Metal wrapped-type high-temperature sealing structure and manufacturing method thereof

A technology of high-temperature sealing and manufacturing method, which is applied in the directions of sealing/isolation, earth-moving drilling, wellbore/well components, etc. Effects of reduced heat loss, avoided setting tonnage, and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

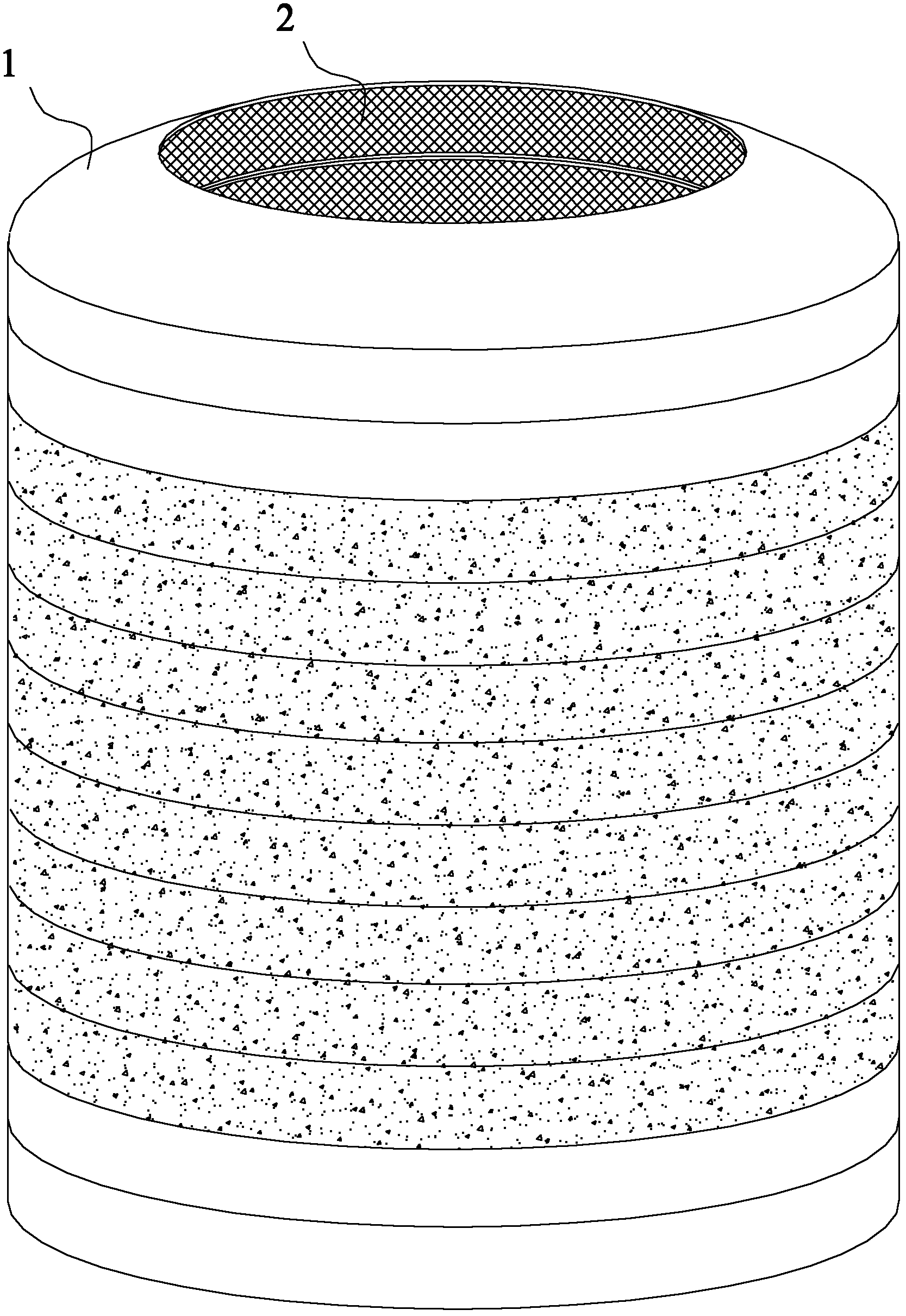

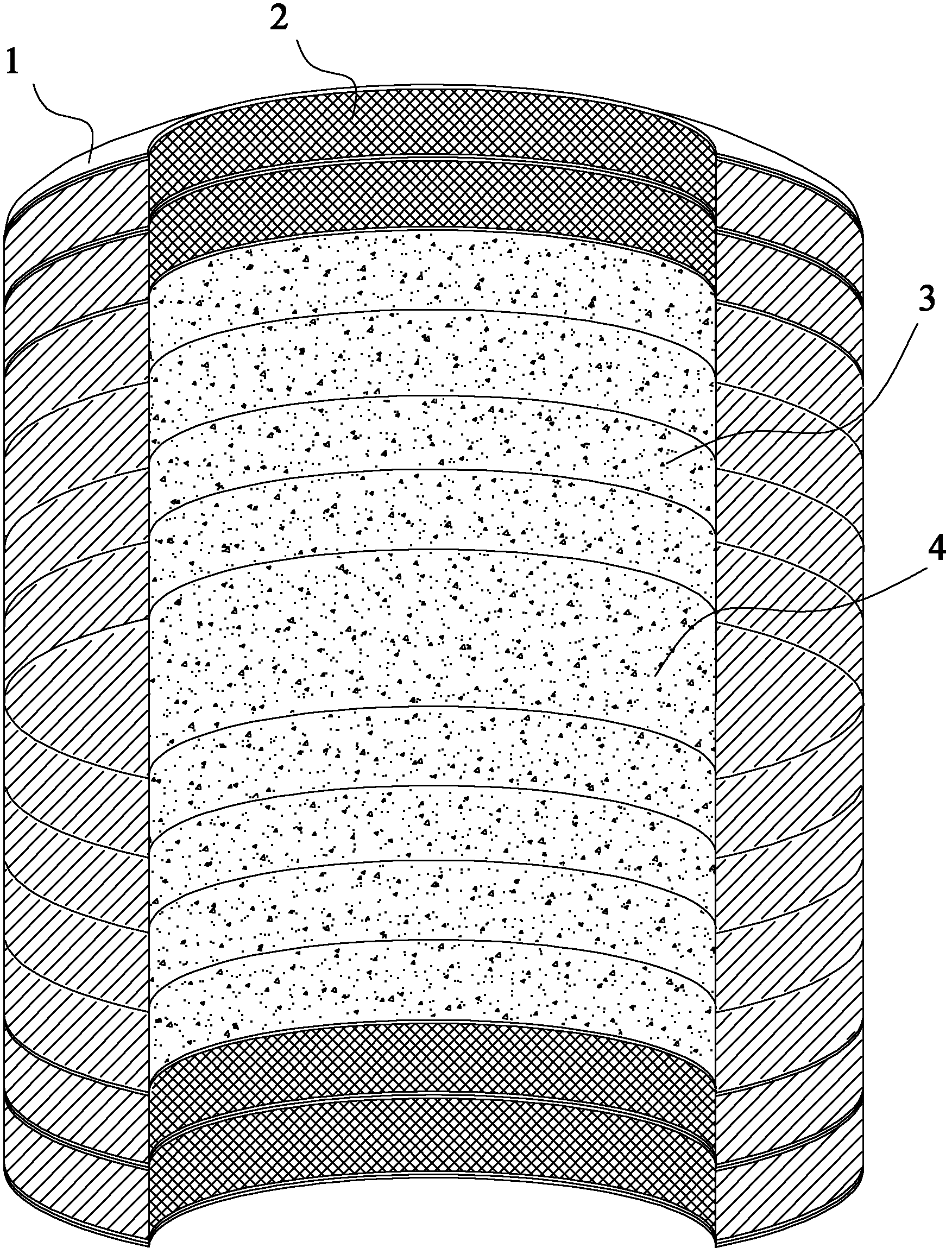

