Lens assembly equipment and method of assembling lens

A technology for assembling equipment and lenses, which is applied in the direction of assembly machines, metal processing equipment, installation, etc., can solve problems that need to be improved, and achieve the effects of improved assembly efficiency, fast moving speed, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

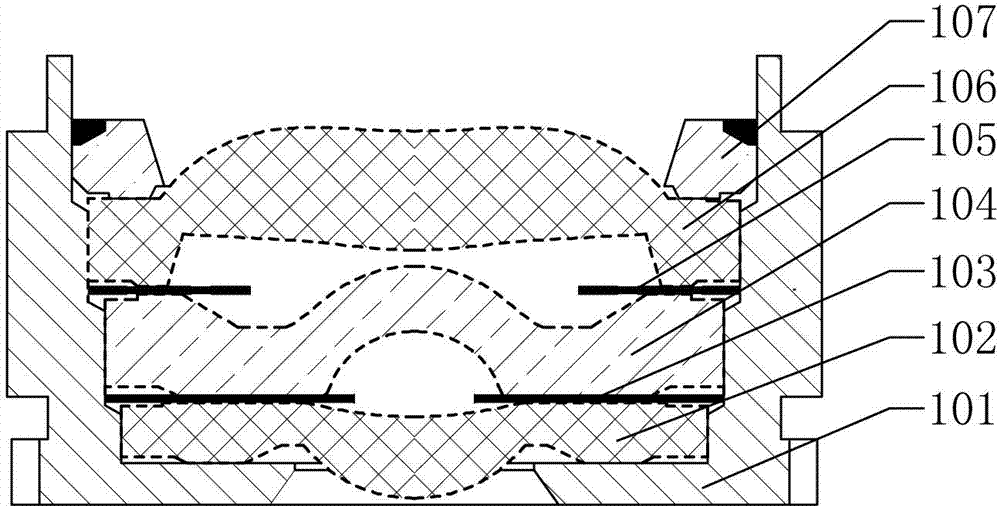

[0072] Such as figure 1 As shown, this embodiment takes assembling a seven-piece camera lens as an example to illustrate the present invention. Of course, the present invention can also be used for three-piece, five-piece, nine-piece or other camera lens assembly. The seven-piece camera lens includes a lens barrel 101, a first lens 102, a lock code one 103, a second lens 104, a lock code two 105, a third lens 106, and a pad that are sequentially stacked in the lens barrel 101 from bottom to top. 片107.

