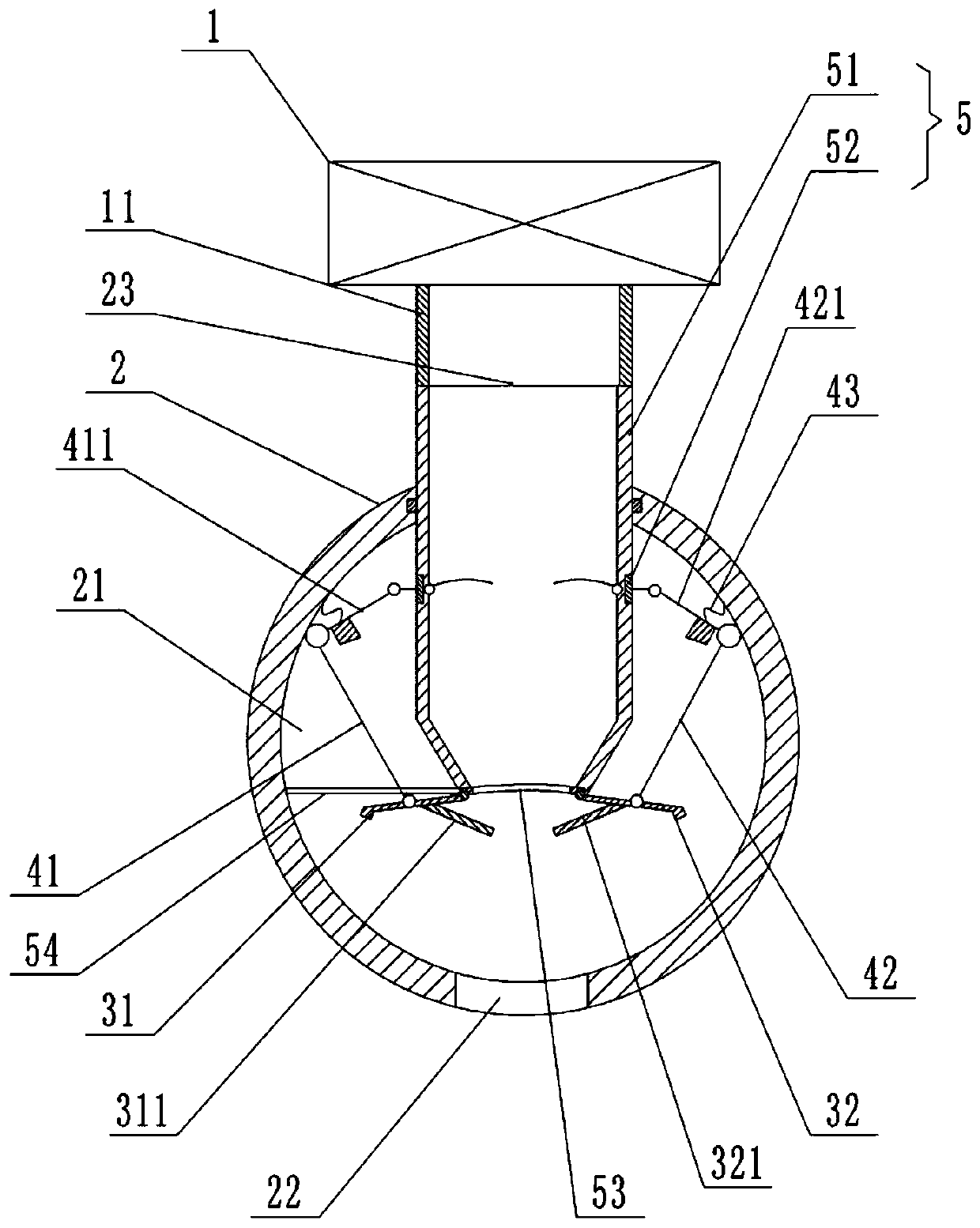

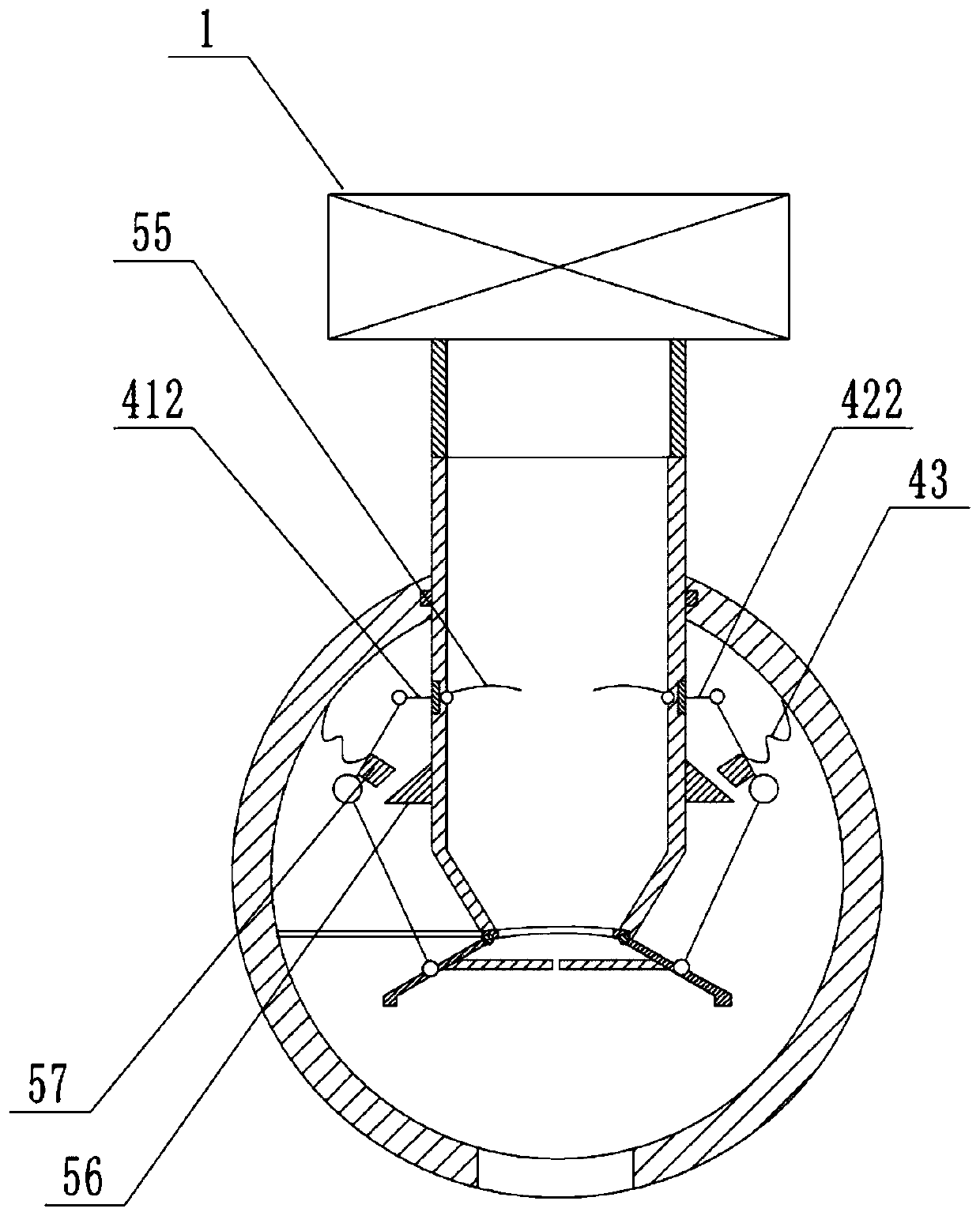

[0023] The reference signs in the drawings of the description include: motor 1, fixed rod 11, cutting part 2, cavity 21, discharge port 22, feed port 23, first cutting cover 31, first cutter 311, second cutting Cover 32, second cutter 321, first pull rod 41, first connecting rod 411, first positioning rod 412, second pulling rod 42, second connecting rod 421, second positioning rod 422, return spring 43, cutting cylinder 5 , cylinder body 51, annular ring 52, rotating ring 53, fixed shaft 54, blade 55, first magnet block 56, second magnet block 57.

[0024] Such as figure 1 and figure 2 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0025] A fiber cutting machine, comprising a motor 1, a cutting part 2, a cutting disc, a power part and a cutting cylinder 5 driven by the motor 1; a spherical cavity 21 is arranged ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com