Automatic sprinkling device of tire roller

A tire roller and sprinkler technology, applied in roads, roads, road repairs, etc., can solve the problems of wasting water, easy-to-stick asphalt materials, and water pump flow cannot be adjusted, and achieve the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

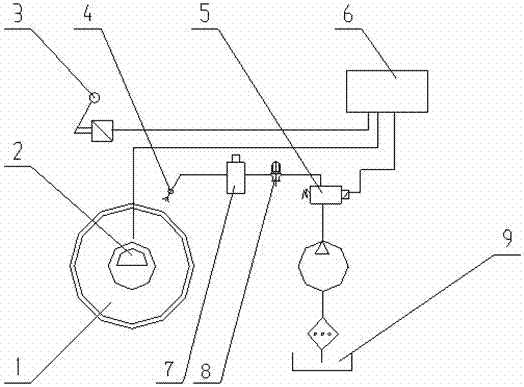

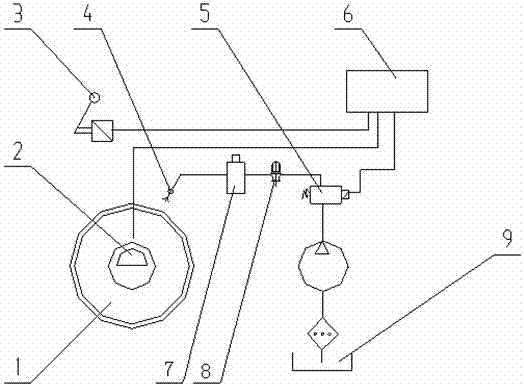

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] Such as figure 1 As shown, an automatic sprinkler device for a tire roller includes a driving handle 3, a spray device 4, a water pump 7, a filter 8 and a water tank 9, the spray device 4 is connected to the water pump 7, the water pump 7 is connected to the filter 8, and the filter 8 It is connected to the water tank 9 through a pipeline, and also includes a speed sensor 2 and a controller 6, the speed sensor 2 is installed on the wheel 1, the speed sensor 2 is electrically connected to the controller 6, the driving handle 3 is electrically connected to the controller 6, and a shut-off valve is also included 5. The shut-off valve 5 is installed between the filter 8 and the water tank 9.

[0012] The speed sensor 2 is installed on the wheel 1, and the speed sensor 2 detects the rotation speed of the wheel 1, and transmits the detected rotation speed signal of the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com