Control system of integrated circuit tendon-cutting device

A technology of control system and integrated circuit, which is applied in the field of control system, can solve problems such as failure to reflect the situation of integrated circuits in time, damage to the cutting machine, and large mechanical loss of hydraulic devices, so as to prevent a large number of defective products, reduce the number of shutdowns, and improve The effect of cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

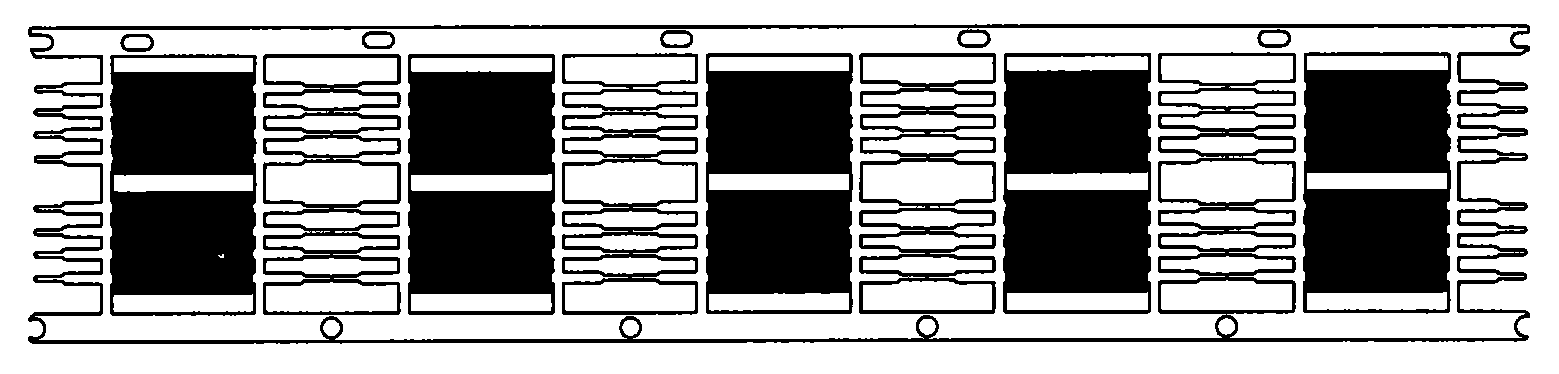

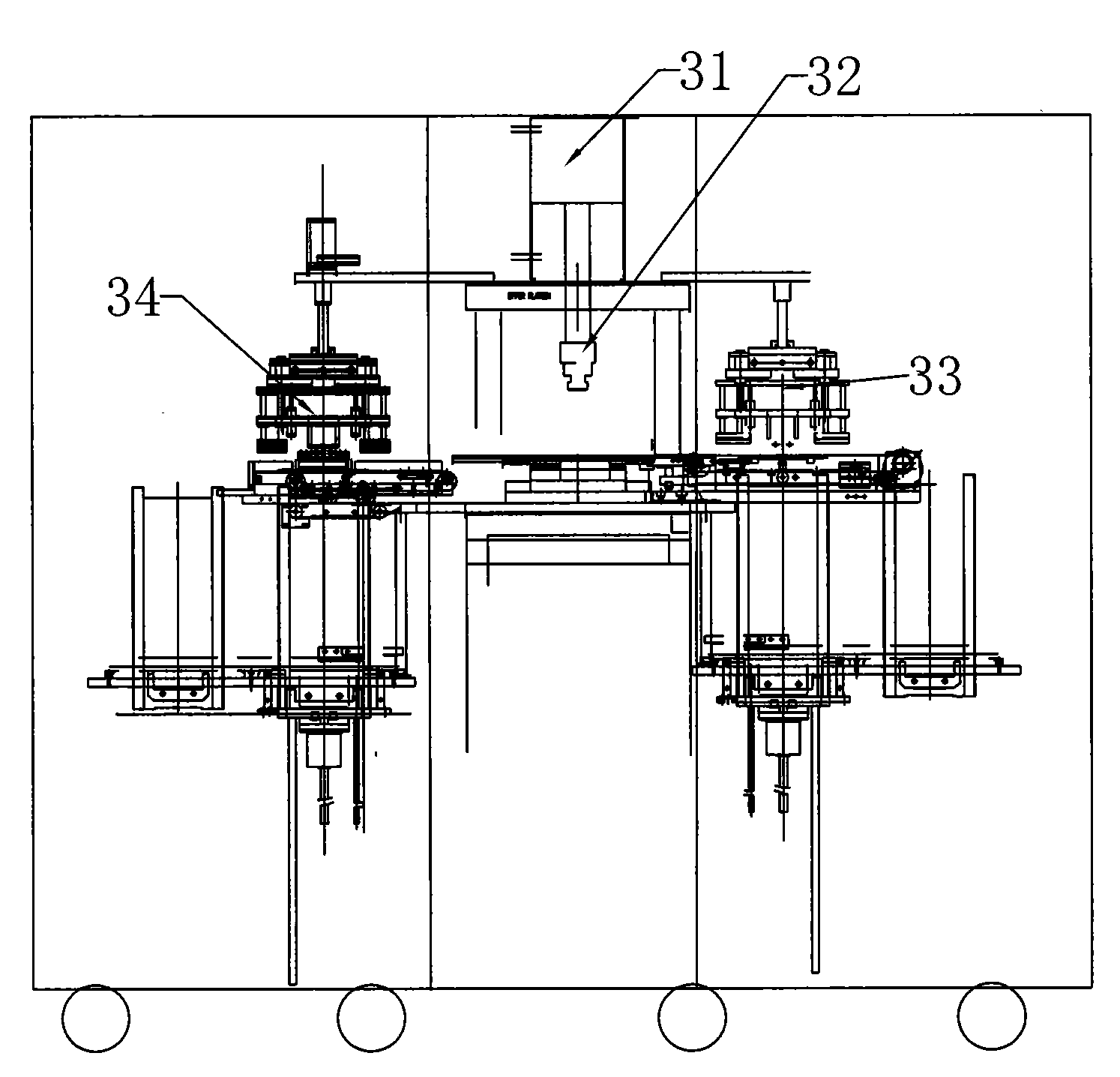

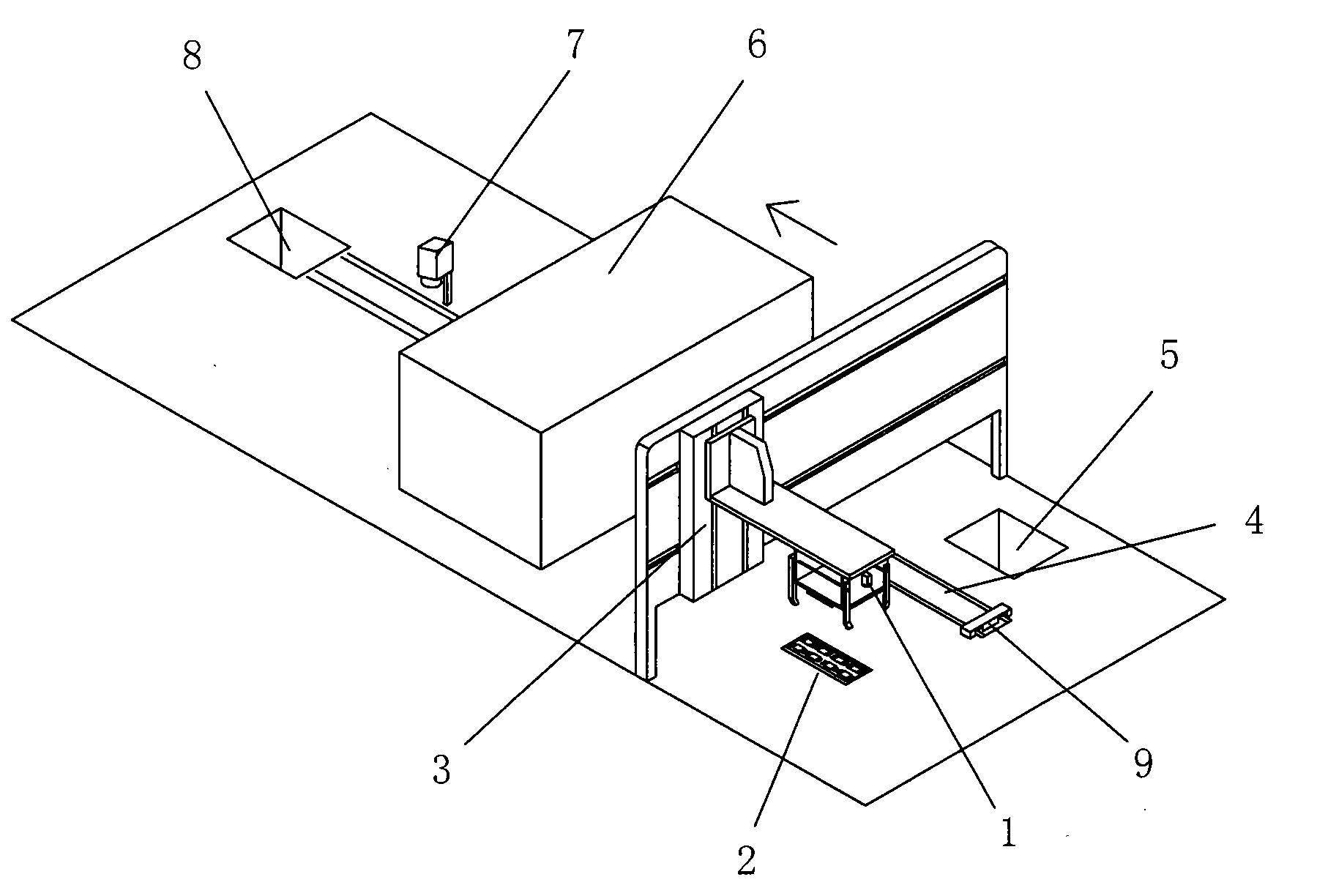

[0030] A control system of an integrated circuit rib cutting device, as shown in the figure, includes a main controller, the main controller is provided with a control output connected to the feeding device, and a control output connected to the driving mechanism of the rib cutting device 6 terminal, the control output terminal connected with the receiving device; the main controller sends an instruction to the feeding device, and the feeding device moves the material to the entrance of the rib cutting device 6; the main controller sends an instruction to the driver of the rib cutting device Mechanism, the driving mechanism of the rib cutting device outputs three groups of power through the transmission camshaft 603, and one group of power is output by the eccentric wheel mechanism to complete the punching of the connecting ribs of the circuit pins of the blank by the rib cutting mold 607, and one group of power The power is completed by the transmission bridge cam 608 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com