Medical health care oxygen machine with molecular sieve PSA

A molecular sieve and oxygen machine technology, which is used in oxygen preparation, respirator and other directions to achieve the effect of extending the replacement cycle, high oxygen recovery rate and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

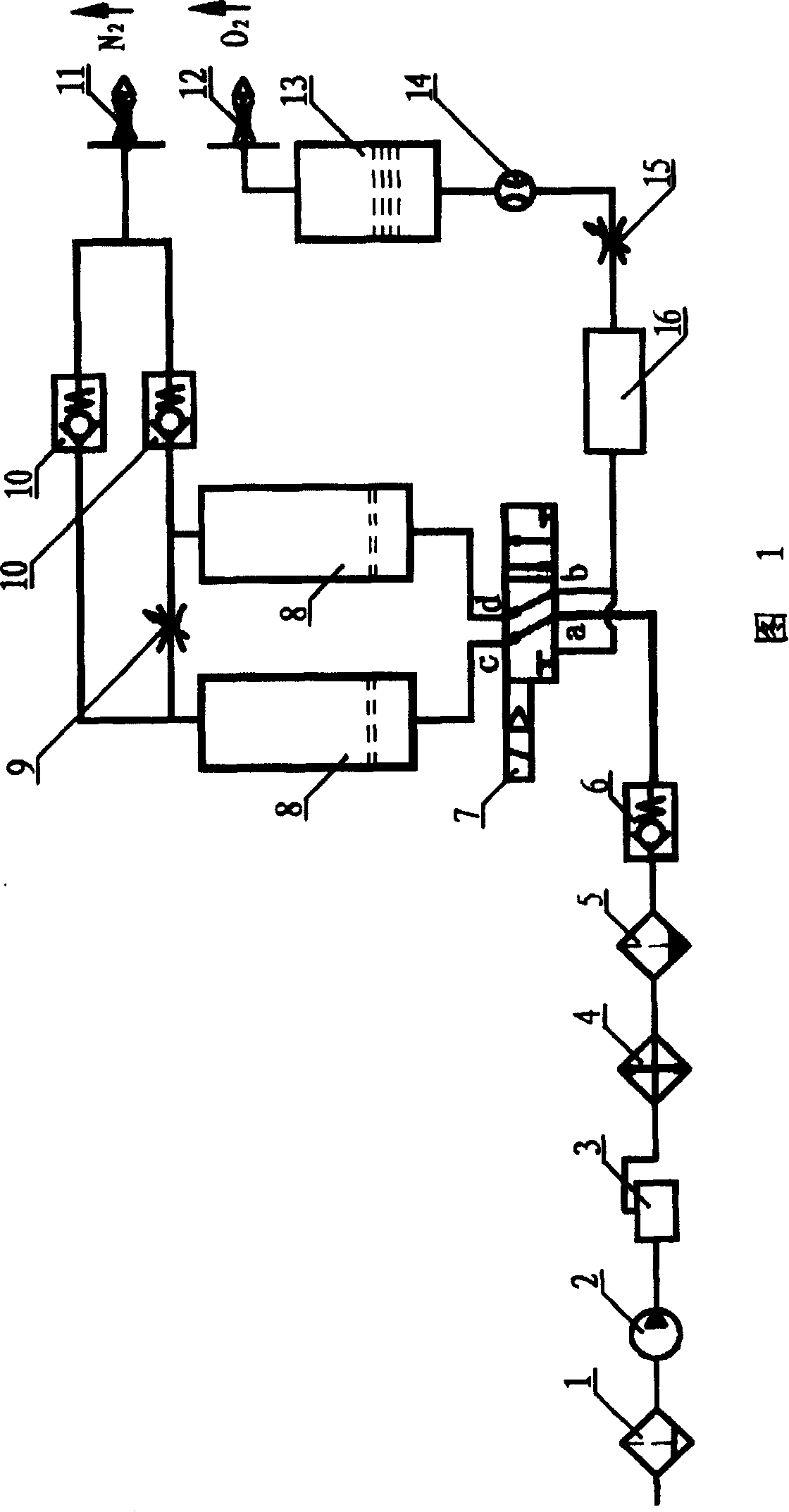

