Heat removal equipment of refrigeration system for mine

A refrigeration system and mine-used technology, which is applied in mining equipment, mine/tunnel ventilation, earthwork drilling and mining, etc. It can solve the problem of complex connection structure between heat exchange tubes and liquid distribution tubes, uneven distribution of refrigeration media, and problems with heat exchangers. Low thermal efficiency and other issues, to achieve the effect of ensuring heat exchange efficiency, improving heat removal capacity, and meeting heat removal needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the drawings and embodiments.

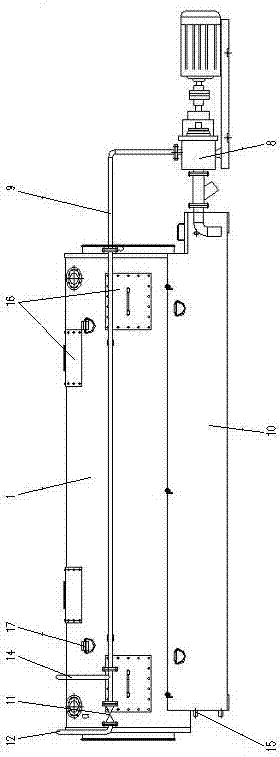

[0031] As shown in the figure, the heat rejection equipment of the mining refrigeration system of this embodiment includes a tubular heat exchanger shell 1 in which a heat exchange tube assembly and a cooling device sprayed to the heat exchange tube assembly are provided. Spray assembly, one end of the heat exchanger shell 1 is an air inlet end, and the other end is an air outlet end;

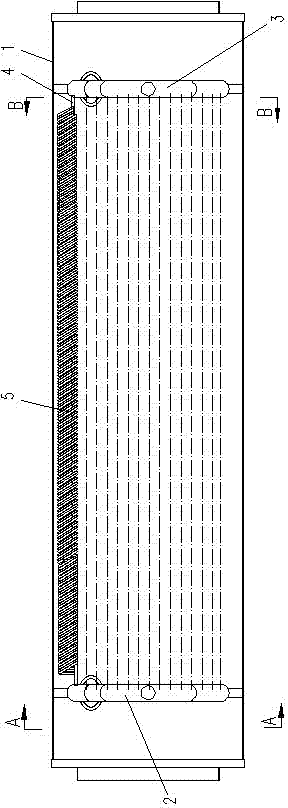

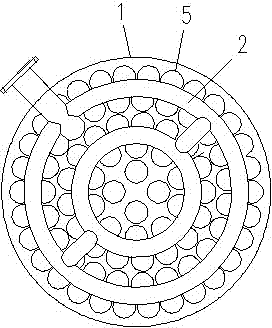

[0032] The air inlet end of the heat exchanger shell 1 is provided with a liquid collecting pipe 2, and the air outlet end of the heat exchanger shell 1 is provided with a liquid separator 3, and the heat exchange tube assembly includes a short branch pipe 4 and The four heat exchange tubes 5 whose ends are fixedly connected to the short split tube 4 (of course, in different embodiments, the number of heat exchange tubes 5 on the same short split tube 4 can also be two or more other values,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com