Method and system for recycling sliding energy of automobile

An energy recovery and automotive technology, applied in the automotive field, can solve problems such as inability to apply hybrid power systems or transmission systems, and the calibration parameters are not intuitive enough to ensure driving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

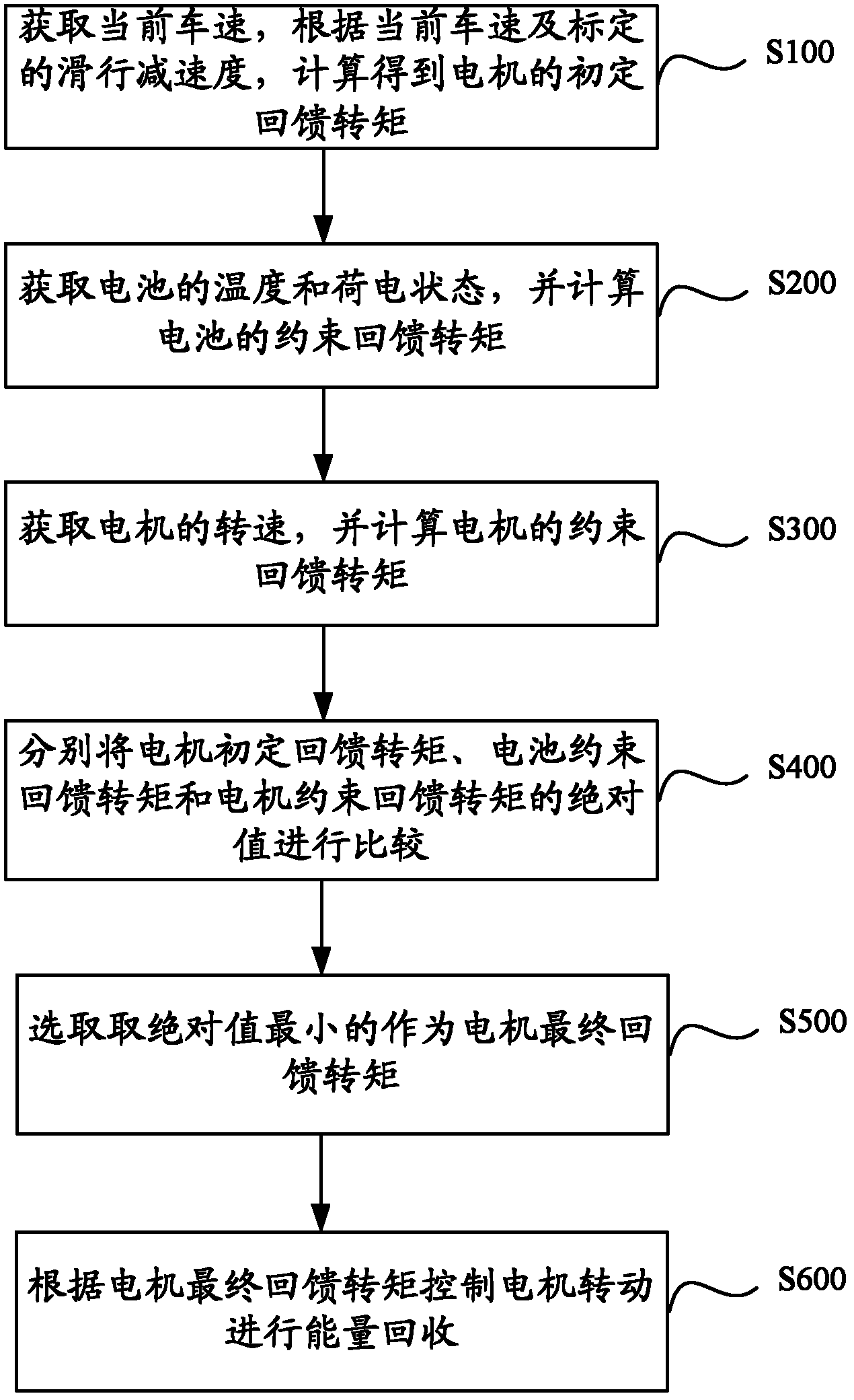

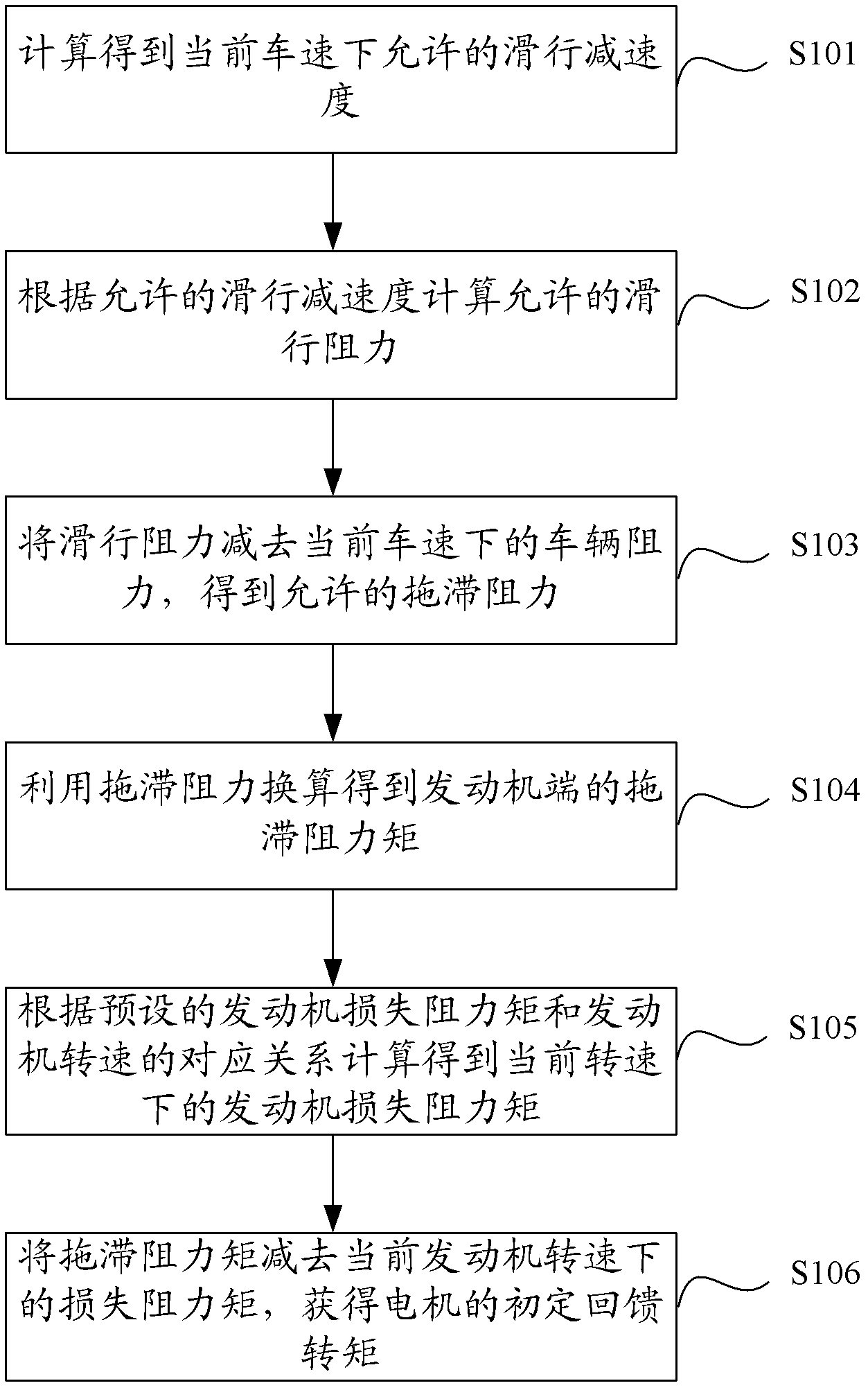

[0051] figure 1 It is a schematic flowchart of a method for recovering energy from vehicle coasting provided in the embodiment of the present application.

[0052] Such as figure 1 As shown, the method includes the following steps:

[0053] S100: Obtain the current vehicle speed, calculate the dragging resistance torque at the engine end according to the current vehicle speed and the calibrated coasting deceleration, and calculate the initial feedback torque of the motor according to the dragging resistance torque.

[0054]When recovering the sliding energy of the vehicle, it is first necessary to obtain the current speed of the vehicle, and determine how to recover the sliding energy according to the magnitude of the current speed. The calibrated coasting deceleration refers to the corresponding relationship between the allowed coasting deceleration and the vehicle speed. In practical applications, it can be obtained through experimental calibration.

[0055] In the embodi...

