Device for preventing mud sand from entering bottom end of buoyancy vertical pipe of net cage frame

A buoyancy and riser technology, which is applied in the field of aquaculture cage technology and equipment, can solve the problems of siltation in the cage, blockage of the opening under the valve core, loss of the self-balancing and floating function of the cage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

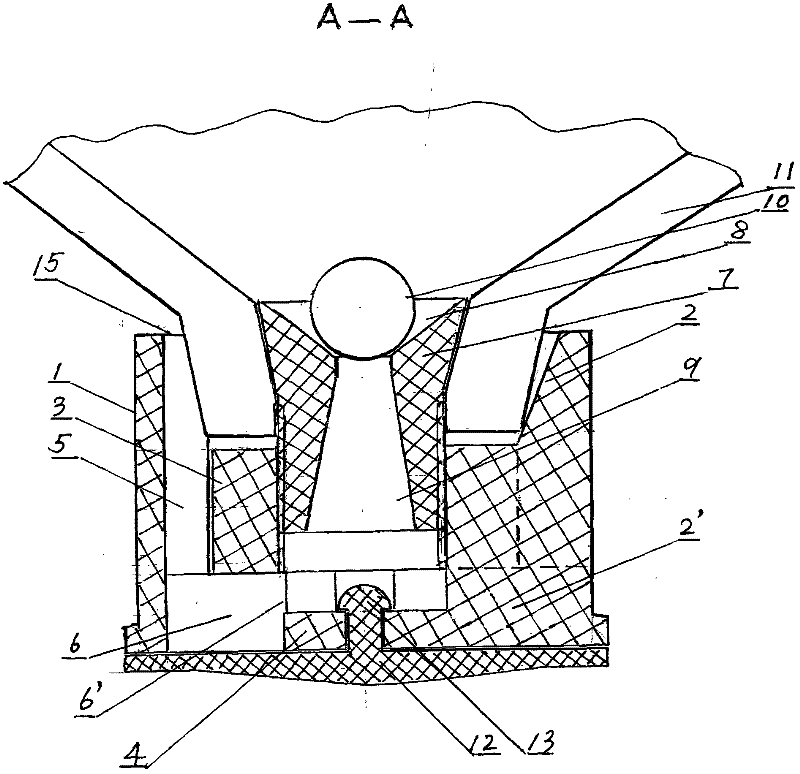

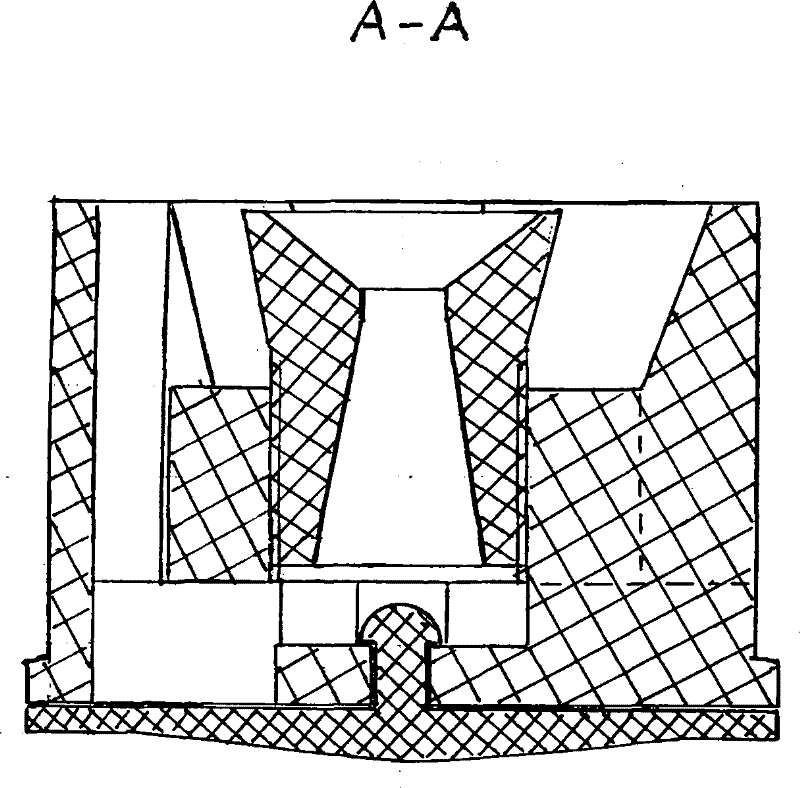

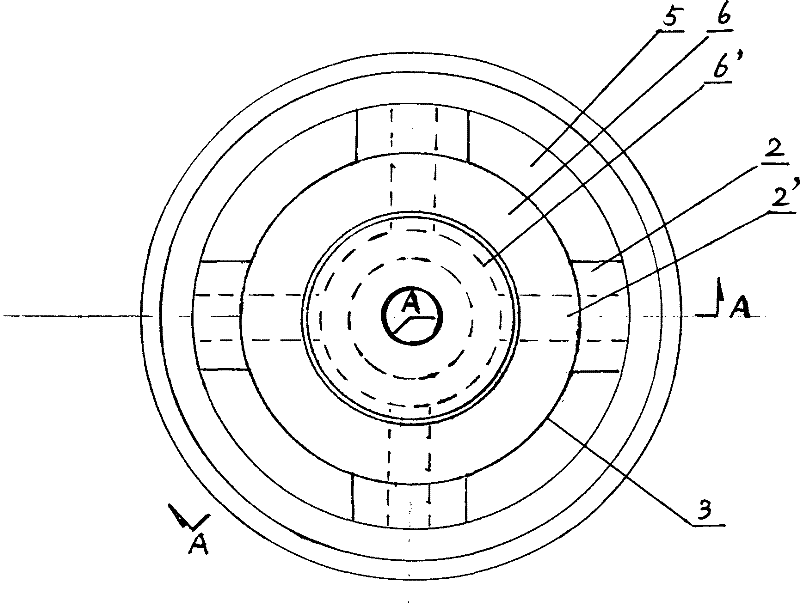

[0014] The accompanying drawings of the description of the present invention provide a specific embodiment. The invention is attached figure 1 , 2 , Shown in 3, 4, 5, its shape is an upper opening cylinder 1, and its lower opening has an elastic cover plate 12. A plurality of vertical ribs 2 are evenly distributed radially in the cylinder body. The outer edge of the vertical edge 2 joins with the inner wall of the cylindrical body 1, and the inner edge of the vertical edge joins with the outer wall of the ring nut 3 at the vertical middle position in the cylindrical body. The inner edge of the vertical edge 2 above the nut 3 is inclined towards the inner wall of the cylinder, the inner edge of the vertical edge 2' of the part below the nut 3 is in contact with the outer wall of the bottom plate 4, and the vertical through holes 5 are formed between the vertical edges 2 , the vertical ribs 2' form the horizontal through hole 6 of the inner opening 6' on the bottom plate 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com