Automobile cooling system

A technology of cooling system and automobile cooling, applied in liquid cooling, engine cooling, coolant flow control, etc., to achieve the effect of large heat load, low design cost, and ensure normal working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

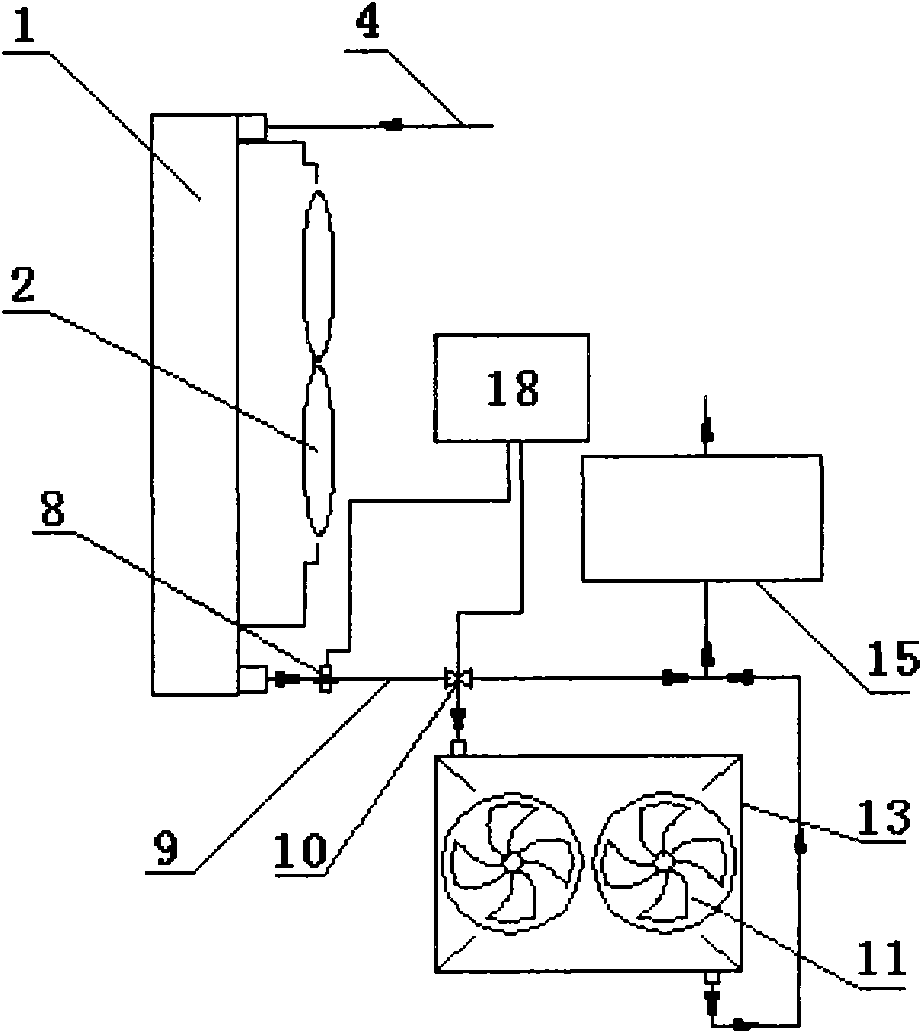

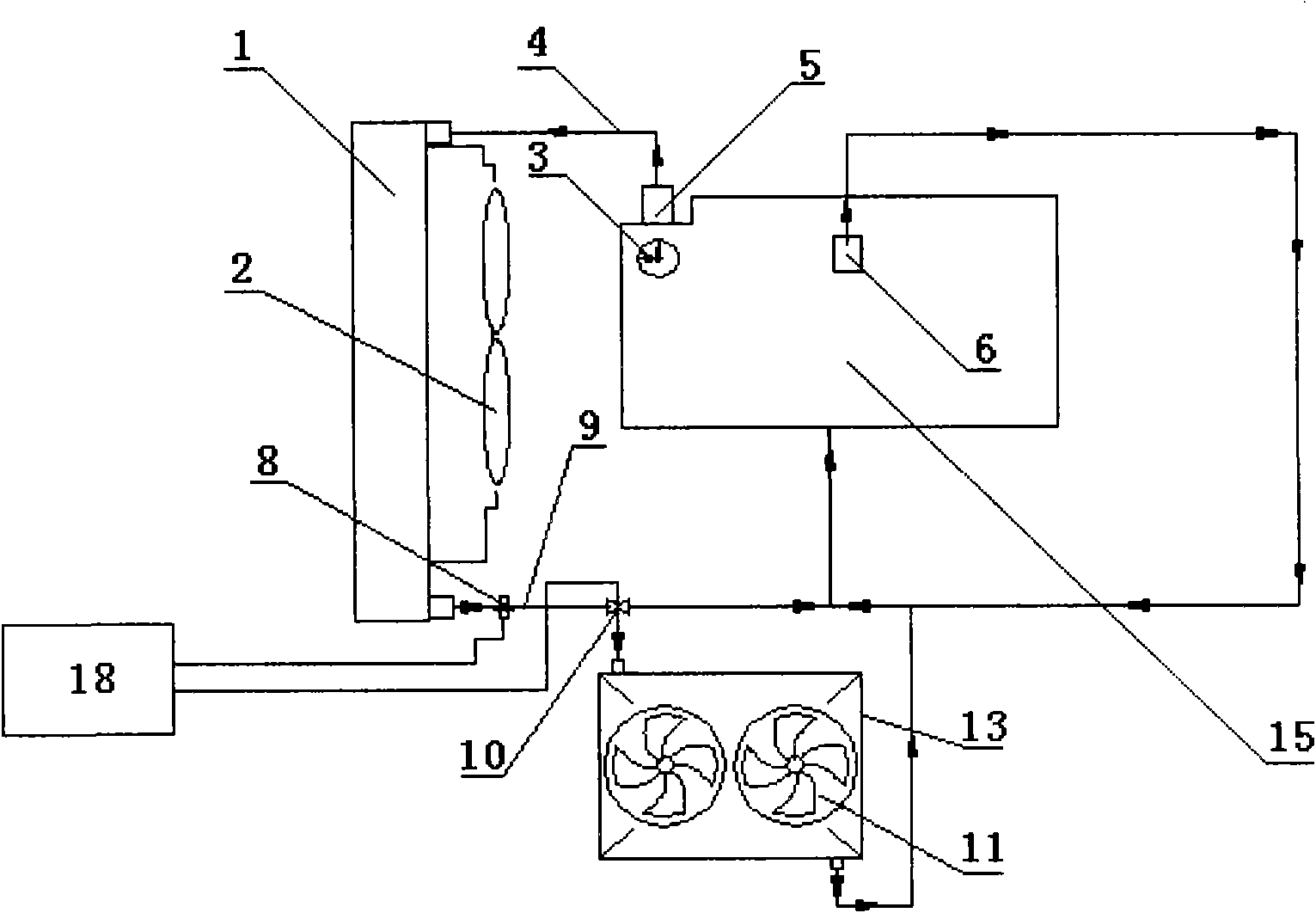

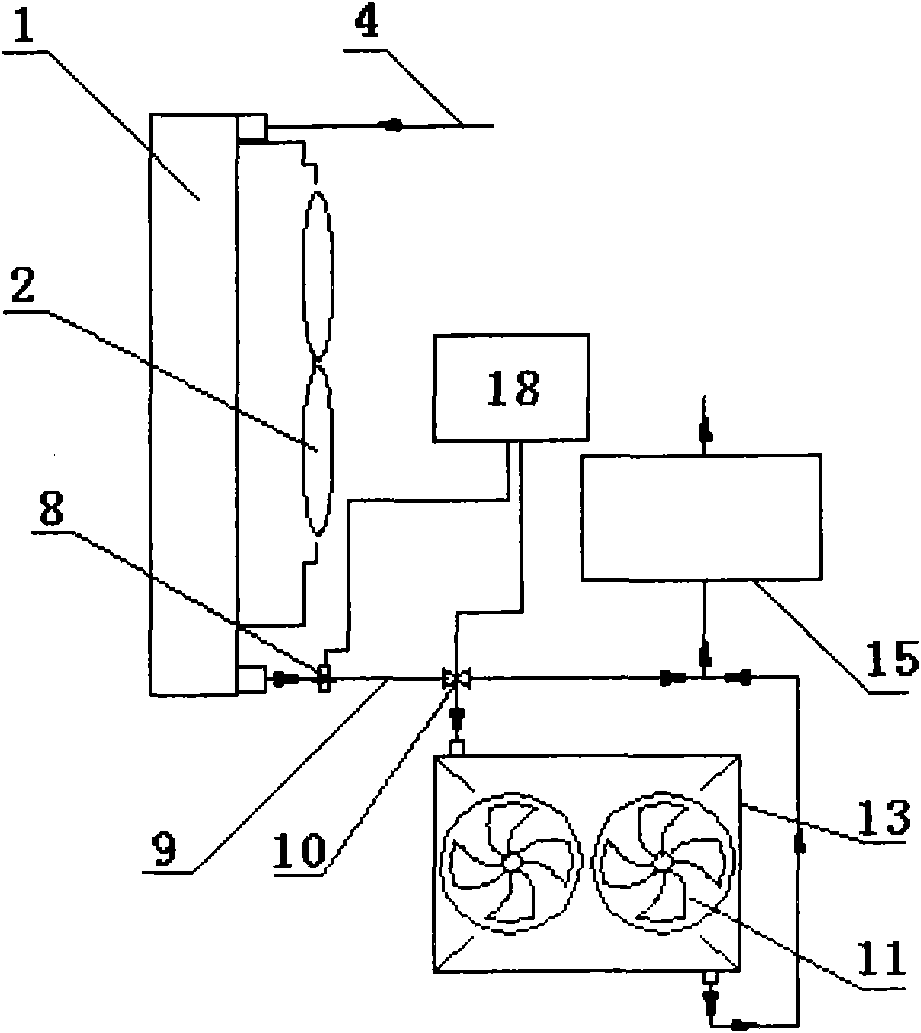

[0009] The automobile cooling system provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] The automobile cooling system is used to remove the excess heat generated by the engine through the circulation of the engine coolant, so as to maintain the engine within the normal operating temperature range and avoid damage. The coolant circulation process of the automobile cooling system is usually divided into a large circulation and a small circulation. The small circulation refers to the circulation of the coolant only in the engine, while the large circulation refers to the circulation of the coolant between the engine and the main radiator. The existing The car cooling system usually controls the conversion of large and small cycles through a thermostat. The temperature regulating device usually includes a temperature sensing component, which opens and closes the flow of the liquid through expansion or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com