Multi-directional slip sensor

A multi-directional, sensor technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problem that the sliding sensor cannot automatically detect the sliding direction, that is, the sliding deflection angle, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

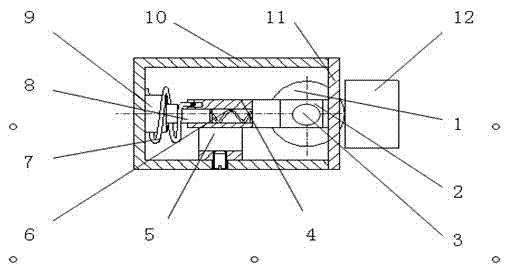

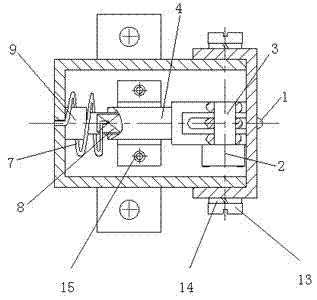

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Such as Figure 1 to Figure 3 As shown, the multidirectional sliding sensor 20 of the present invention includes a sliding wheel 1, a precision potentiometer a2, a mandrel 3, a bracket 4, a shaft support 5, a compression spring 6, a torsion spring 7, a rotating shaft 8, and a precision potentiometer Device b9, box body 10 and box cover 11, fixing screw 13, spring washer 14 and shaft bracket fixing screw 15, etc.

[0019] The box body 10 is connected with a manipulator 21 . The case cover 11 is fixed on the case body 10 with set screws 13 and spring washers 14 .

[0020] A sliding wheel 1 is housed in the box body 10, and the contact between the sliding wheel 1 and the grasping object 12 extends out of the box cover 11, and the sliding wheel 1 is rotationally connected with the fork-shaped structure at the front end of the support 4 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com