Weaving equipment for weaving woolen blanket and the like

A technology for equipment and blankets, applied in the field of blanket weaving equipment, can solve the problems of economic loss, downgrade of blankets, small color spots, discoloration, etc., and achieve the effect of improving grade, excellent thermal insulation performance, and improving luxury and aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

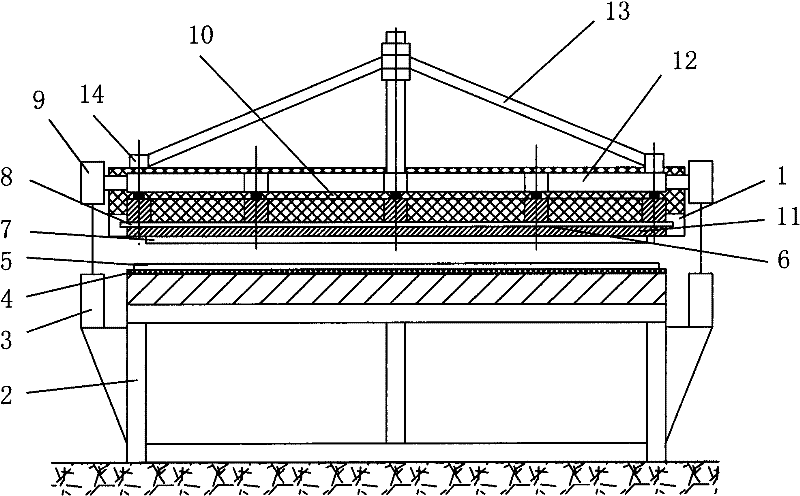

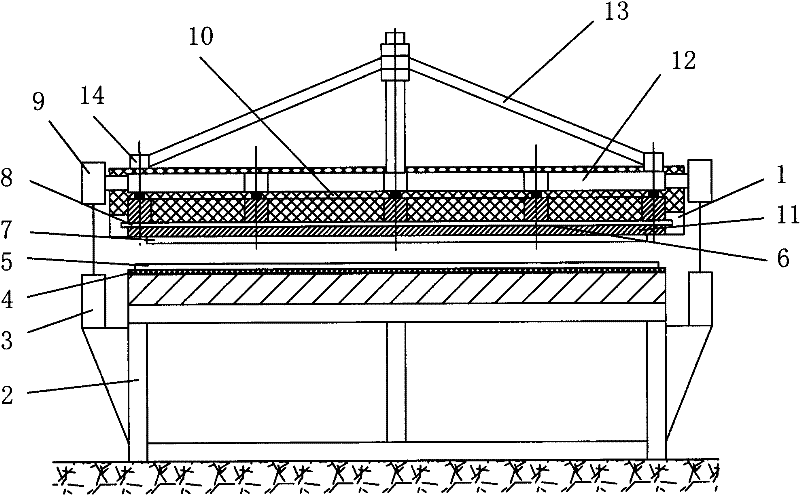

[0015] from figure 1 It can be seen in the figure that a kind of blanket-type weaving equipment is made by casting the upper frame and the lower frame, and four oil cylinders are installed on both sides of the upper frame and the lower frame to connect each other, and a panel is installed on the lower frame; Install the large plate, design three reinforcing ribs on the upper frame, install molds of different specifications under the large plate, install electric heating tubes inside the large plate, and set a layer of insulation layer above the electric heating tubes; There is a first layer of reinforcing ribs, a second layer of reinforcing ribs is provided in the insulation layer, the first layer of reinforcing ribs is fixedly connected with the second layer of reinforcing ribs, the second layer of reinforcing ribs is provided with upwardly protruding support rods and two There is a fixed block, the third layer of reinforcing rib is movably connected with the support rod and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com