Vibration damping system capable of being quickly expanded

A vibration damping system, fast technology, applied in the direction of non-rotational vibration suppression, etc., can solve problems such as non-conformity, complicated vibration damping devices, etc., and achieve the effect of small size, compact structure layout, and convenient and quick mutual conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

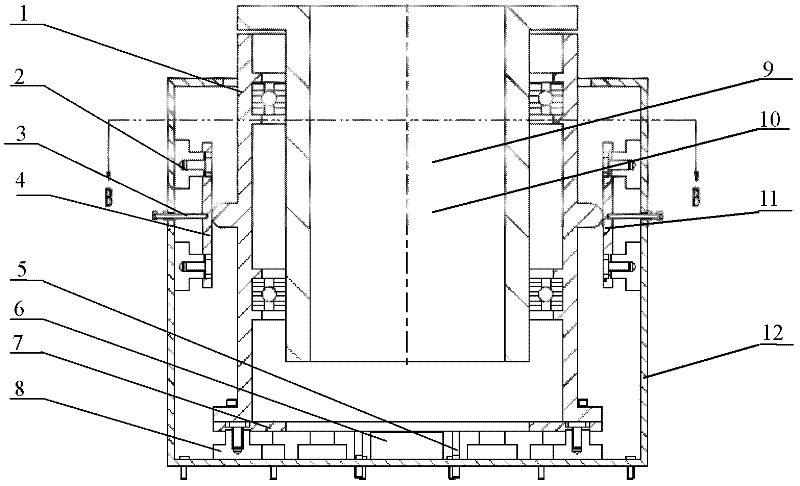

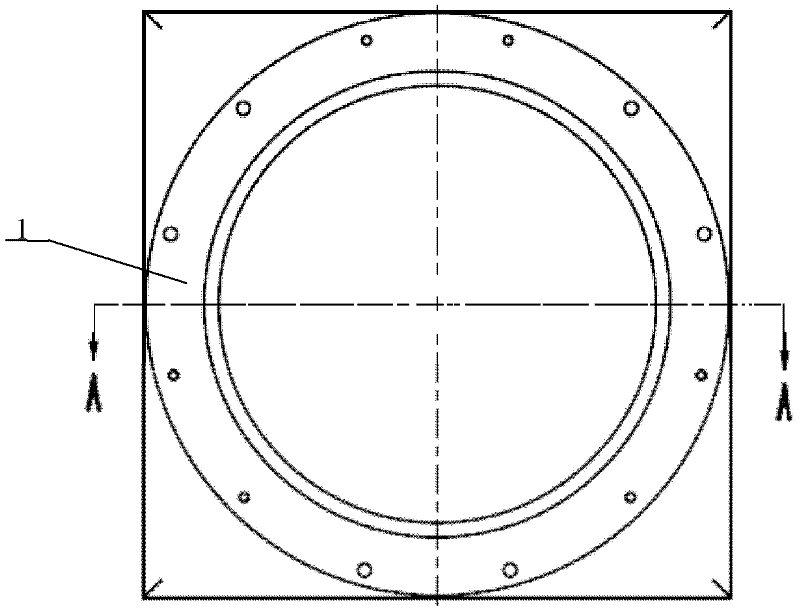

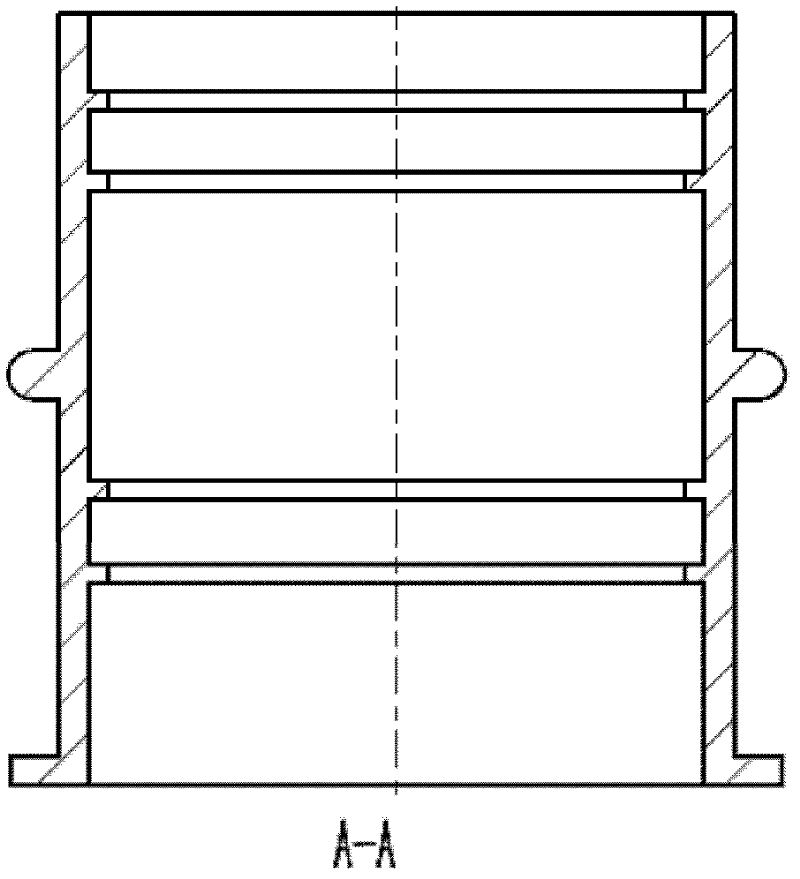

[0026] Such as figure 1 As shown, the rapid deployment damping system of the present invention consists of a base 1, a side vibration isolator 2, a preload screw 3, a left baffle 4, a compression bolt 5, a support block 6, a bottom baffle 7, a bottom partition vibrator 8, rear baffle 9, front baffle 10, right baffle 11, box 12; the box 12 is fixed on the platform by screws, and the left baffle 4, right baffle 11, front The baffle 10 and the rear baffle 9 are connected with multiple side vibration isolators 2 (the number of side vibration isolators connected to each baffle is related to the movement environment of the platform, the weight and specific structure of the photoelectric tracking and measuring equipment , is also related to the specific parameters of the selected or designed vibration isolators, and the number can only be determined for specific task requirements. In the present invention, the number of side vibration isolators connected to each baffle is six and abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com