Core drill and coring method

A technology for core drilling and core drilling bits, which is applied in earth-moving drilling, extraction of undisturbed core devices, wellbore/well components, etc., can solve problems such as inability to observe cores, and achieve the effect of avoiding complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

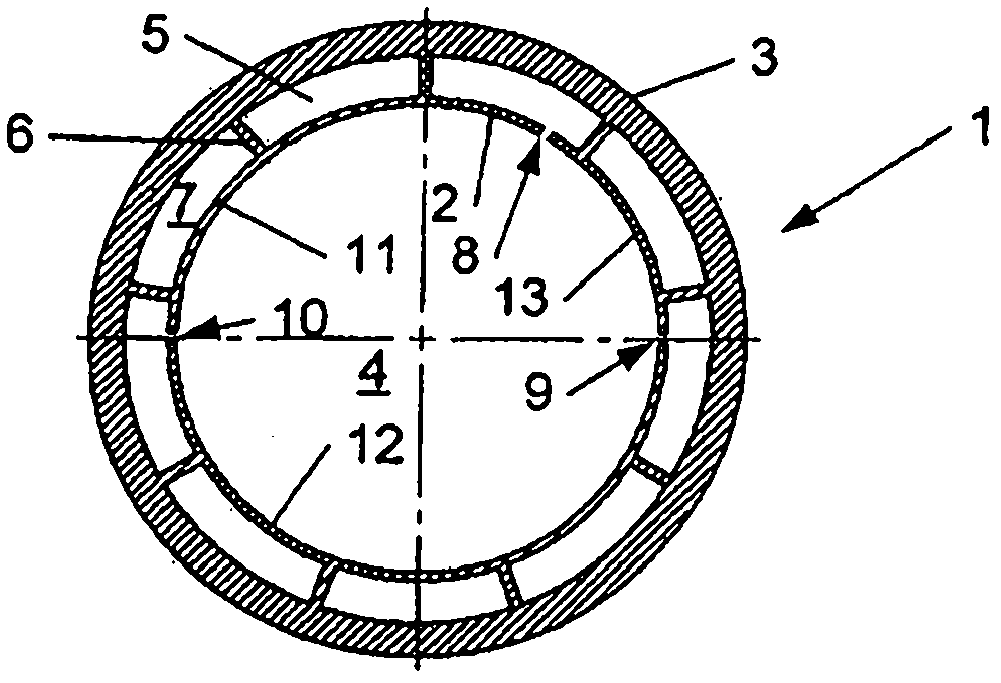

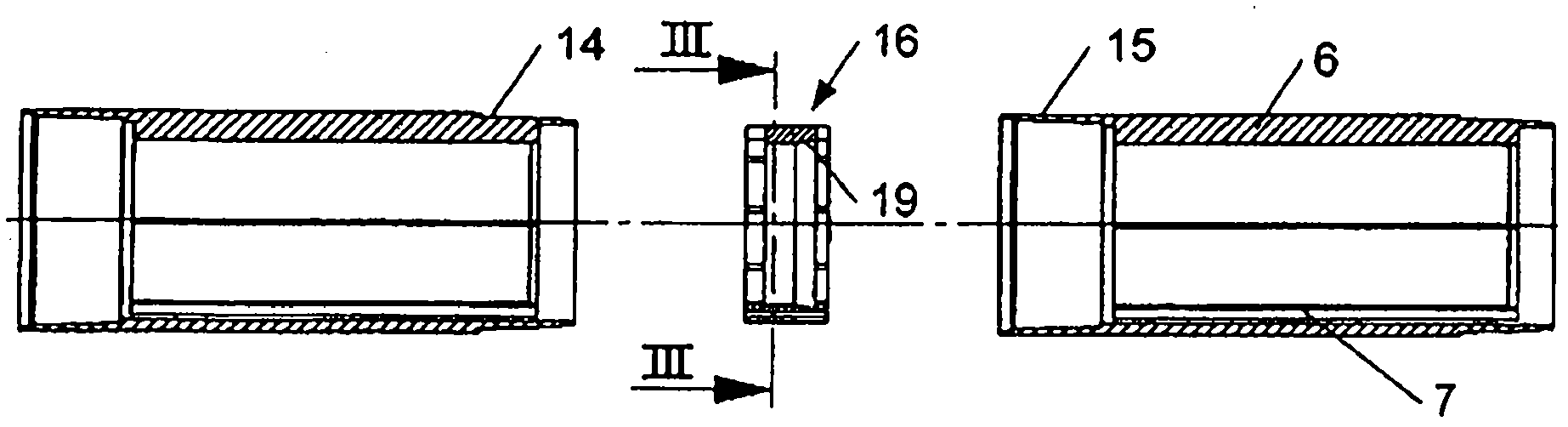

[0033] In the various figures, the same or similar elements have the same reference numerals.