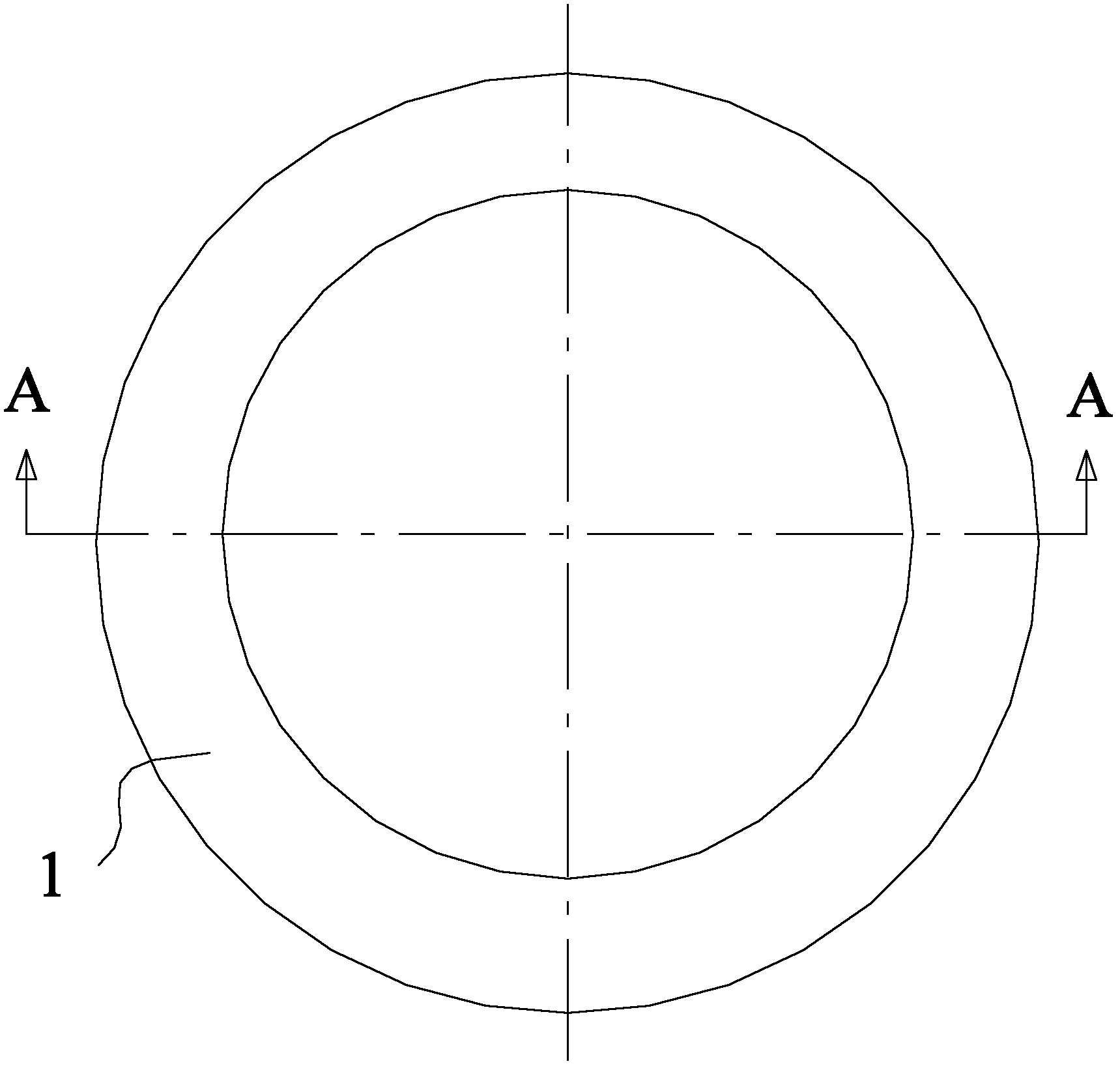

[0026] A metal-wrapped high-temperature sealing structure of the present invention is composed of at least two metal-wrapped protective structures and a sealing member arranged between the metal-wrapped protective structures, and the metal-wrapped protective structure includes a metal-wrapped protective structure layer and an inner filling ring; the metal wrapping layer forms a metal bowl-shaped collar, the metal bowl-shaped collar has an inward opening, the metal wrapping layer wraps the inner filling ring, and the metal wrapping protective structure can prevent Both sides of the sealing member are raised, and are resistant to friction and water erosion.

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0028] Please refer to Figure 1 to Figure 4 Shown is a three-dimensiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com