Method for machining centering roller bearing inner ring with oil hole on inside diameter

A technology of self-aligning roller bearings and processing methods, which is applied in metal processing equipment, manufacturing tools, machine tools suitable for grinding workpiece planes, etc., and can solve problems such as processing not meeting standard requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

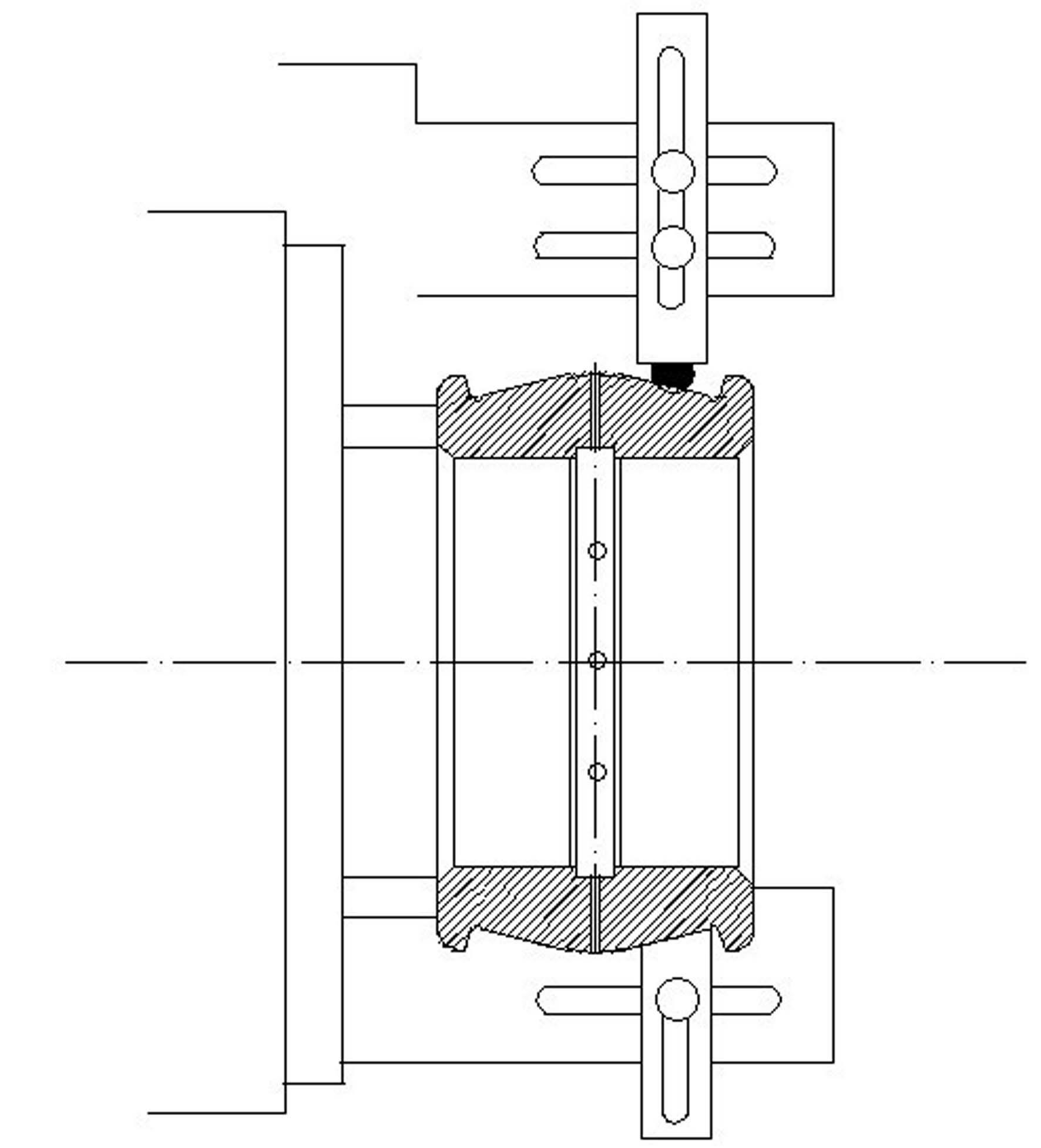

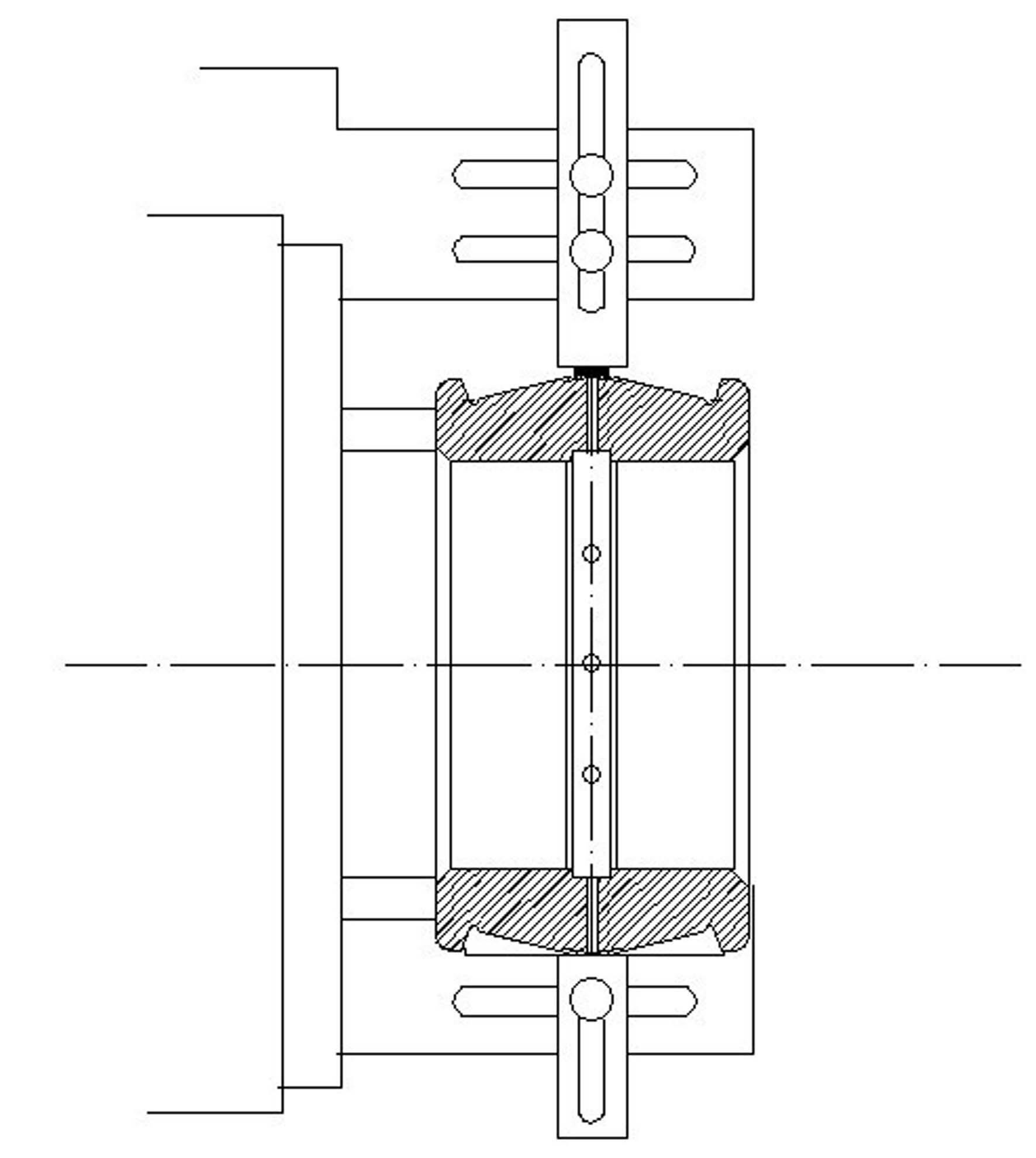

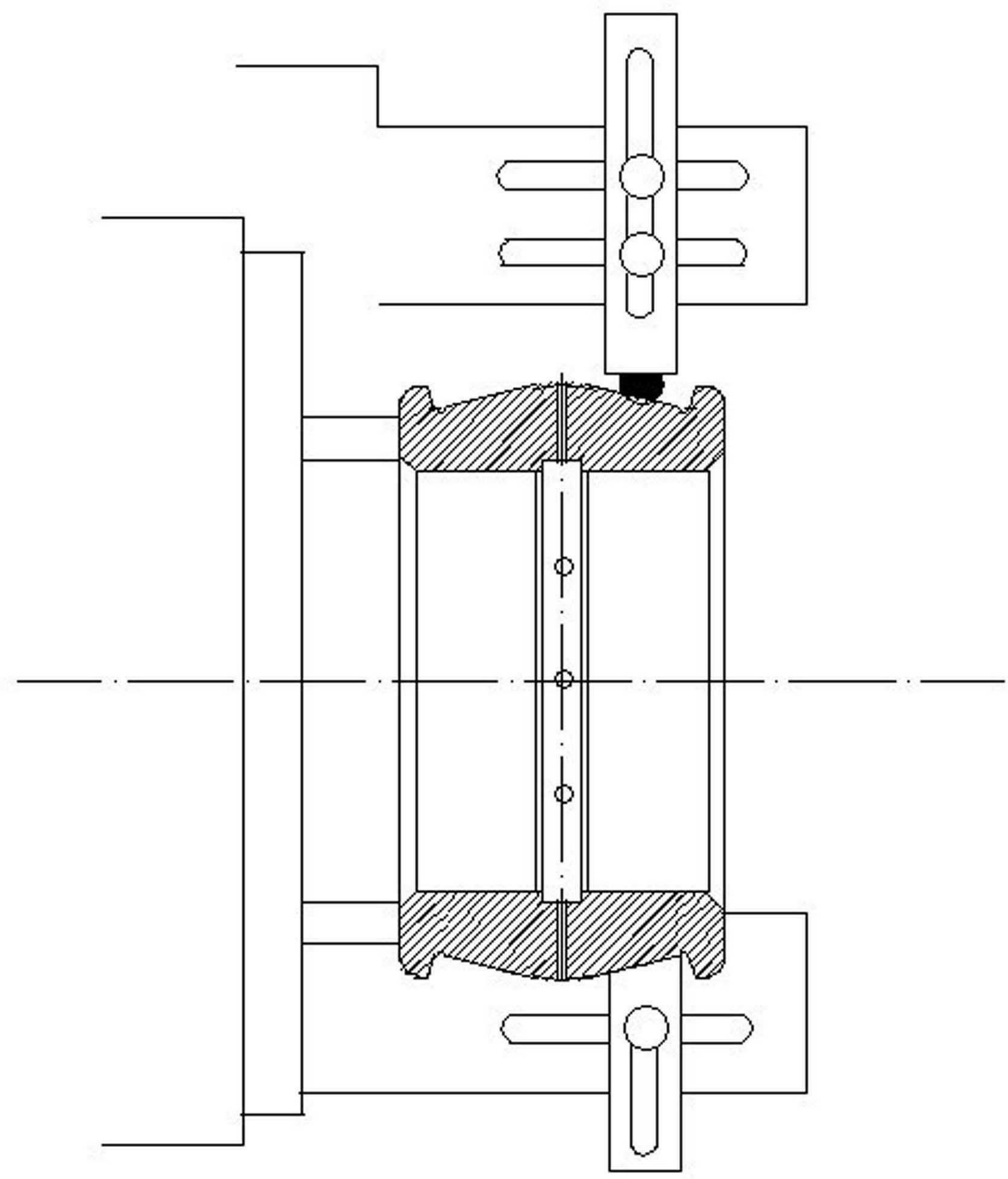

Image

Examples

Embodiment Construction

[0022] A method for processing the inner ring of a self-aligning roller bearing with oil holes in the inner diameter, the processing route is as follows:

[0023] Coarse grinding end face - coarse grinding inner and outer diameter - coarse grinding inner diameter - coarse grinding raceway - additional tempering - fine grinding end face - fine grinding one side raceway - fine grinding inner and outer diameter - fine grinding inner diameter - — Fine grinding the raceway on the other side — Superfine raceway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com