Driving device for pipe reducing device

A driving device and pipe shrinking technology, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of liquid leakage, danger, inconvenient, etc., and achieve narrow pipe opening, strong mechanization, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

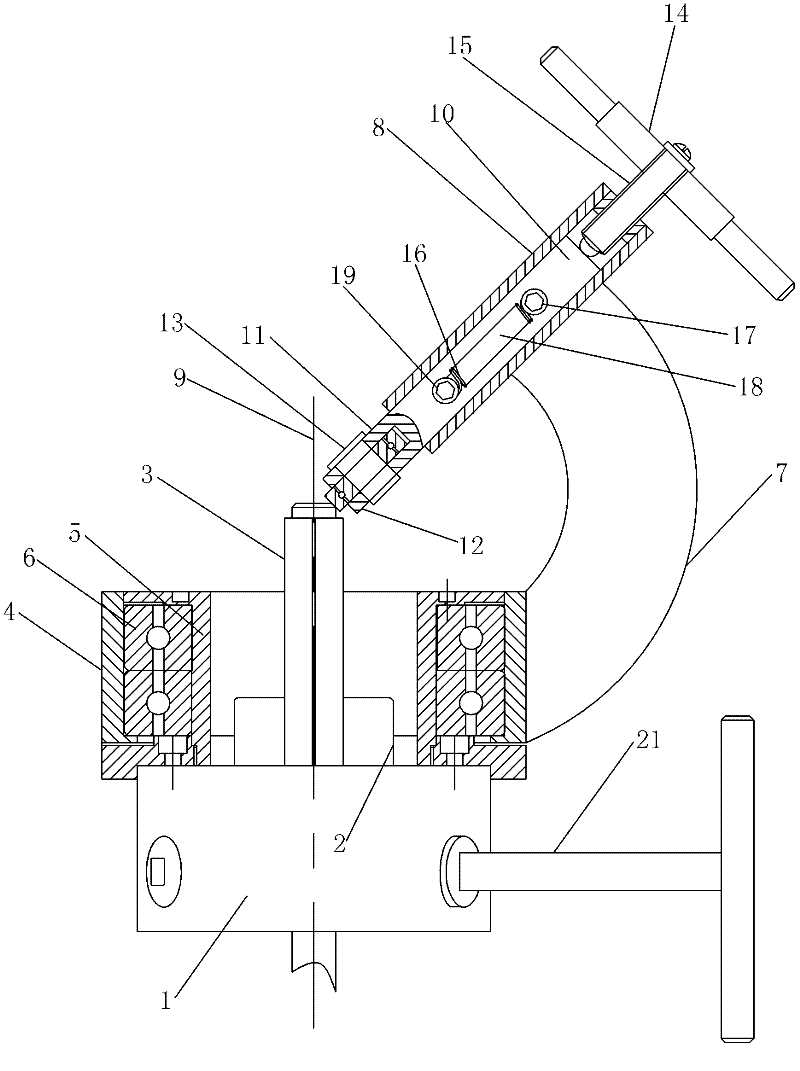

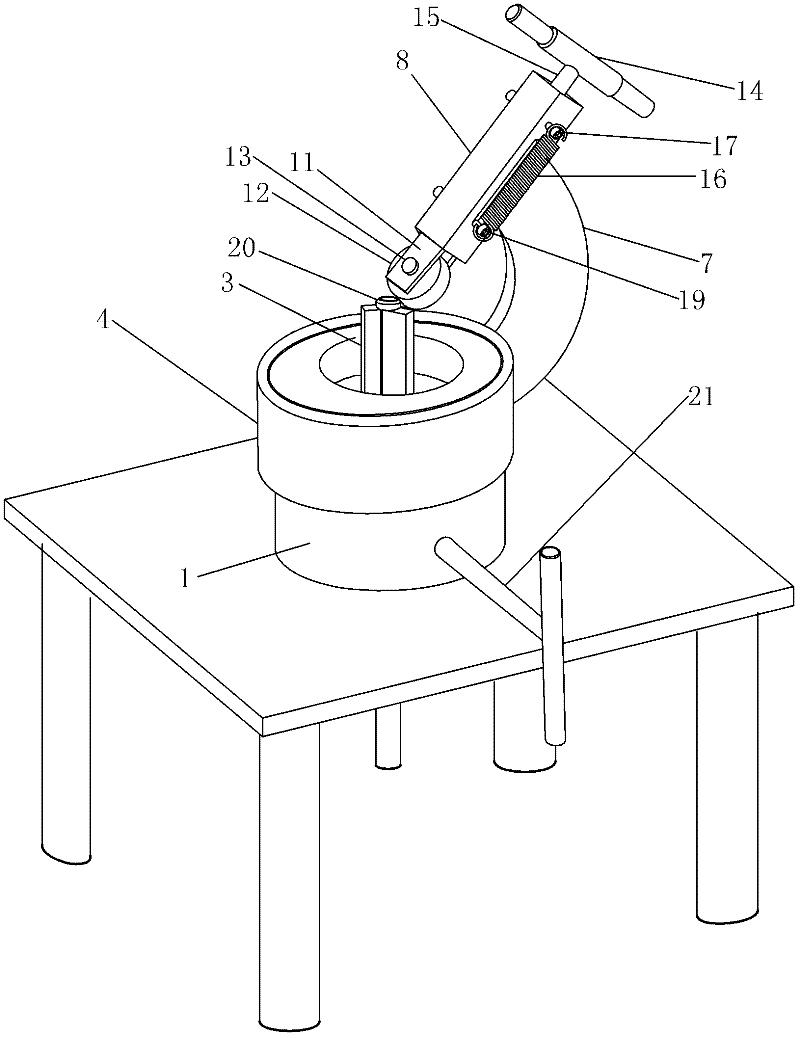

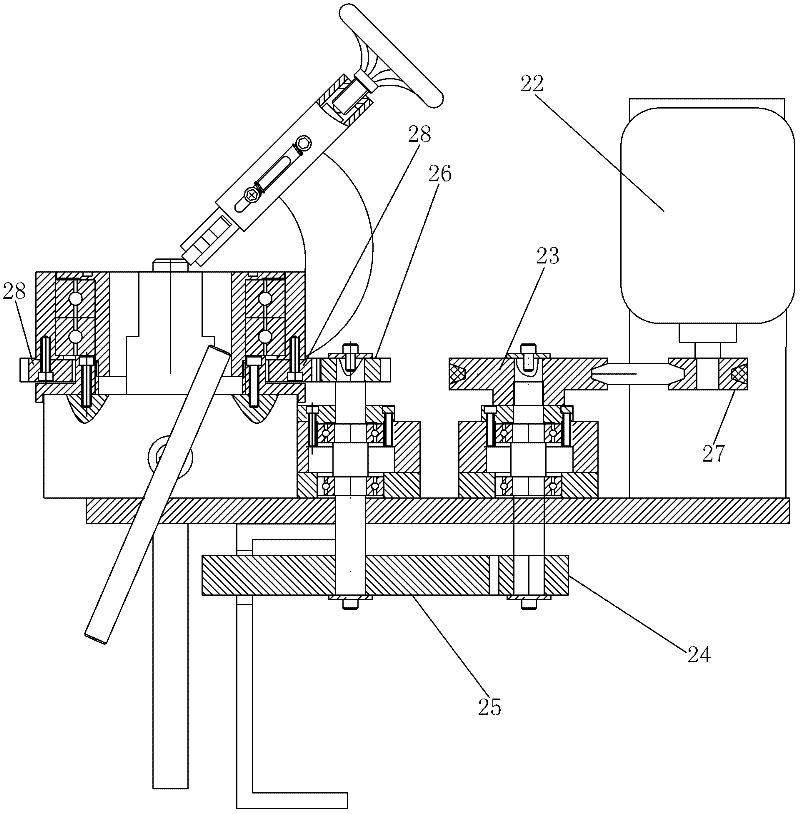

[0013] Example: such as Figure 1 ~ Figure 2 As shown, a semi-automatic tube shrinking device includes a clamping assembly for clamping the tube and a shrinking assembly for changing the size of the nozzle. The clamping assembly becomes a three-jaw chuck, and a three-jaw chuck It includes a fixed seat 1. Three claws 2 are provided on the fixed seat 1. Each claw 2 is provided with a clamping foot 3 that moves with the claw and clamps the pipe. The clamping foot 3 and the claw 2 are clamped The clamping foot 3 is 5 cm long.

[0014] The necking assembly includes two sleeves inside and outside. The outer sleeve 4 is sleeved outside the inner sleeve 5. The inner sleeve 5 is fixed on the fixed seat 1. A bearing 6 is arranged between the inner and outer sleeves. The inner ring and the outer ring of 6 are respectively connected to the inner sleeve 5 and the outer sleeve 4. The outer sleeve 4 rotates around the longitudinal central axis 9 of the fixing seat 1 of the clamping assembly, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com