Support of straightening machine

A straightening machine support and support block technology, applied in the field of straightening machines, can solve the problems of uncertainty in position adjustment accuracy, affecting the quality of steel pipes straightened by the straightening machine, and improving the labor intensity of operators, so as to reduce human factors Intervention, improvement of accuracy and stability, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

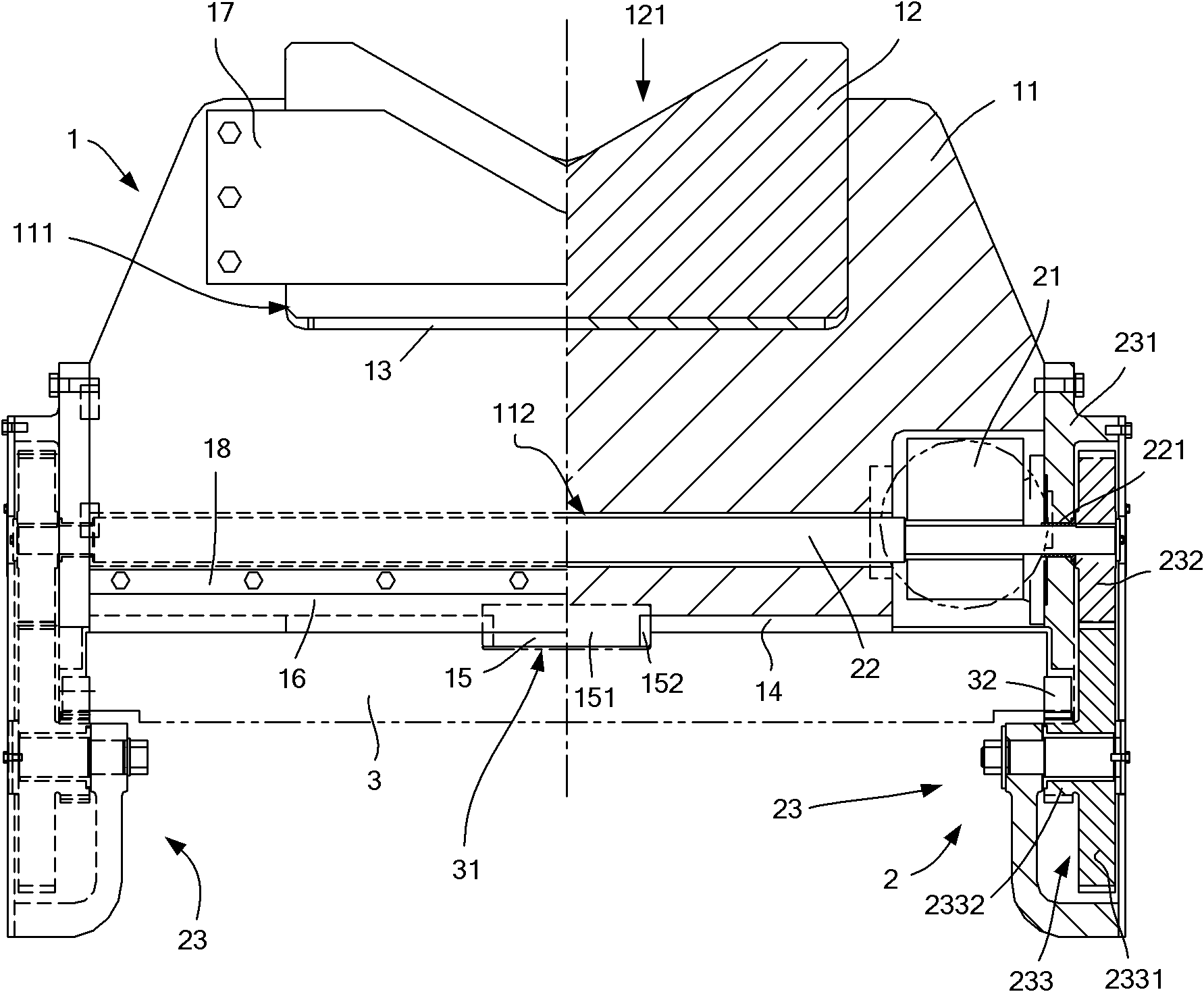

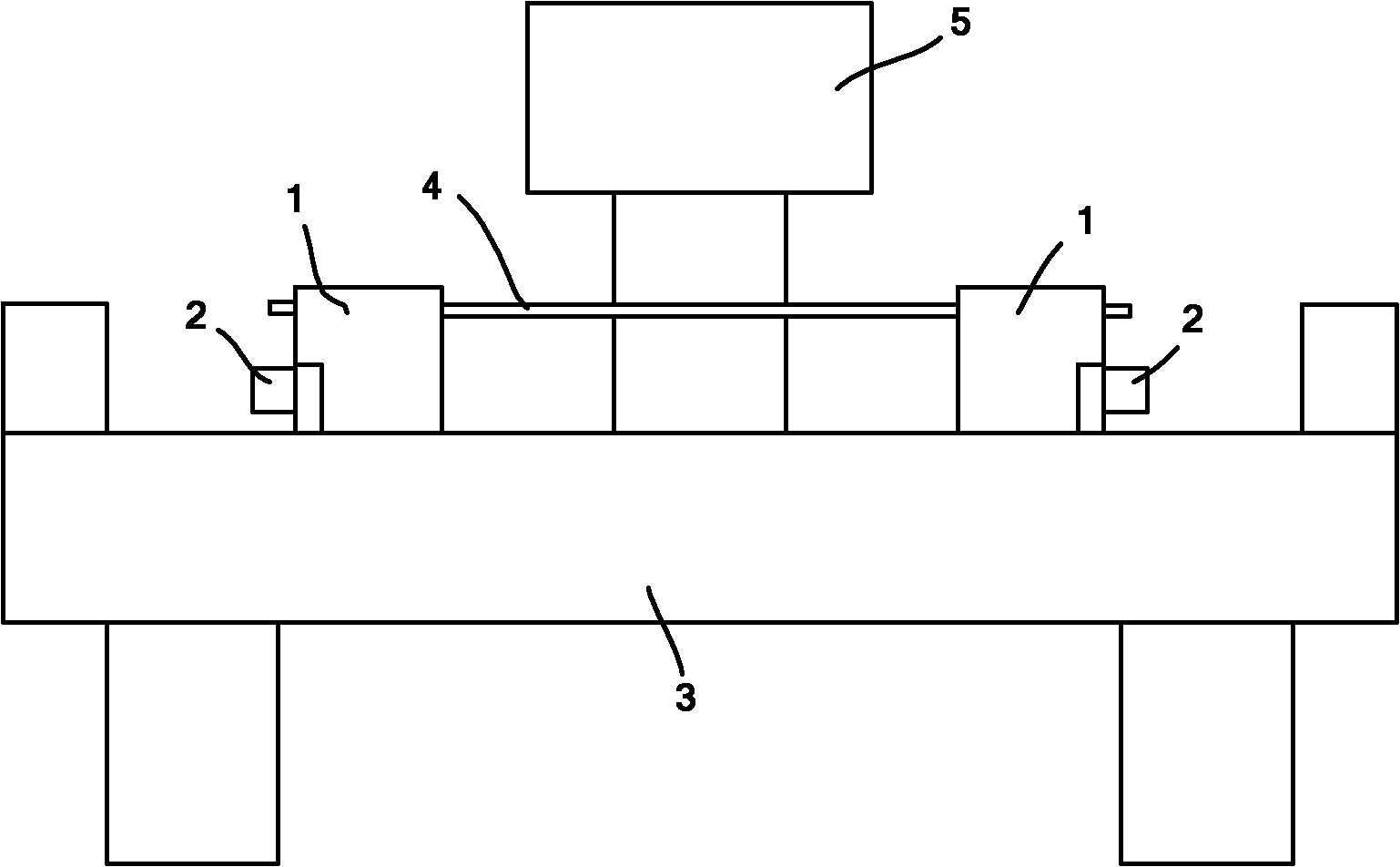

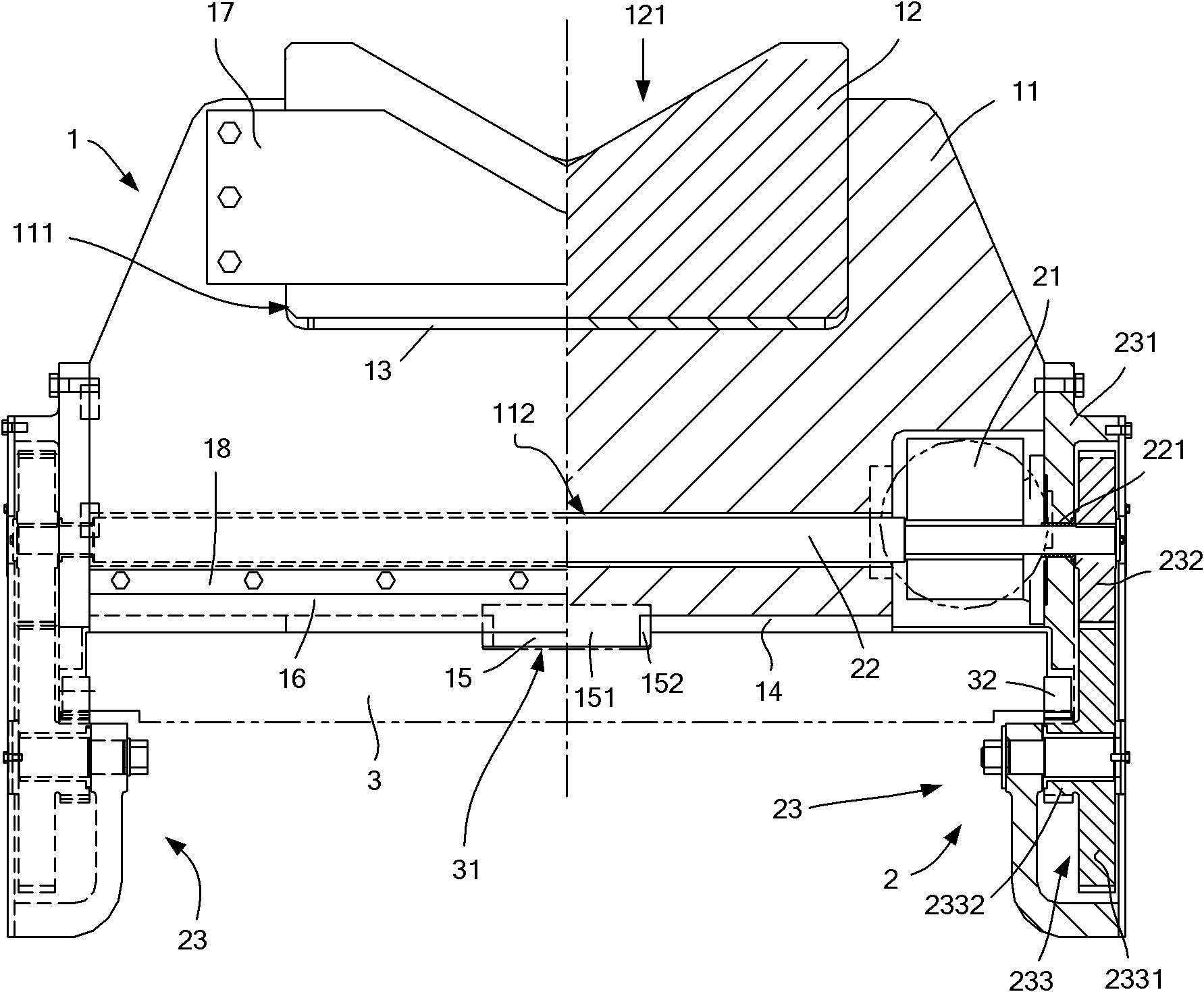

[0019] Such as figure 1 and figure 2 As shown, the present invention includes a supporting device 1 and a transmission mechanism 2, wherein the supporting device 1 is used to be installed on a workbench 3, and supports a steel pipe 4, and cooperates with a pressure head 5 of a straightening machine to straighten the steel pipe 4. The transmission mechanism 2 is used to make the straightener support realize automatic walking on the workbench 3, so that the position positioning of the straightener support of the present invention on the workbench 3 is convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com