Apparatus for lifting and turning slag pot

A technology of tipping device and steel slag tank is applied in the field of steel-making slag treatment, which can solve problems such as instability and achieve the effect of being less prone to safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

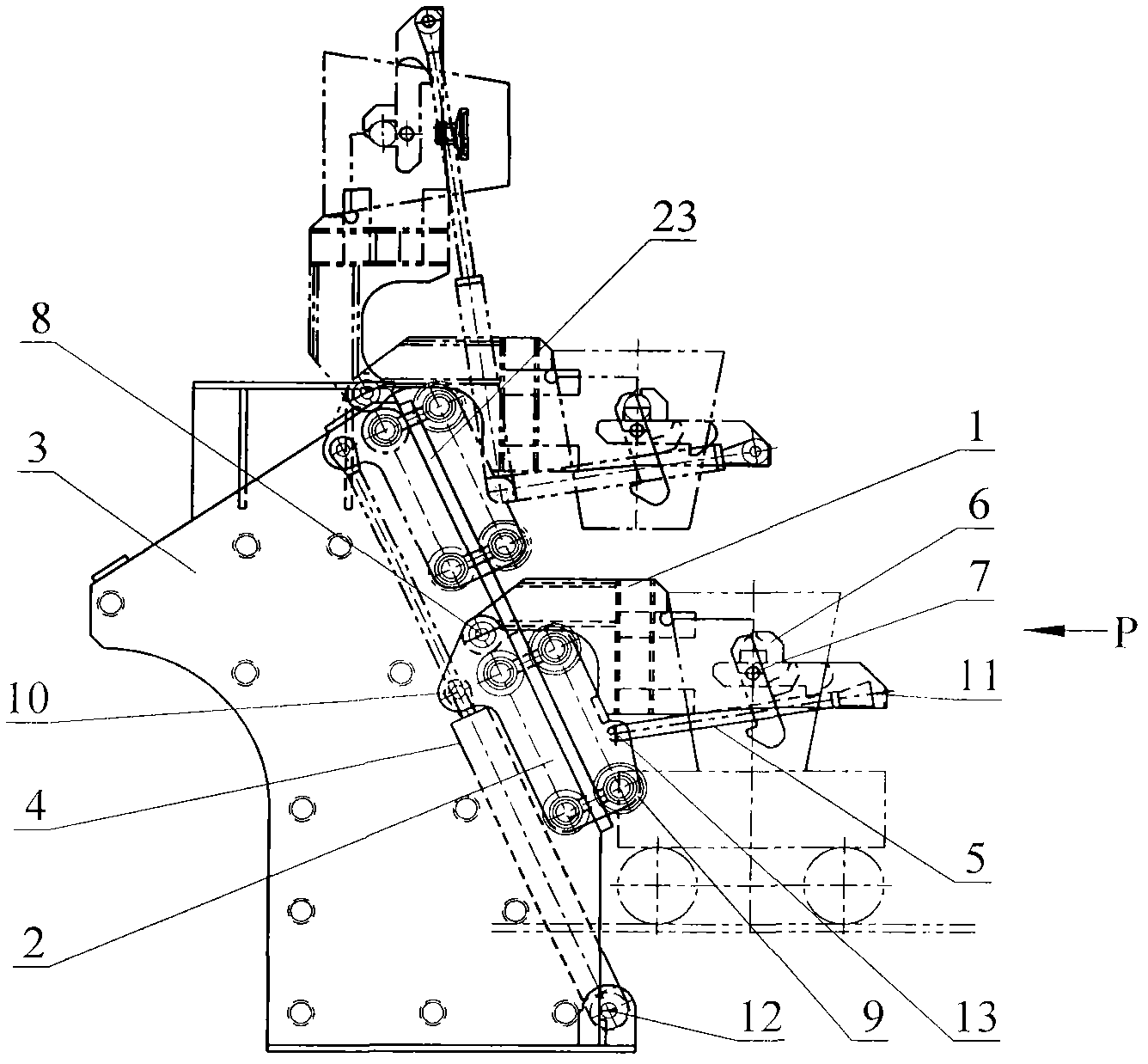

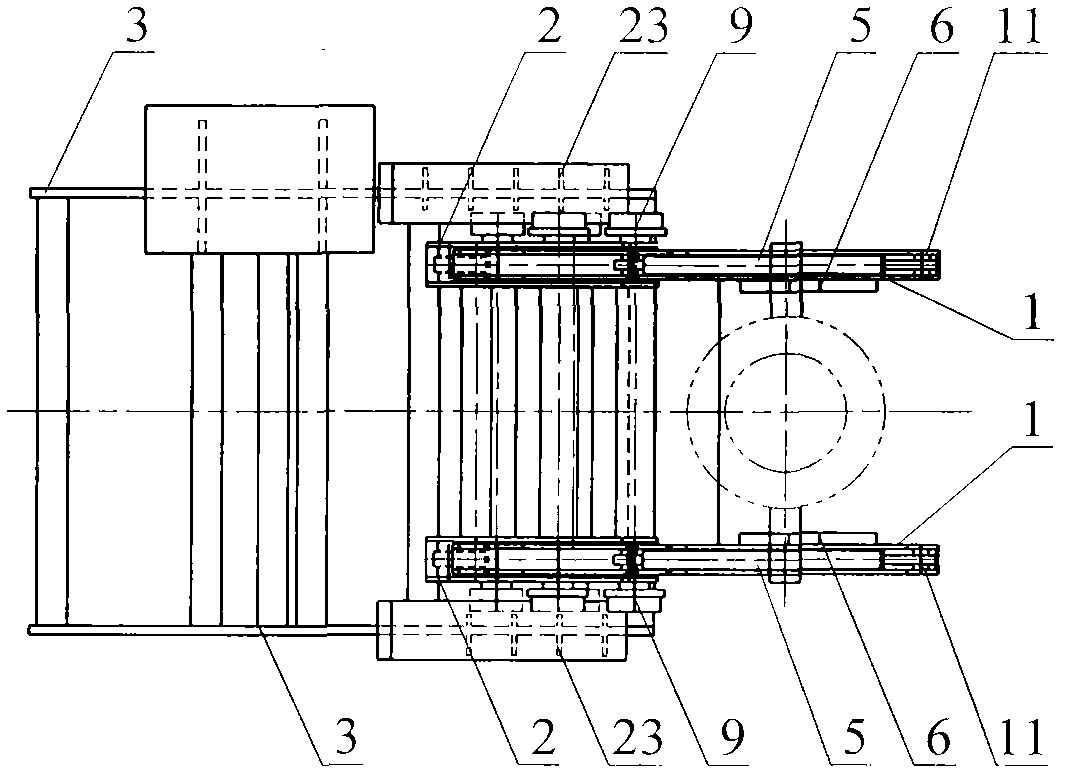

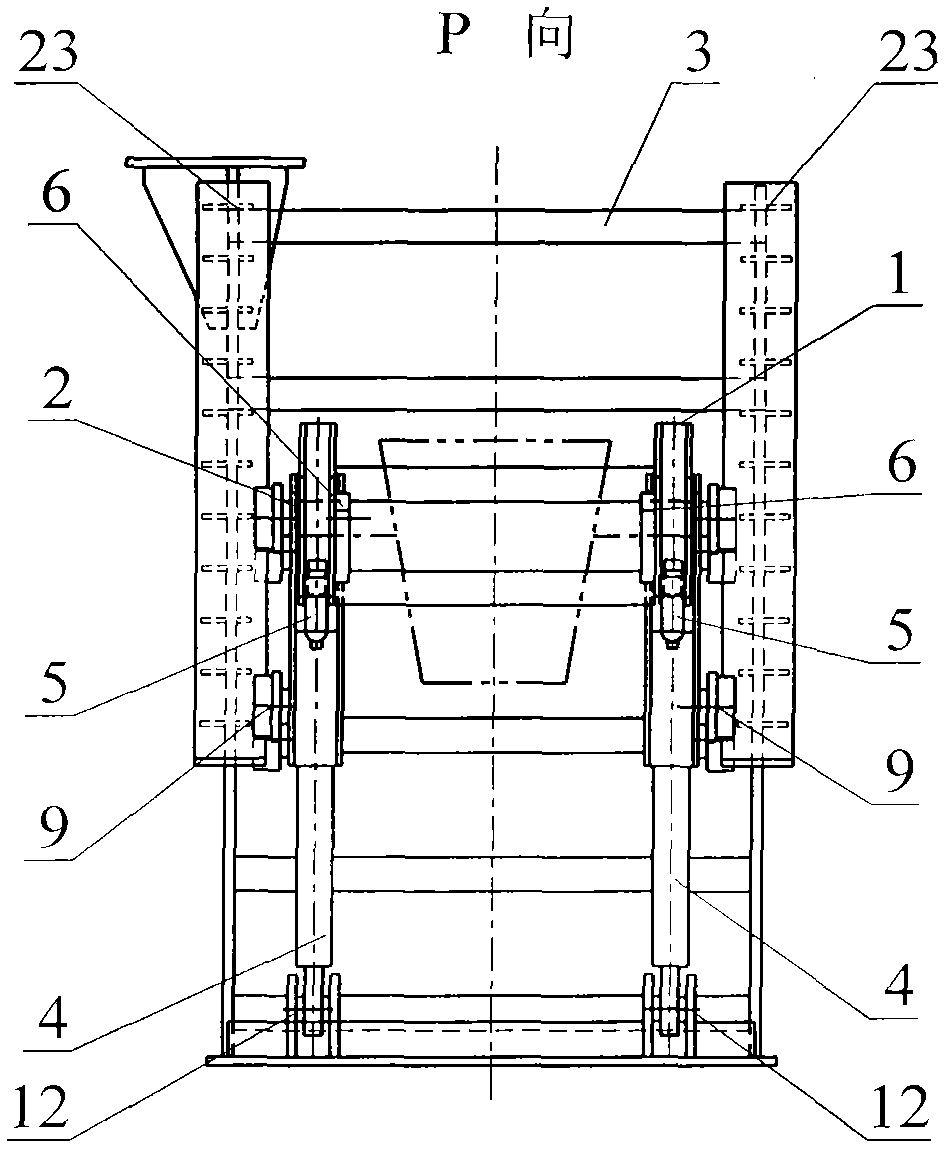

[0032] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 , figure 2 and image 3 As shown, the steel slag tank lifting and tilting device in this embodiment includes: a bracket 1, a lifting trolley 2, a bracket 3, two lifting hydraulic cylinders 4, two tilting hydraulic cylinders 5 and a pair of slag tank trunnion locking blocks 6 ;

[0034] The bracket 1 is installed between the two guide rails 23 on the bracket 3, the roller 9 of the lifting trolley 2 is in rollable contact with the front and back of the two guide rails 23 of the bracket 3, and the two sides of the upper left part of the lifting trolley 2 are connected with the lifting hydraulic cylinder respectively. 4 The piston rod head earring is hinged through the first pin 10, and the top of the lifting trolley 2 is hinged with the left part of the bracket 1 through the third pin 8;

[0035] The tail of the lifting hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com