Embodiment 2

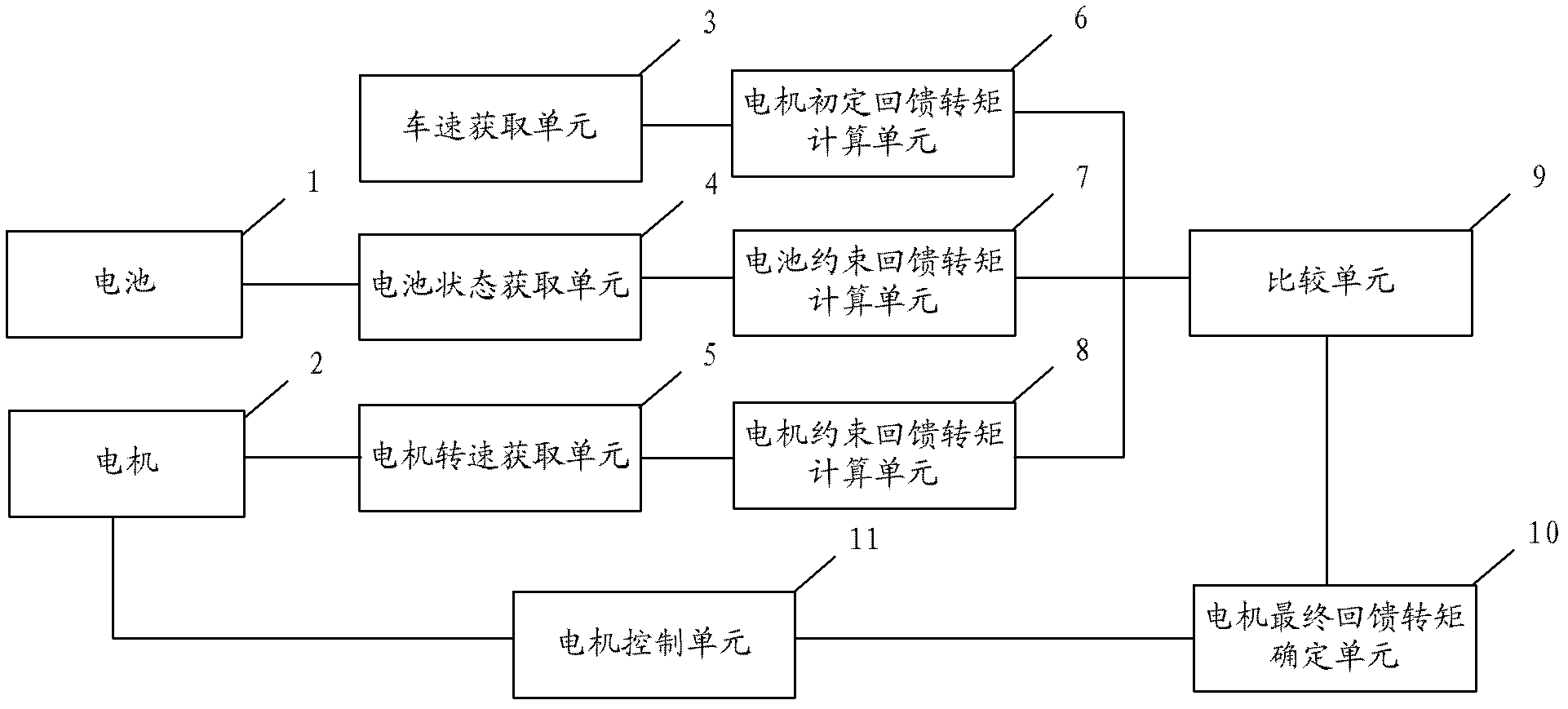

[0081] On the basis of the previous embodiment, the present application also provides a vehicle sliding energy recovery system, image 3 It is a schematic structural diagram of a vehicle coasting energy recovery system provided in an embodiment of the present application.

[0082] Such as image 3 As shown, 1 in the figure is the battery, and 2 is the motor. The vehicle coasting energy recovery system includes: vehicle speed acquisition unit 3, battery status acquisition unit 4, motor speed acquisition unit 5, motor initial feedback torque calculation unit 6, battery constraint Feedback torque calculation unit 7 , motor constraint feedback torque calculation unit 8 , comparison unit 9 , motor final feedback torque determination unit 10 and motor control unit 11 .

[0083] The vehicle speed obtaining unit 3 is connected with the vehicle engine or the wheels, and is used to obtain the current vehicle speed of the vehicle. In practical applications, the vehicle speed obtaining u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com