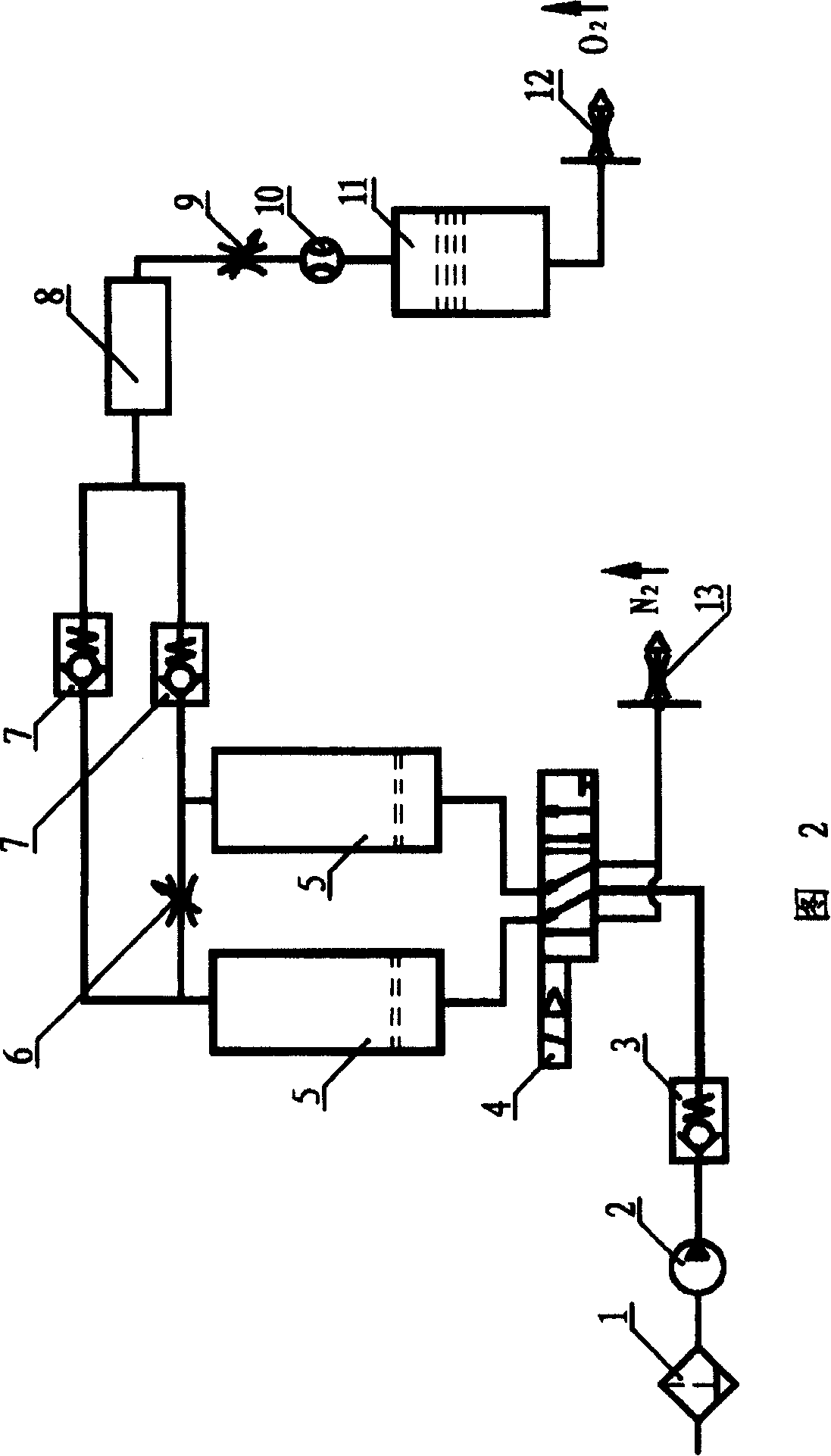

[0013] As shown in accompanying drawing 1, intake filter 1 among the present invention, air compressor 2, cooler 4, automatic drainage filter 5, electromagnetic reversing valve 7, throttle valve 9, buffer tank 16, flowmeter 14 , humidifier 13 and several one-way valves all can adopt standard devices in the prior art.