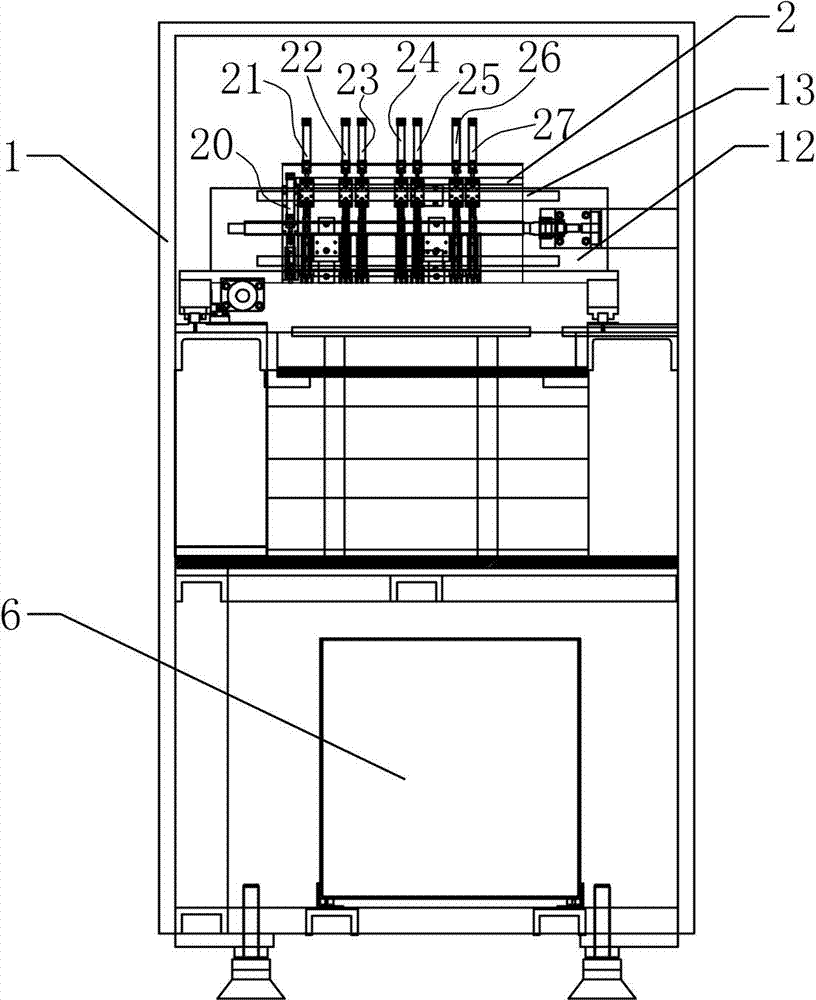

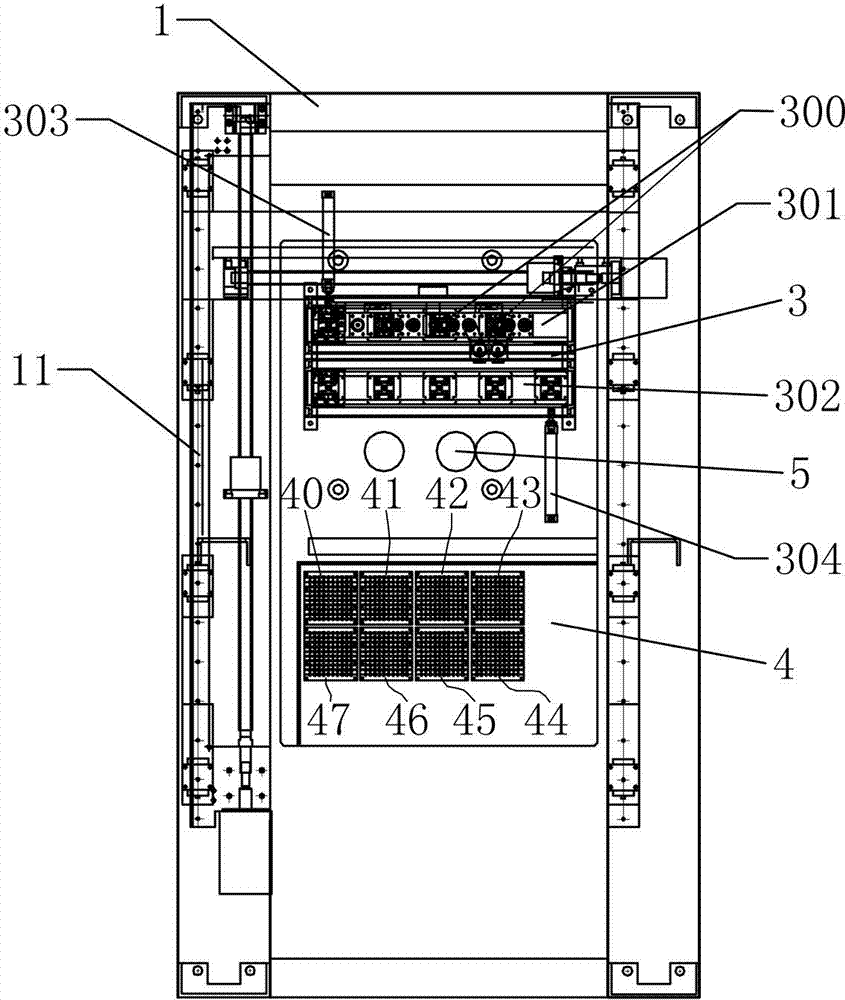

[0073] Such as Figure 2 to Figure 6 As shown, a lens assembly equipment includes a rack 1 provided with an assembly platform. The rack 1 is provided with an assembly unit 2 that can move on a plane parallel to the assembly platform. The assembly unit 2 includes eight The nozzle mechanism that moves in the direction of the assembly platform, one of which is the nozzle mechanism for taking out the lens; the assembly platform is equipped with a jig revolving platform 3, which is equ...

Embodiment 2

[0119] The difference between this embodiment and the first embodiment is as follows: Picture 10 , Picture 11 As shown, the gantry frame 12 is provided with two assembly units 2. The longitudinal movement of the two assembly units 2 is carried by the gantry frame 12 as a carrier. The two assembly units 2 are jointly controlled by a control unit 6 and are synchronized in the gantry frame. 12 moves laterally on the transverse rail 13. Correspondingly, there are two jig revolving platforms 3 and a loading platform 4 on the assembly platform. Of course, on the premise of not affecting the precision control, multiple assembly units 2 can be provided on the gantry frame 12, and correspondingly multiple jig swivel platforms 3 and feeding platforms 4 can be provided on the assembly platform. Therefore, the present invention has Better scalability, which can greatly improve its assembly efficiency.

[0120] The rest of the content of this embodiment is the same as that of the first embo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap