Semiautomatic pipe reducing device

A semi-automatic, driving device technology, applied in the field of nozzle processing, can solve problems such as danger, liquid leakage, welding inconvenience, etc., and achieve the effects of reducing labor intensity, reducing nozzle size, and increasing the degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

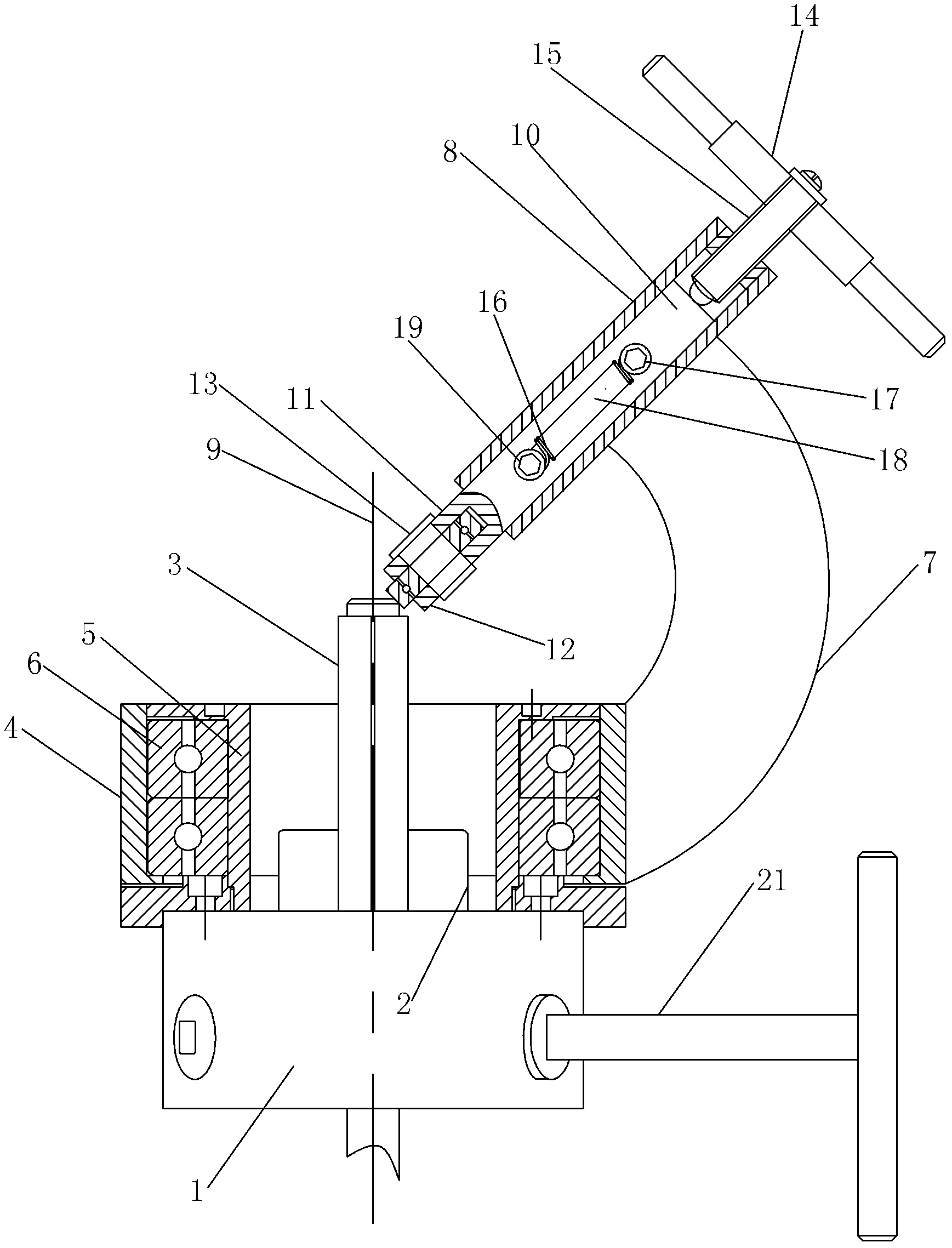

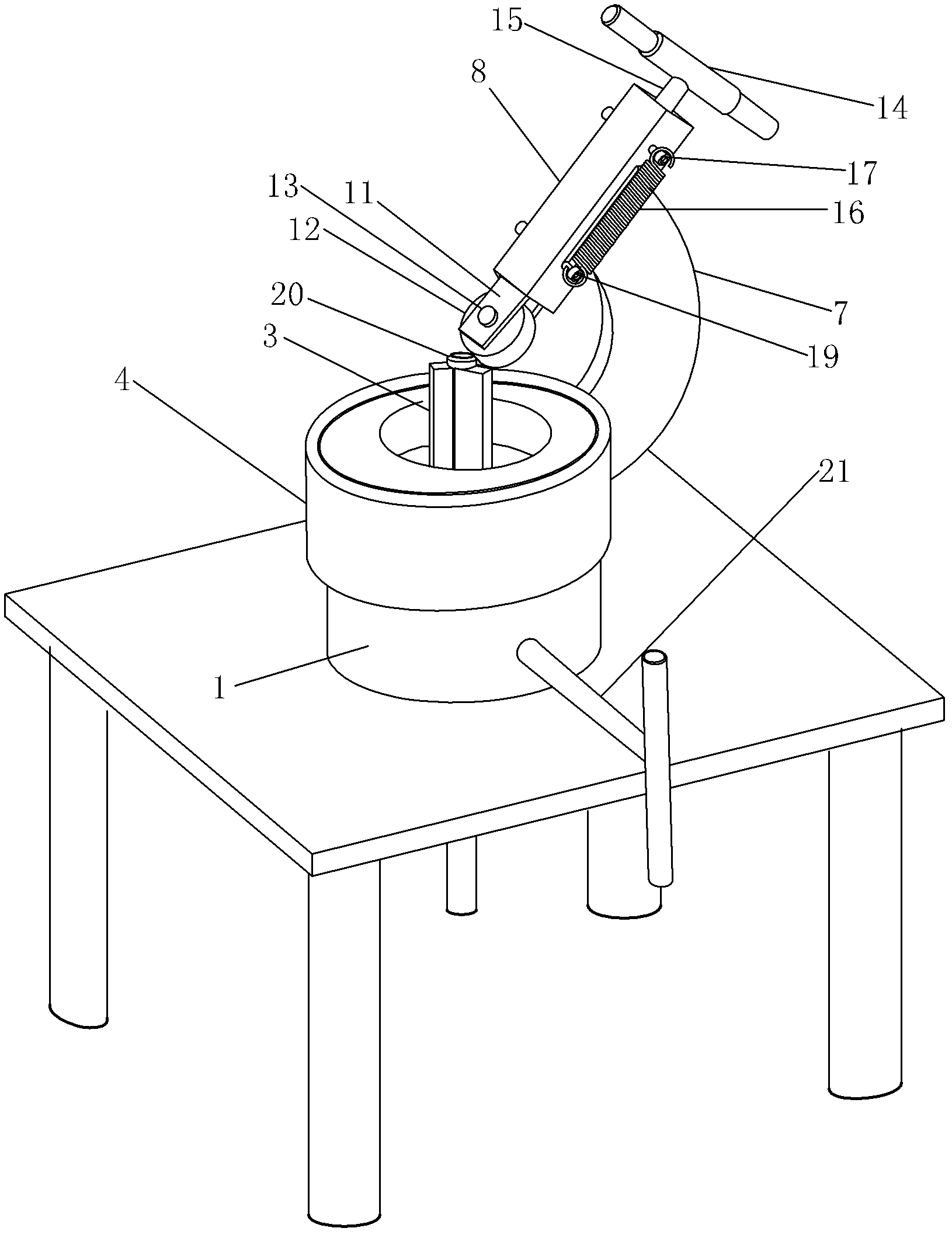

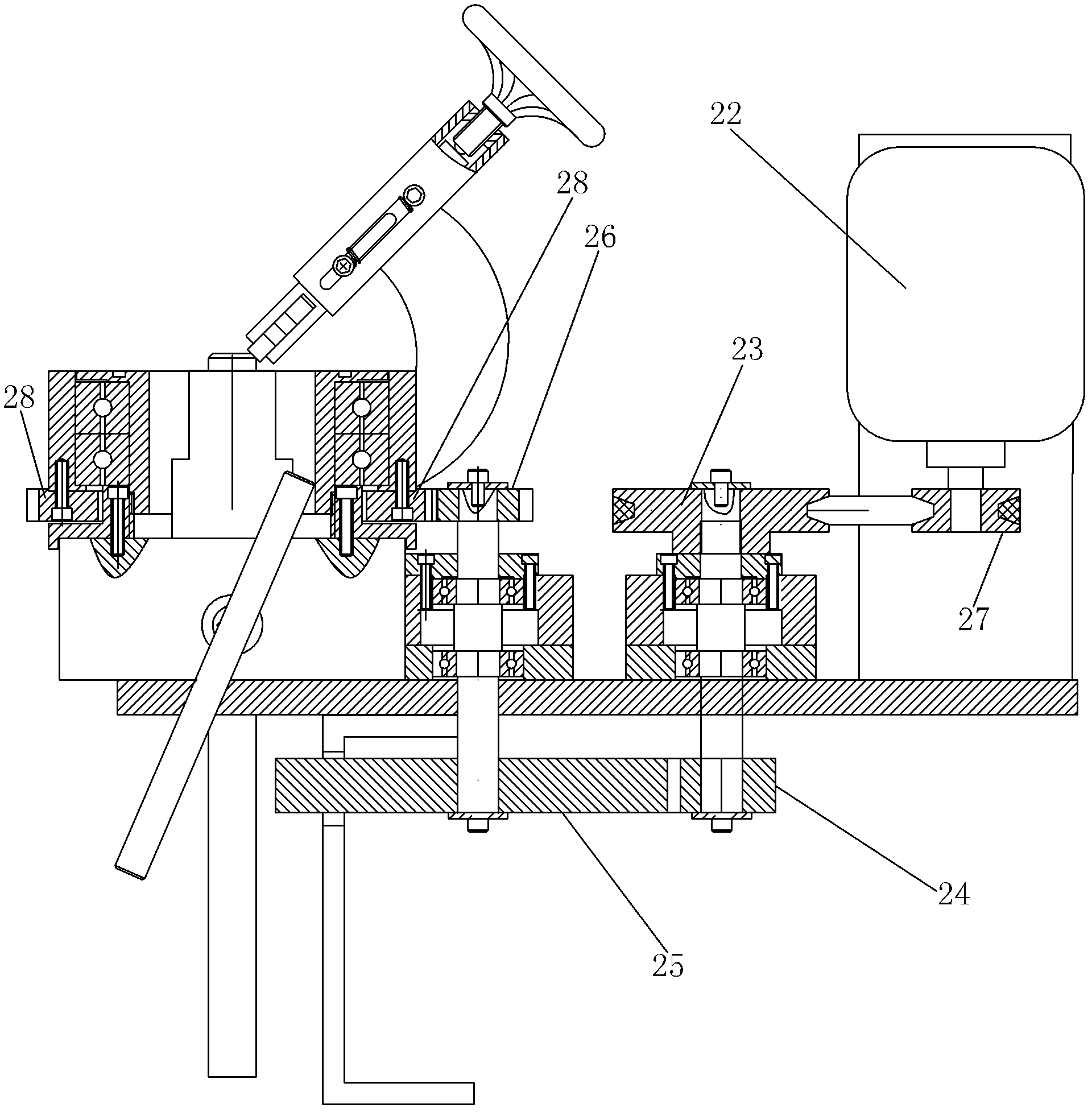

[0019] Example: such as Figure 1 ~ Figure 2 As shown, a semi-automatic shrinking device includes a clamping assembly for clamping the pipe and a shrinking assembly for changing the size of the nozzle. The clamping assembly is a three-jaw chuck, and the three-jaw chuck It includes a fixed base 1, on which there are three claw bodies 2, and each claw body 2 is provided with a clamping foot 3 that moves with the claw body and clamps the pipe, and the clamping foot 3 and the claw body 2 adopt a clamp Connecting way, thereby can convenient loading and unloading, the length of described clamping foot 3 is 5cm.

[0020] The necking assembly includes two inner and outer sleeves, the outer sleeve 4 is set outside the inner sleeve 5, the inner sleeve 5 is fixed on the fixed seat 1, and a bearing 6 is arranged between the inner and outer sleeves. The inner ring and the outer ring of 6 are respectively connected with the inner sleeve 5 and the outer sleeve 4, and the outer sleeve 4 rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com