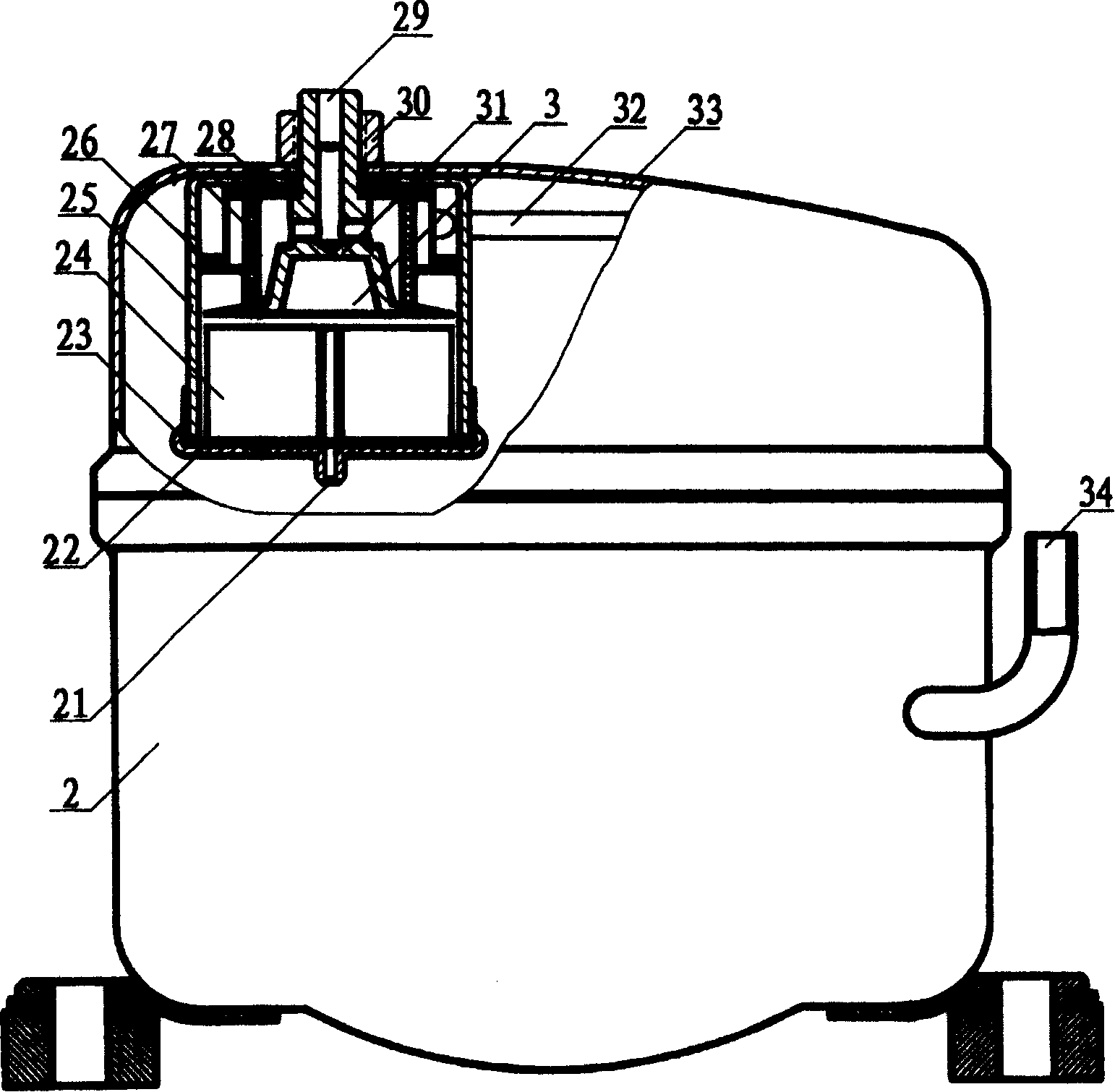

[0014] as attached image 3 The shown high-temperature oil separator 3 can be directly arranged in the housing 33 of the air compressor 2, the intake air 34 on the air compressor 2 is connected with the intake filter 1, the air outlet 29 is connected with the cooler 4, and the air The compressed air outlet 32 of the compressor is connected to the cylinder wall of the cylinder 25, the water baffle 31 is installed in the cylinder 25, the upper air outlet 29 protrudes from the top of the cylinder 25 and uses the nut 30 to connect the cylinder 25 and the casing 33 Fastened together with the water retaining plate 31, the filter element 27 is set on the outer edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com