Pipe billet whip preventing device and punching machine

An anti-slung and tube blank technology, applied in the direction of perforation tools, feeding devices, storage devices, etc., can solve problems such as hidden safety hazards, damage to buckle tiles, scratches on the outer surface of the capillary tube, etc., and achieve the effect of good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

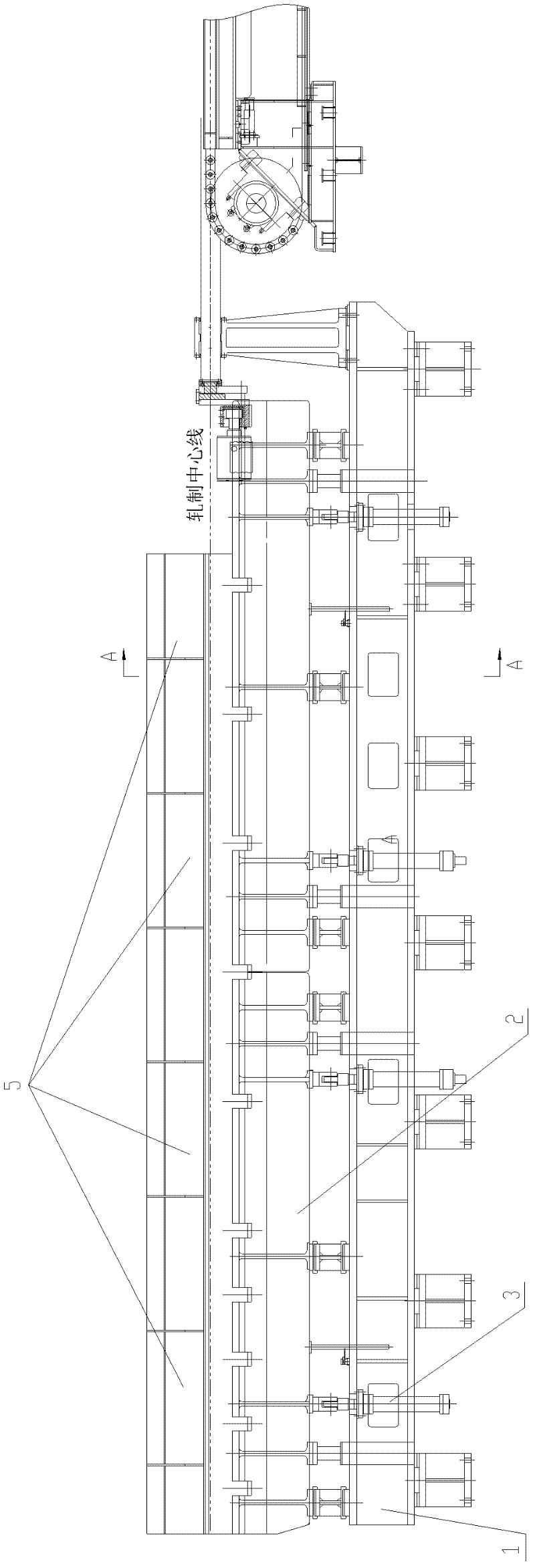

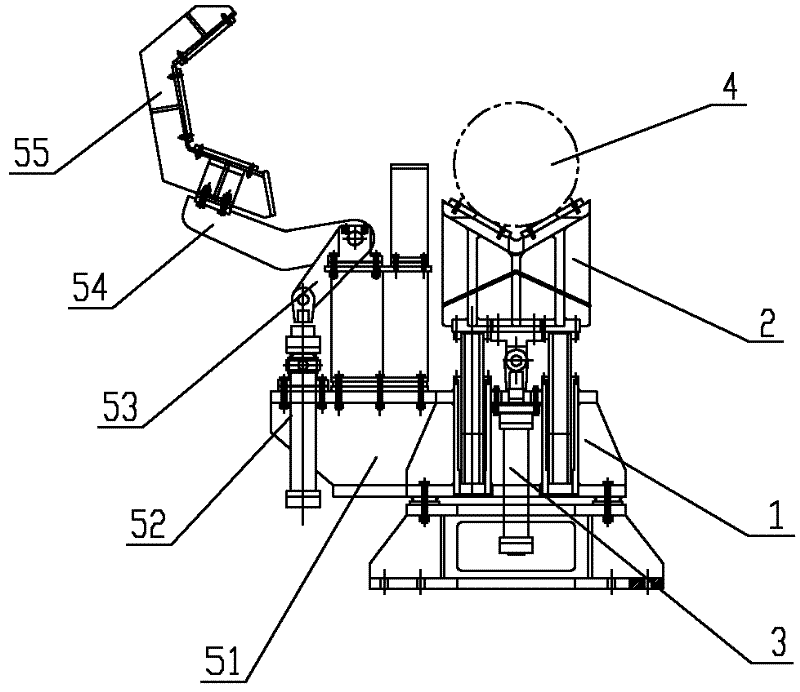

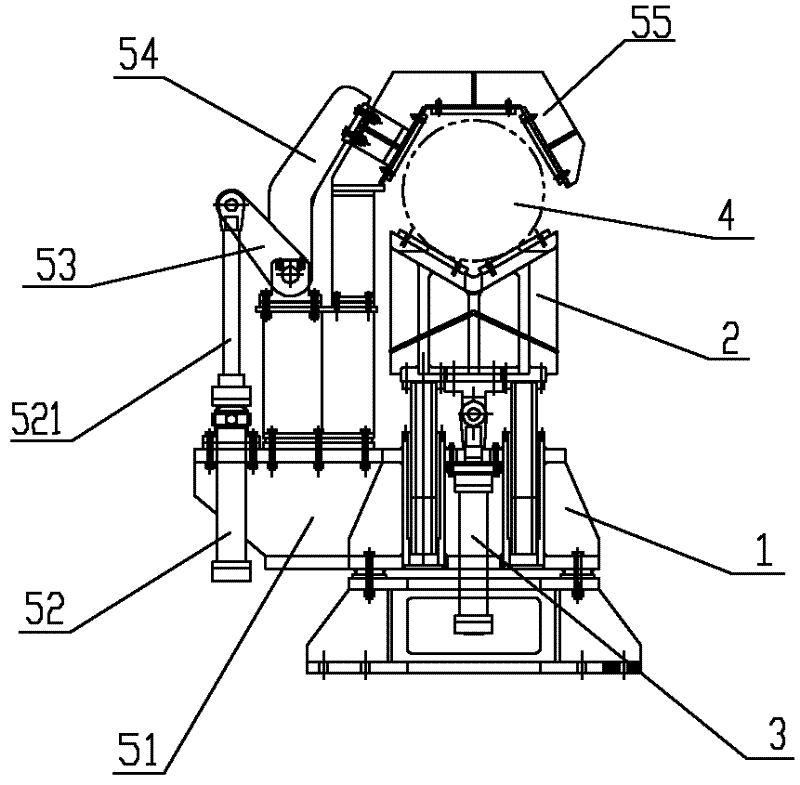

[0023] see Figure 4 , Figure 5 and Figure 6 . The tube blank anti-swing device of the present invention is installed on the inlet platform of the piercing machine. The inlet table of the piercing machine includes a base 1, a tube blank seat 2 installed on the base 1, a tube blank seat lifting hydraulic cylinder 3 is provided between the tube blank seat 2 and the base 1, and a tube blank seat 2 is provided with a Place the V-groove for the tube blank. The anti-swinging device for the tube blank includes: a pair of blocking rod lifting devices 6, blocking rods 7, push-pull devices 8 and connecting blocks 9, which are relatively installed on both sides of the base 1.

[0024] The push-pull device 8 includes two push-pull seats 81 fixedly installed on the ground and a push-pull hydraulic cylinder 82 horizontally installed on the two push-pull seats 81 . If the push-pull seat is relatively large, only one can be used, but preferably two, which can make the push-pull hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com