Round-shape cutting machine for sheet

A technology of circular cutting machine and thin plate, applied in the field of thin plate circular cutting machine, can solve the problems of easy generation of burrs, inaccurate positioning of circular cutting, slow circular cutting speed, etc., and achieve the effect of improving circular cutting speed, smooth edge and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solutions of the present invention are further described below by means of the accompanying drawings and examples.

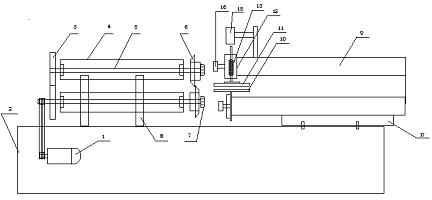

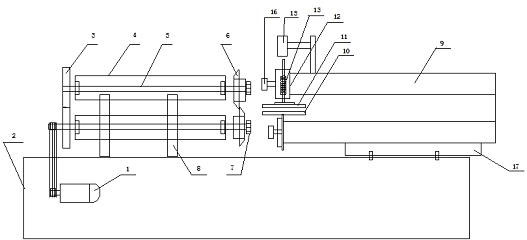

[0010] Such as figure 1 Shown, thin plate circular shearing machine of the present invention, by motor 1, frame 2, transmission gear 3, axle sleeve 4, main shaft 5, scissor blade 6, scissor blade adjustment nut 7, fixed axle sleeve plate 8, circle Disc rack 9, ballpoint pen tray 10, pressure plate 11, spring cover 12, spring 13, finale 14, eccentric pressure wheel 15, set screw 16 and adjustment base plate 17 form.

[0011] The specific connection method is:

[0012] Motor 1 is connected main shaft 5 by belt, and transmission gear 3 and scissors blade 6 are installed on main shaft 5, and main shaft 5 is fixed on the axle sleeve plate 8. The adjustment base plate 17 is connected on the frame 2, the disc frame 9 is fixed on the adjustment base plate 17, the disc is connected on the disc frame 9, the spring cover 12 is fixed on the disc frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com