Weather-resistant white master batch, weather-resistant polyester material and preparation methods of weather-resistant white master batch and weather-resistant polyester material

A technology of white masterbatch and weather resistance, applied in the field of polyester materials, can solve the problems of improving the weather resistance of PET, and achieve the effects of good weather resistance, simple production process and good thermodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of weather-resistant white masterbatch provided by the invention comprises the following steps:

[0038] (1) Add polyester chips, white pigments, light stabilizers and UV absorbers to a twin-screw extruder through a weight loss scale for full mixing, homogenization and devolatilization to obtain a molten mixture;

[0039] (2) The molten mixture obtained in step (1) is pressurized by a melt pump and filtered through a filter to obtain a melt;

[0040] (3) Pull the molten material obtained in step (2), cool it through a water tank, and then pass it through a water eliminator and hot air to dry continuously to remove water, cut into pellets, and pack to obtain the weather-resistant white masterbatch.

[0041] The processing temperature of each zone of the twin-screw extruder is 220-320° C., the rotation speed of the main engine is 400-800 rpm, and the aperture of the filter screen is 20-100 μm. The water temperature of the water tank is 10-25°C, and...

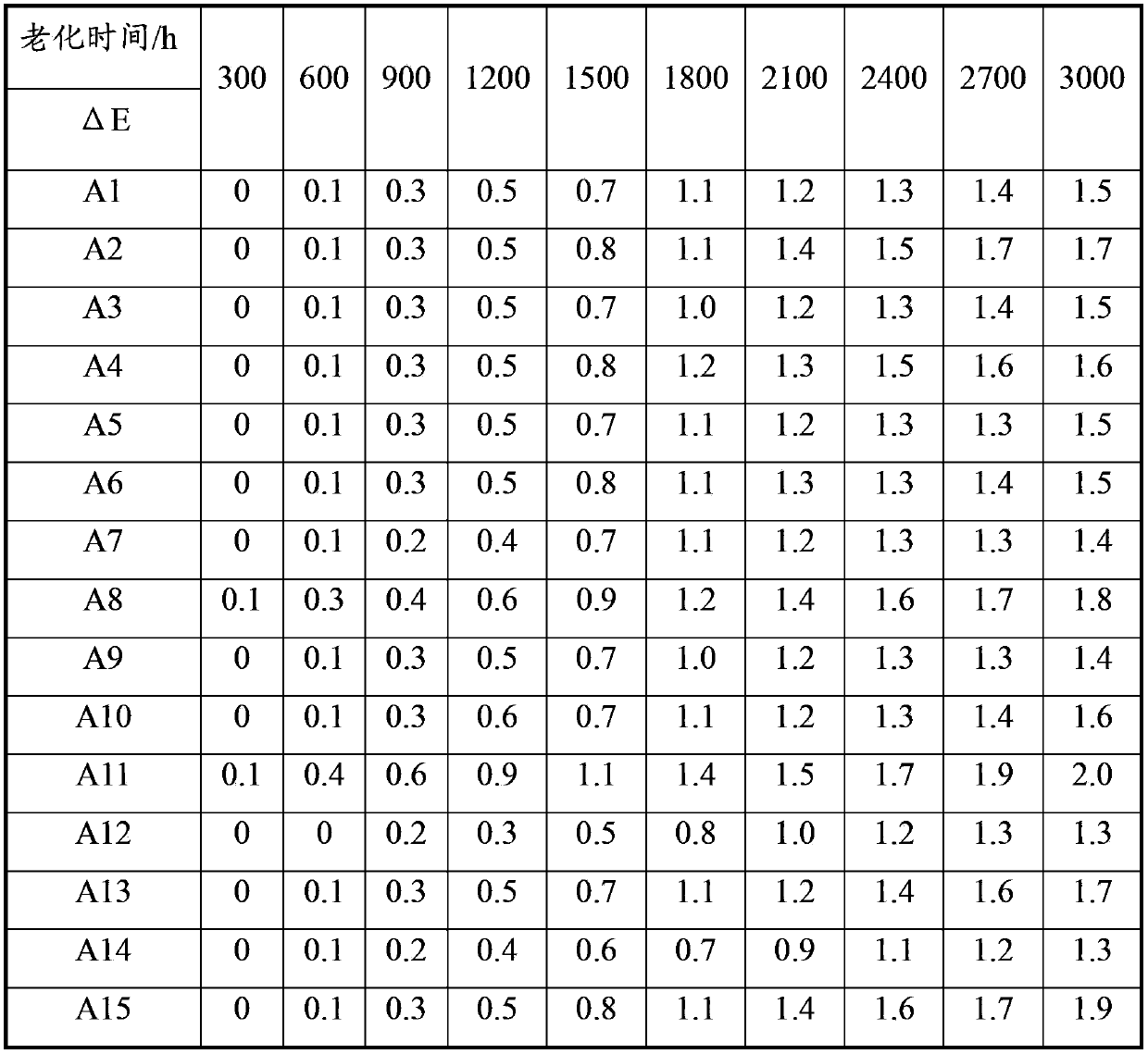

Embodiment 1

[0047]In terms of parts by mass, 100 parts of Daguang PET polyester chips, 55 parts of rutile titanium dioxide, 1 part of poly(1-hydroxyethyl-2,2,6,6-tetramethyl-4-hydroxypiper Pyridine) succinate and 1 part of 2-(2'-hydroxyl-3'-isobutyl-5'-tert-butylphenyl)benzotriazole are added to the twin-screw extruder through a weight loss scale, and each zone is processed The temperature is 220-300°C, the rotation speed of the main engine is 400rpm, and the pore size of the filter screen is 50μm. Through the shearing and mixing of the screw, the pigment and additives are uniformly dispersed in the resin, and then the weather-resistant PET white masterbatch A1 is obtained through granulation, drying, packaging and other processes.

Embodiment 2

[0049] In terms of parts by mass, 100 parts of Daguang PET polyester chips, 55 parts of rutile titanium dioxide, 1 part of poly(1-hydroxyethyl-2,2,6,6-tetramethyl-4-hydroxypiper Pyridine) succinate and 1 part of 2-(2H-benzotriazol-2-yl)-6-dodecyl-4-cresol are added to the twin-screw extruder through a weight loss scale, and the temperature in each zone of the process is 220 -300°C, the speed of the main engine is 400rpm, and the pore size of the filter screen is 50μm. Through the shearing and mixing of the screw, the pigment and additives are uniformly dispersed in the resin, and then the PET weather-resistant white masterbatch A2 is obtained through granulation, drying, packaging and other processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com