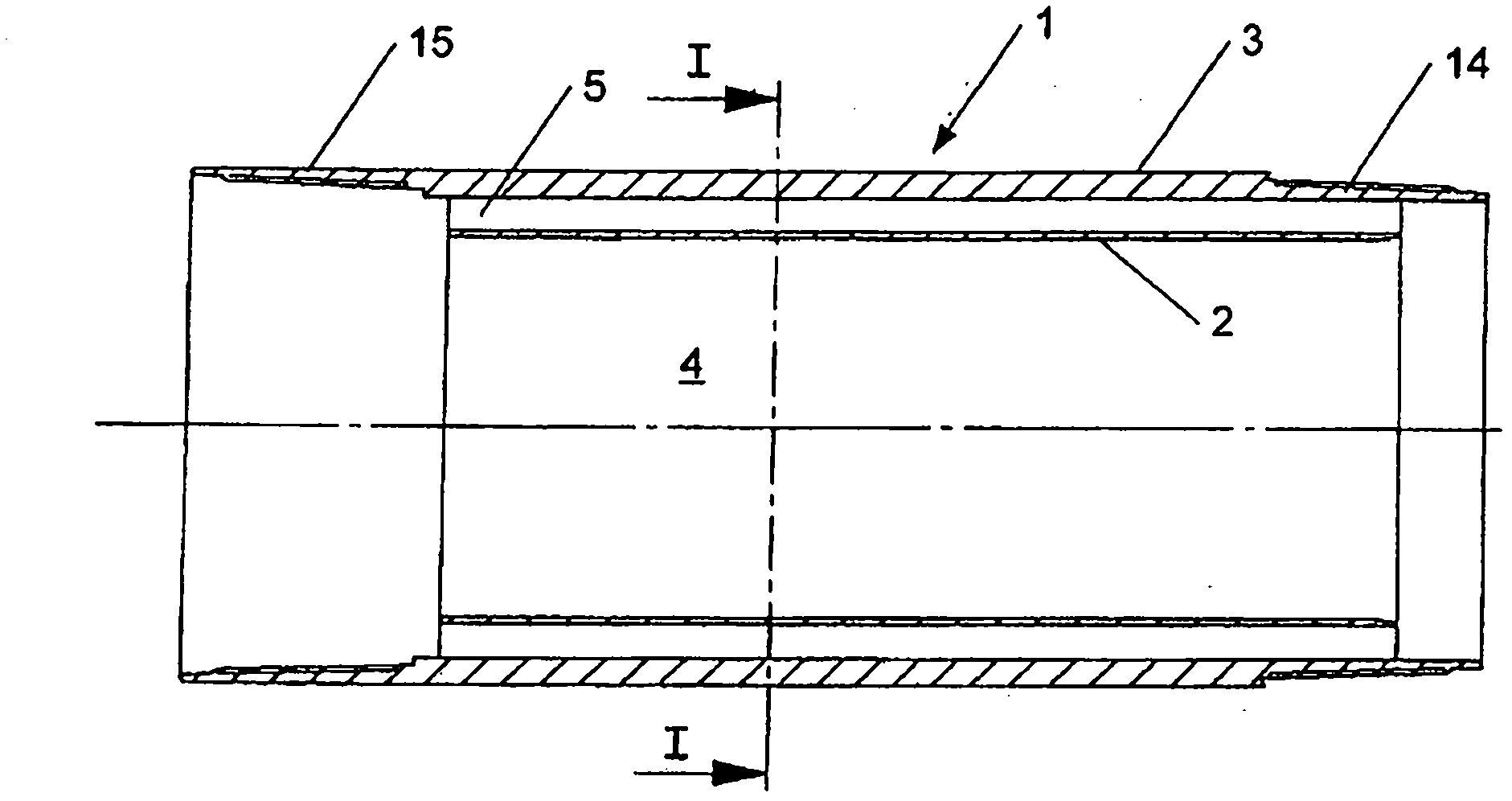

[0034] Such as figure 1 and 2 clearly shown in ( figure 1 and 2 An example of an inner coring tube 1 that can be used in the inventive coring drill or coring method is shown), the inner coring tube 1 being designed in the form of a double-walled tube. It comprises an inner tubular wall 2 and an outer tubular wall 3 . The inner tubular wall 2 will receive the core in its cavity 4 . It is housed coaxially inside the outer tubular wall 3 while being held radially at a distance therefrom so as to form an annular space 5 between the inner and outer tubular walls. Especially as figure 2 As shown in , the tubular walls 2 and 3 are firmly connected to each other so as to form a one-piece assembly.

[0035] The shown inner core tube is preferably capable of being manufactured from metal or plastic material, or from a material based on metal or plastic material. Preferably it can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com