homogeneous substance mixing tank

A uniform mixing and material technology, applied in fluid mixers, mixers, chemical/physical processes, etc., can solve problems such as consuming large energy to overcome frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with schematic diagram, the present invention is described in further detail:

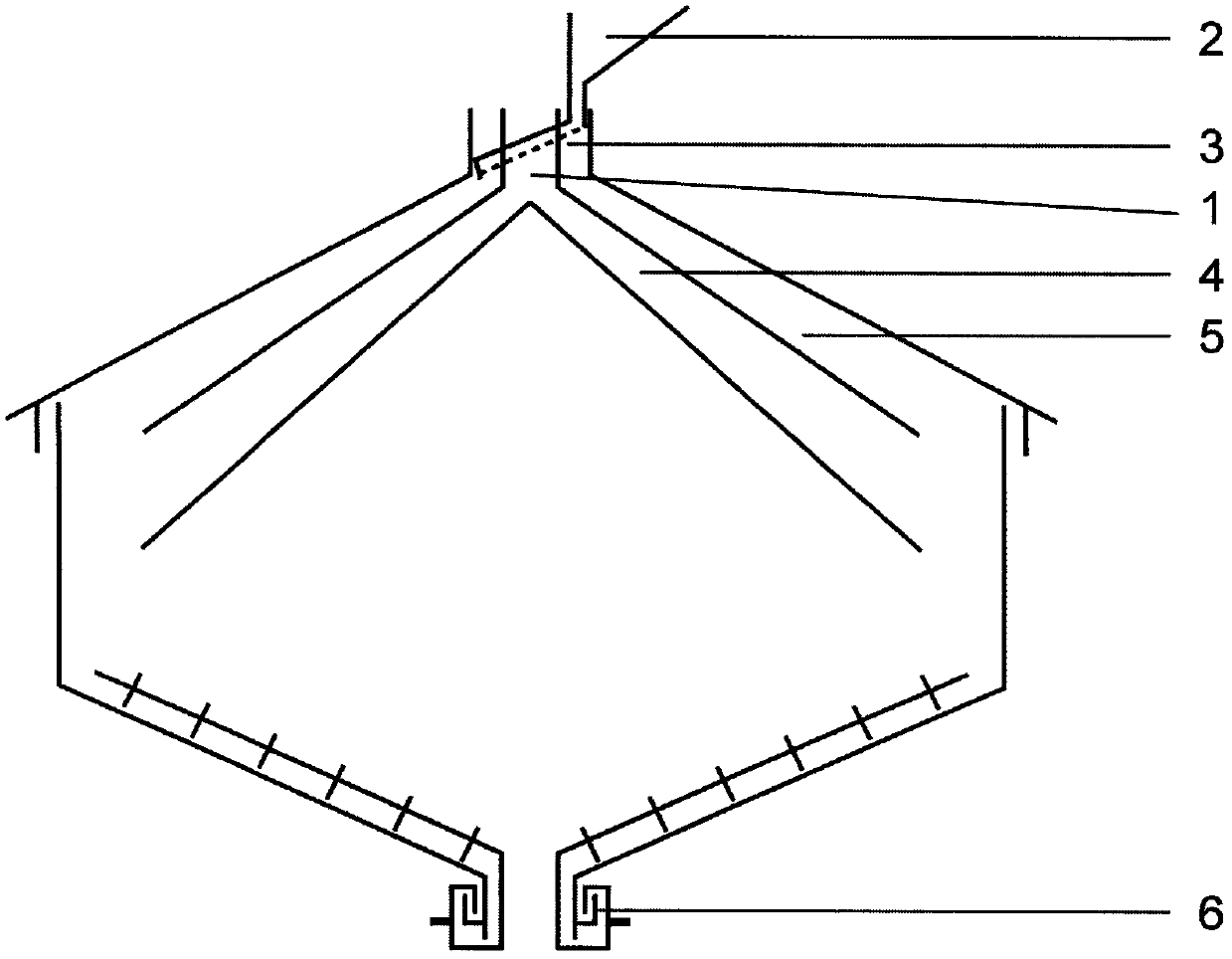

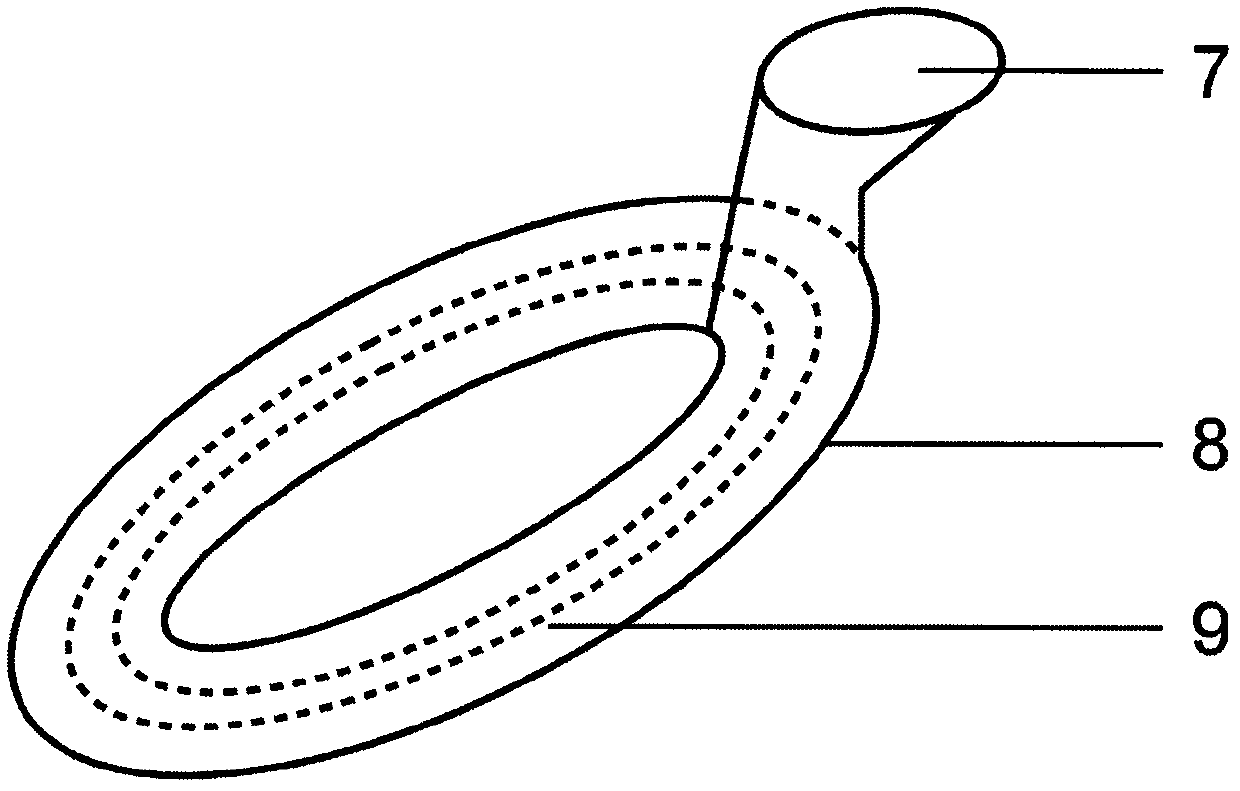

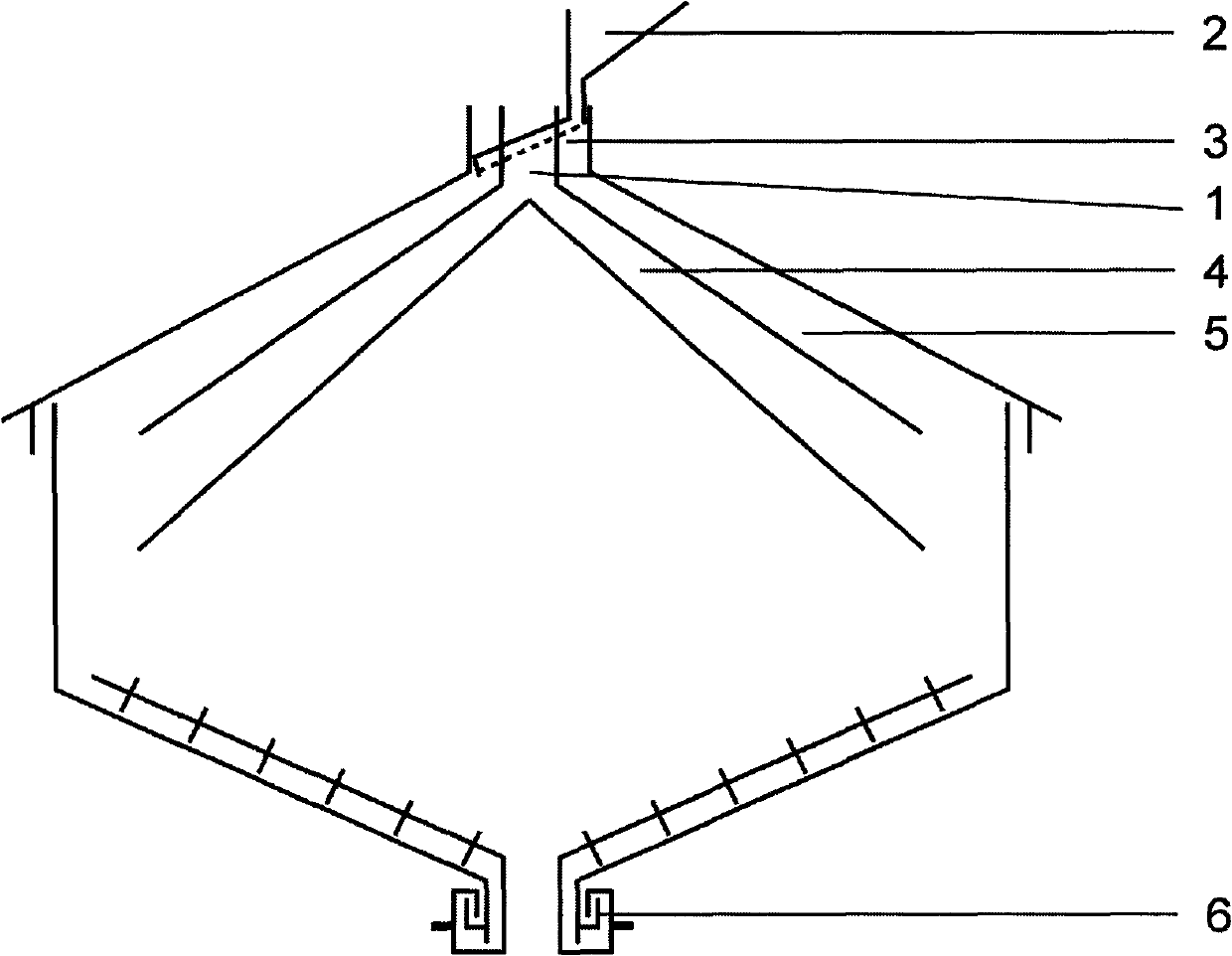

[0039] according to figure 1 , the material A enters from the feed port (1), and along the thinning cone cover (4) of the material A, it is thinned into a cylindrical shape and falls. Material B enters from the feeding port (2) of the inclined feeding pipe ring, along the feeding pipe (8) ( figure 2 ) edge slides from the feed pipe leakage seam (9) material leakage. The leaked material is thinned into a cylindrical shape and falls under the action of the thinning cone cover (5) of the material B.

[0040] Since the two thinning cones are vertically distributed and have the same maximum diameter, the falling cylinder of material B just hits on the falling cylinder of material A.

[0041] Due to the sliding inertia of the material and the difference in the frictional resistance between each layer of the material and the thinning cone, the particles of the material cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com