Advanced coordinated control system for moisture in cut tobacco dryer

A technology for coordinating control systems and control systems, applied in the direction of tobacco preparation, application, tobacco, etc., can solve problems such as weak oscillation or regulation, difficult to achieve control quality, and complex dynamic relationships, so as to avoid jumping and non-smoothness, eliminate Coupling, the effect of avoiding oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

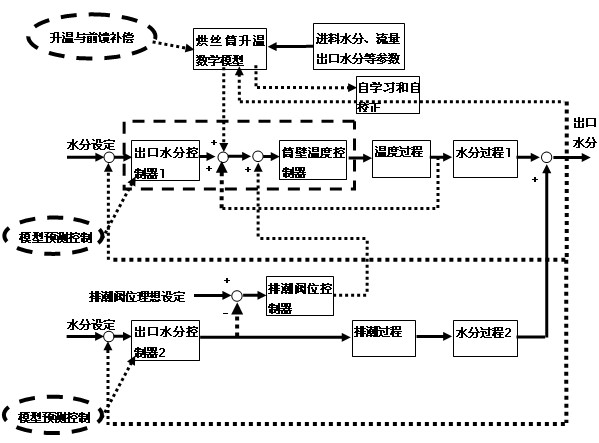

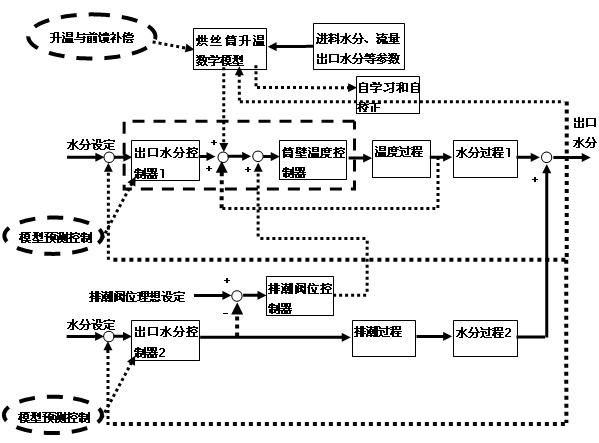

[0025] Such as figure 1 As shown, the present invention provides an advanced coordinated control system for moisture in silk drying machines. The system implements advanced model predictive control for the drying process, and the most important thing is to establish models of the head, middle and tail of the object. These models include: the model of feed flow to outlet moisture, the model of feed moisture to outlet moisture, the model of hot air temperature to outlet moisture, the model of hot air flow to outlet moisture, the model of cylinder wall temperature to outlet moisture, etc. These models are identified using the modern asymptotic identification method (ASYM). The ASYM method is divided into 4 steps:

[0026] (1) Design of test signal. The pseudo-random binary signal is superimposed on the input signal. The amplitude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com