High-concentration oxygen generating plant with molecular sieves

Oxygen-generating equipment and molecular sieve technology, applied in the field of high-concentration molecular sieve oxygen-generating equipment, can solve problems such as short life, low oxygen concentration, and reduced volume of adsorption columns, so as to solve the problem of service life and improve the oxygen recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

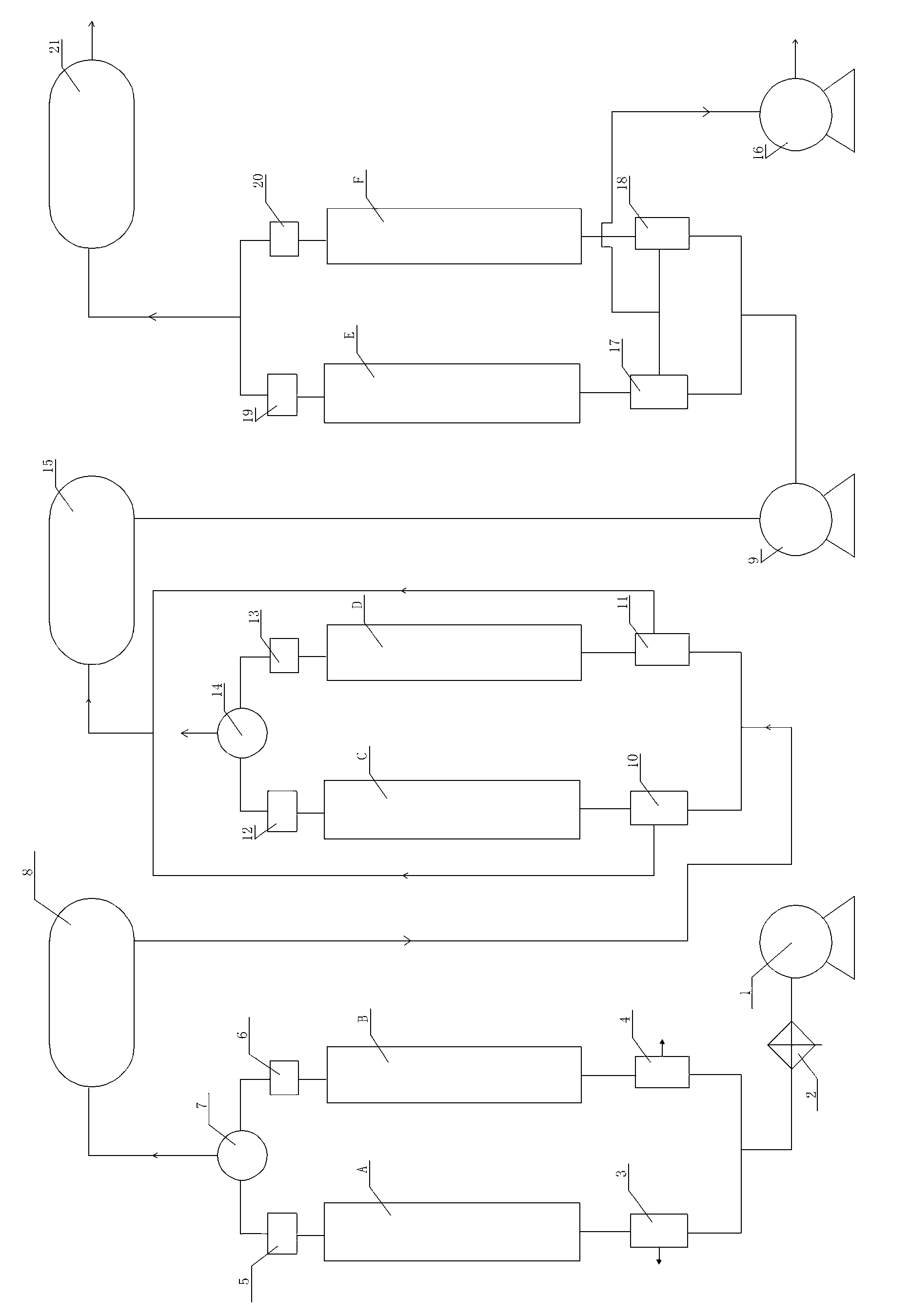

[0017] Attached below figure 1 The present invention will be specifically described.

[0018] Such as figure 1 As shown, the high-concentration molecular sieve oxygen production equipment of the present invention is composed of a dehydration device, an oxygen absorption device and a nitrogen absorption device in series.

[0019] The dehydration device includes: oil-free air compressor (1), steam-water separator (2), two two-position three-way solenoid valves (3, 4), two 5A molecular sieve adsorption columns (A, B), two single To the throttle valve (5, 6), a relief valve (7), the gas tank (8).

[0020] The steam-water separator is an ordinary commercially available steam-water separator, which mainly removes most of the moisture in the air.

[0021] The pore size of 5A molecular sieve is 4.5-5A, which is used to remove the remaining small part of water and some impurities such as carbon dioxide and sulfur dioxide.

[0022] When one 5A molecular sieve adsorption column is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com