Pre-coated sand, preparation method thereof and composite water permeable brick

A pre-coating and sand technology is applied in the field of pre-coated sand and its preparation, which can solve the problems of low strength, easy clogging of gaps, water-tightness, high cost, and achieve the effects of simple molding process, good water permeability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the pre-coated sand provided by the present invention comprises: heating the natural sand to 200-250°C, and then lowering the temperature; when the temperature drops to 190±10°C, adding coupling agent and pre-coated resin under stirring, stirring The time is 60±20 seconds, so that the pre-coated resin and coupling agent are coated on the natural sand; when the pigment is needed, add the pigment at this time and stir for 30±10 seconds; add the curing agent and stir; when the material When it is about to agglomerate, add lubricant and continue stirring until the material is completely dispersed; cool the material to ambient temperature.

[0020] The composite permeable brick provided by the present invention includes a sand-based surface layer and a concrete bottom layer; the sand-based surface layer includes pre-coated sand and fabric adhesive, and the pre-coated sand is the pre-coated sand provided by the present invention, so The concrete bott...

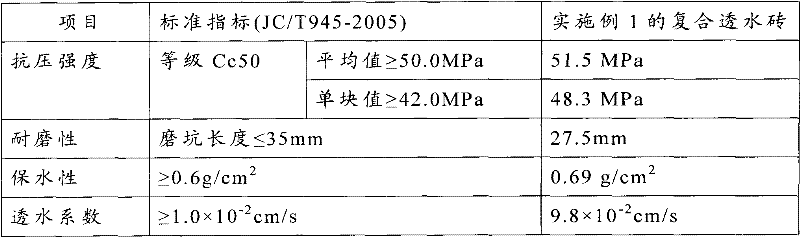

Embodiment 1

[0034] 1. Preparation of pre-coated sand

[0035] Heat 200kg of aeolian sand (particle diameter 0.425-0.212mm) to 210°C and pour it into the FS1612 sand mixer (Qingdao Wuyang Casting Machinery Co., Ltd.), and add hydrogenated bisphenol A epoxy when cooling to 190°C Resin (brand name: AL-3040, Yantai Olive Chemical Co., Ltd.) 1 kg and γ-glycidyl ether propyl trimethoxysilane 10 g stirred for 40 seconds; added iron oxide red 500 g stirred for 30 seconds; added modified fat Cyclic polyamine curing agent A (isophorone diamine, neopentyl glycol diglycidyl ether and acrylonitrile molar ratio is 1: 0.3: 0.4) 150 grams of stirring, when the material starts to agglomerate, add 100 grams of hard Calcium fatty acid is stirred and solidified for 180 seconds, cooled and sieved to obtain pre-coated aeolian sand.

[0036] 2. Preparation of permeable bricks

[0037] (1) Fabric ingredients:

[0038] Weigh 50 kilograms of the red pre-coated aeolian sand prepared above and put it into a QXH-1...

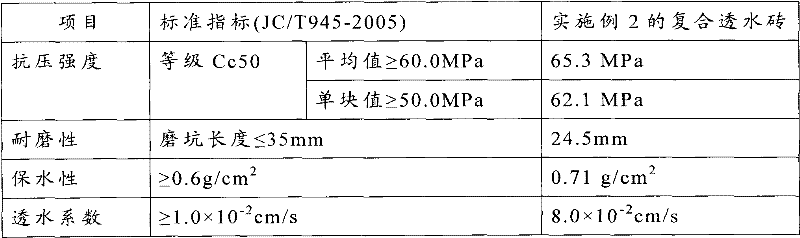

Embodiment 2

[0045] 1. Preparation of pre-coated sand for coloring treatment

[0046] In addition to changing the hydrogenated bisphenol A epoxy resin in Example 1 to 2 kilograms, changing γ-glycidyl ether propyl trimethoxysilane to 20 grams, and changing the modified alicyclic polyamine curing agent to 300 gram, and before adding the modified alicyclic polyamine curing agent, add 500 grams of iron oxide red and stir for 30 seconds, prepare red pre-coated aeolian sand according to the same method as in Example 1.

[0047] 2. Preparation of permeable bricks

[0048] (1) Fabric ingredients:

[0049] Weigh 50 kg of the red pre-coated aeolian sand prepared above and put it into the mixer for stirring; weigh the adhesive containing 2.7 kg of QXEP-1 resin and 0.8 kg of QXEPG-1 curing agent and put them together and stir evenly , add to the mixer equipped with pre-coated aeolian sand and continue to stir, and stop stirring after the adhesive and red pre-coated aeolian sand are stirred evenly. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com