Obturator valve for a coupling device for pipes

A connection device, obturator technology, applied in the field of obturator valves and devices for connecting pipes, to achieve the effect of enhanced sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

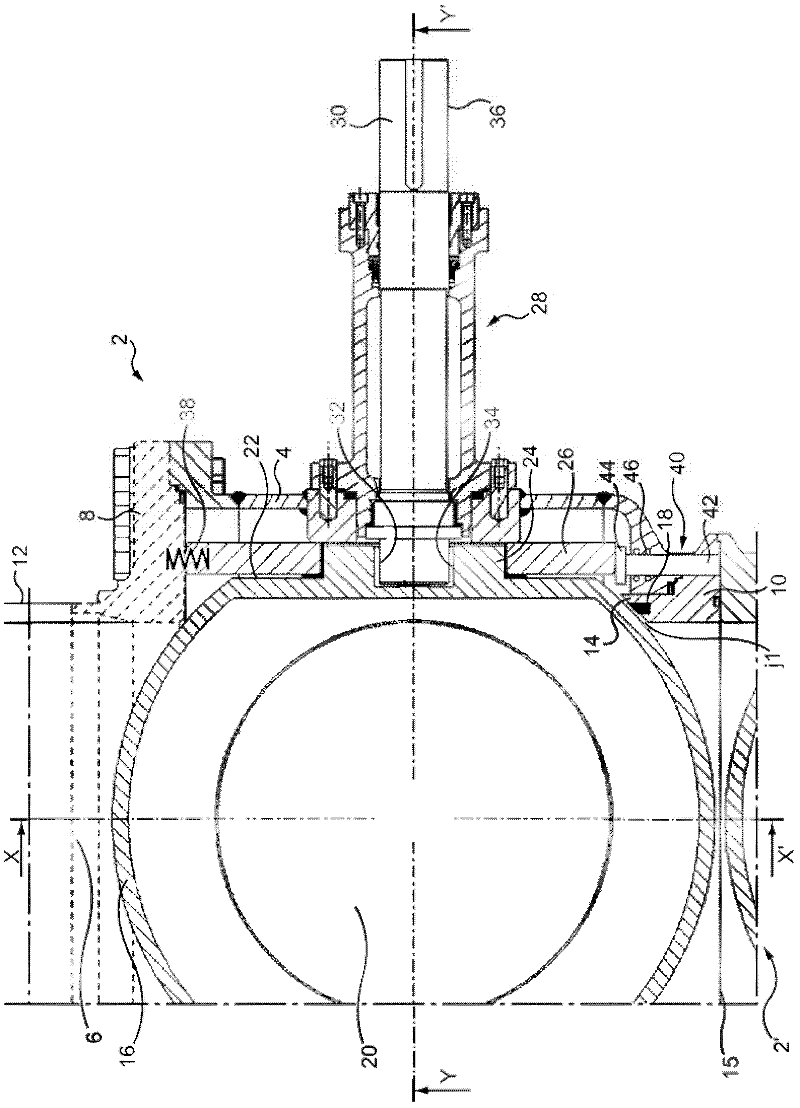

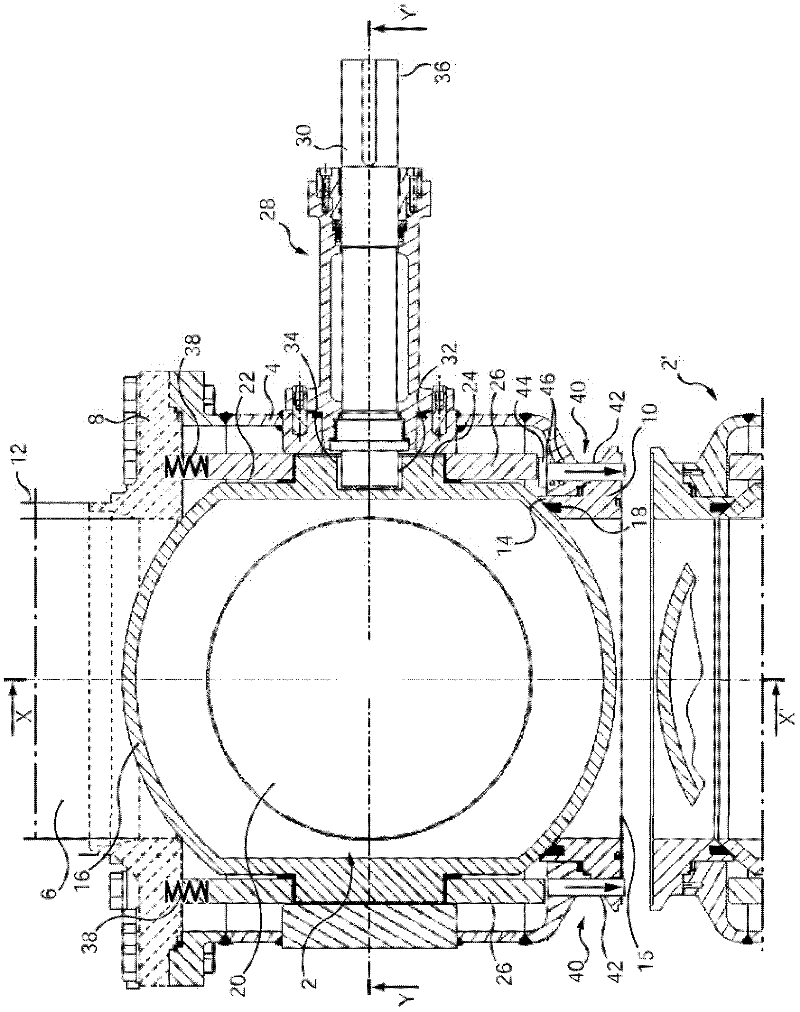

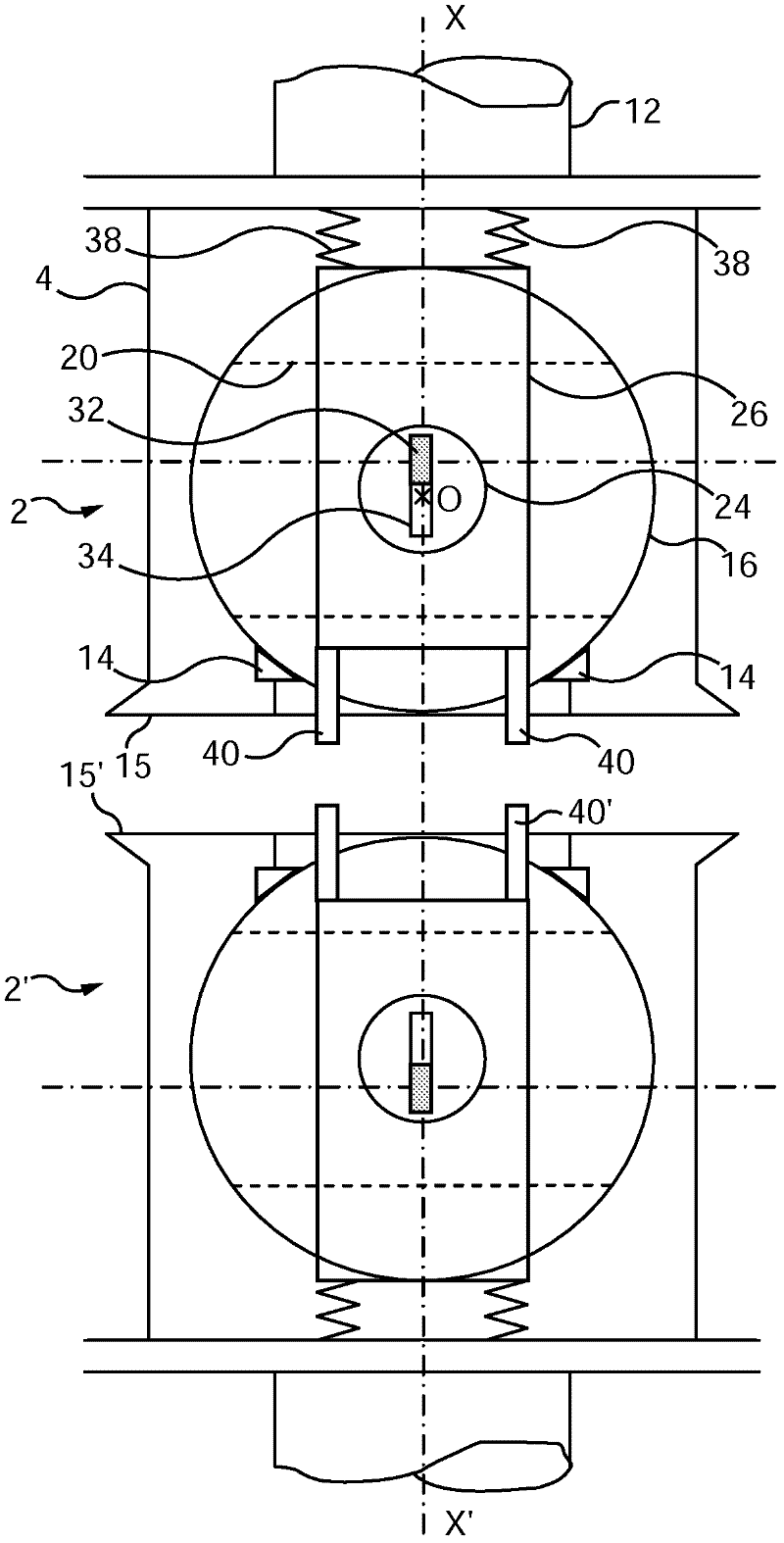

[0039] Figure 1 to Figure 5 The coupling device shown in comprises at least one obturator valve 2 adapted to block and / or allow the passage of fluid from one hydraulic line towards the other hydraulic line.

[0040]The valve 2 is formed by a valve chamber 4, the body of which defines a flow channel 6 extending inside the valve chamber 4 along a first longitudinal axis XX'. According to this first longitudinal axis XX', the valve chamber 4 of the valve 2 has a coupling flange 8 at a first end and a coupling flange 10 at a second end, the flow channel inside the valve chamber 4 6 joins the two flanges 8,10.

[0041] A coupling flange 8 is attached to the valve chamber 4, extends substantially transversely to said valve chamber, and has a coupling end adapted to allow a hydraulic line 12 to be mounted.

[0042] The coupling valve 10 is attached to the valve chamber 4 and forms a valve seat 14 inside the valve chamber. As an example, in the embodiment shown, the valve seat 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com