A bearing bush hydraulic flanging machine

A technology of flanging machine and hydraulic mechanism, which is applied in the field of bearing bush hydraulic flanging machine, which can solve the problems of hard fixing of bearing bush and poor processing effect of bearing bush, and achieve good quality, cost saving, space saving and fine processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

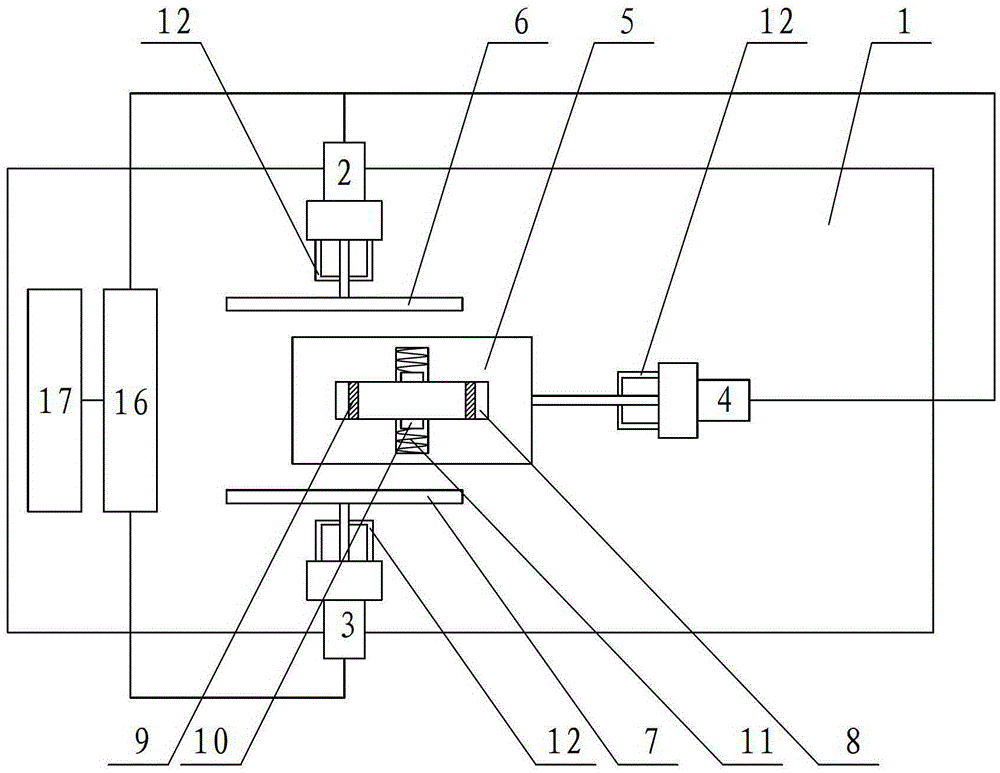

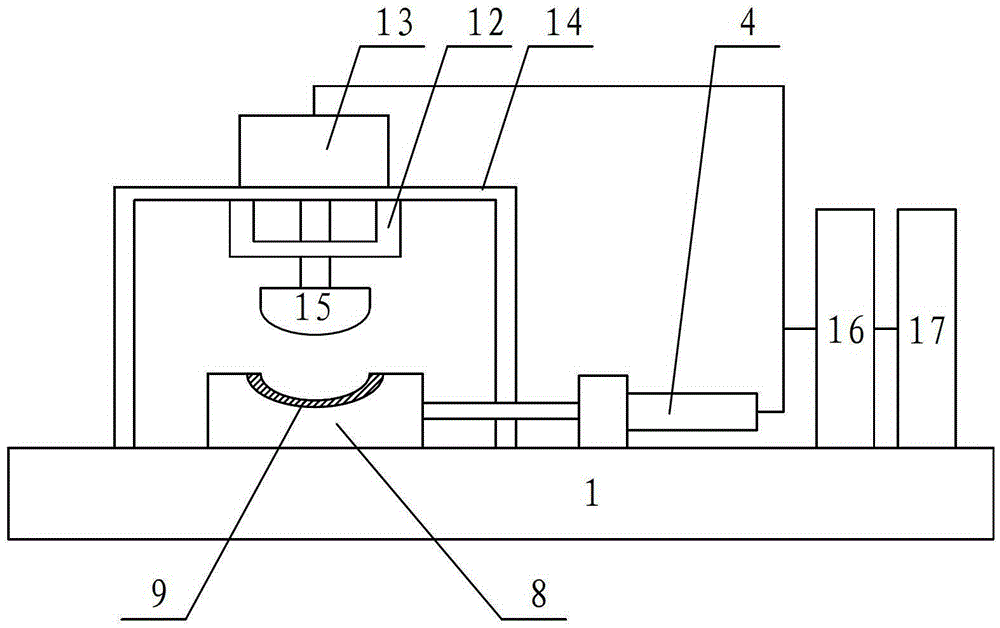

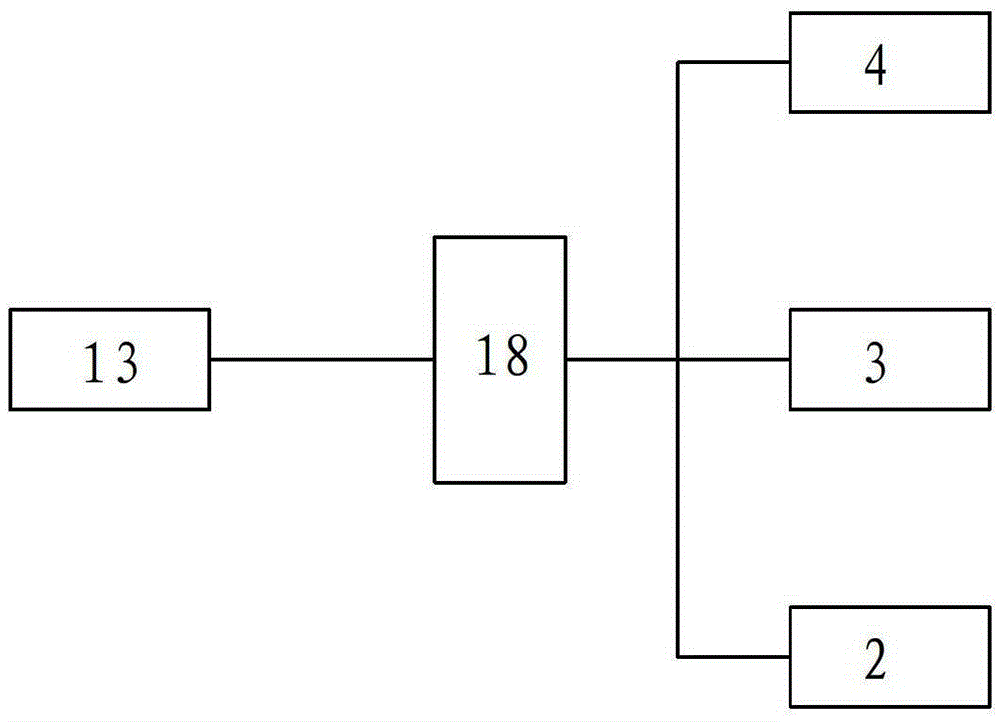

[0016] A bearing bush hydraulic flanging machine is proposed, including a base 1 on which a first hydraulic mechanism 2, a second hydraulic mechanism 3, a third hydraulic mechanism 4, a fourth hydraulic mechanism 13, a hydraulic cylinder 17, an oil station 16, a numerically controlled System 18, numerical control system 18 controls and connects the first hydraulic mechanism 2, the second hydraulic mechanism 3, the third hydraulic mechanism 4, the fourth hydraulic mechanism 13, and the hydraulic cylinder 17 supplies the first hydraulic mechanism 2 and the second hydraulic The mechanism 3, the third hydraulic mechanism 4 and the fourth hydraulic mechanism 13 supply oil, the base 1 is provided with a movable plate 5, the fourth hydraulic mechanism 13 is fixed above the movable plate 5 through a bracket 14, and the fourth hydraulic mechanism 13 is telescopically connected to the top 15, The bottom of the plug 15 is provided with a protrusion matching the inner surface of the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com