Expansion valve

An expansion valve and spool technology, applied in the field of expansion valves, can solve the problems of difficult welding process, complex mechanism, slow response time, etc., and achieve the effect of facilitating accurate flow control, realizing forward and reverse flow control, and system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

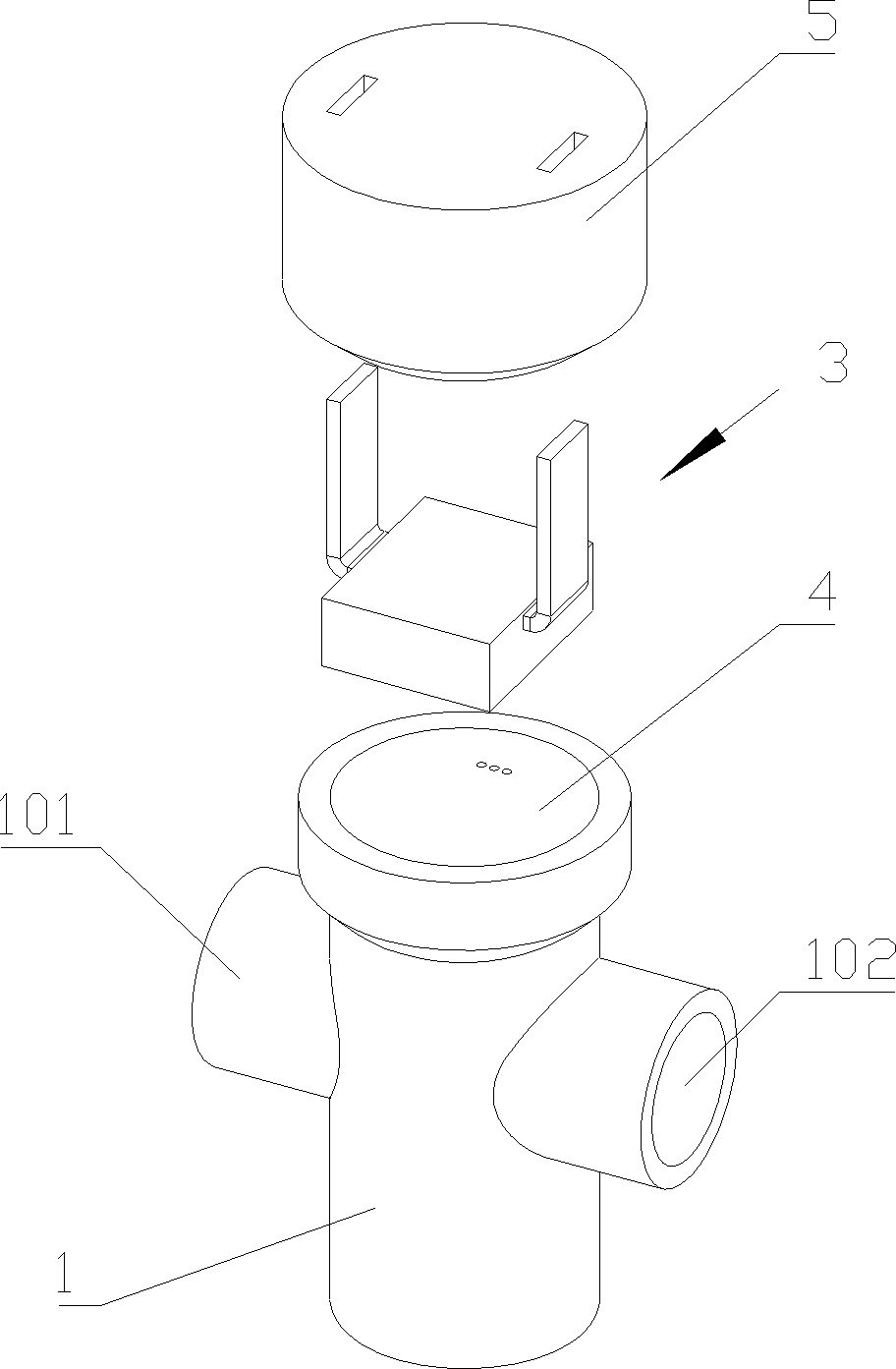

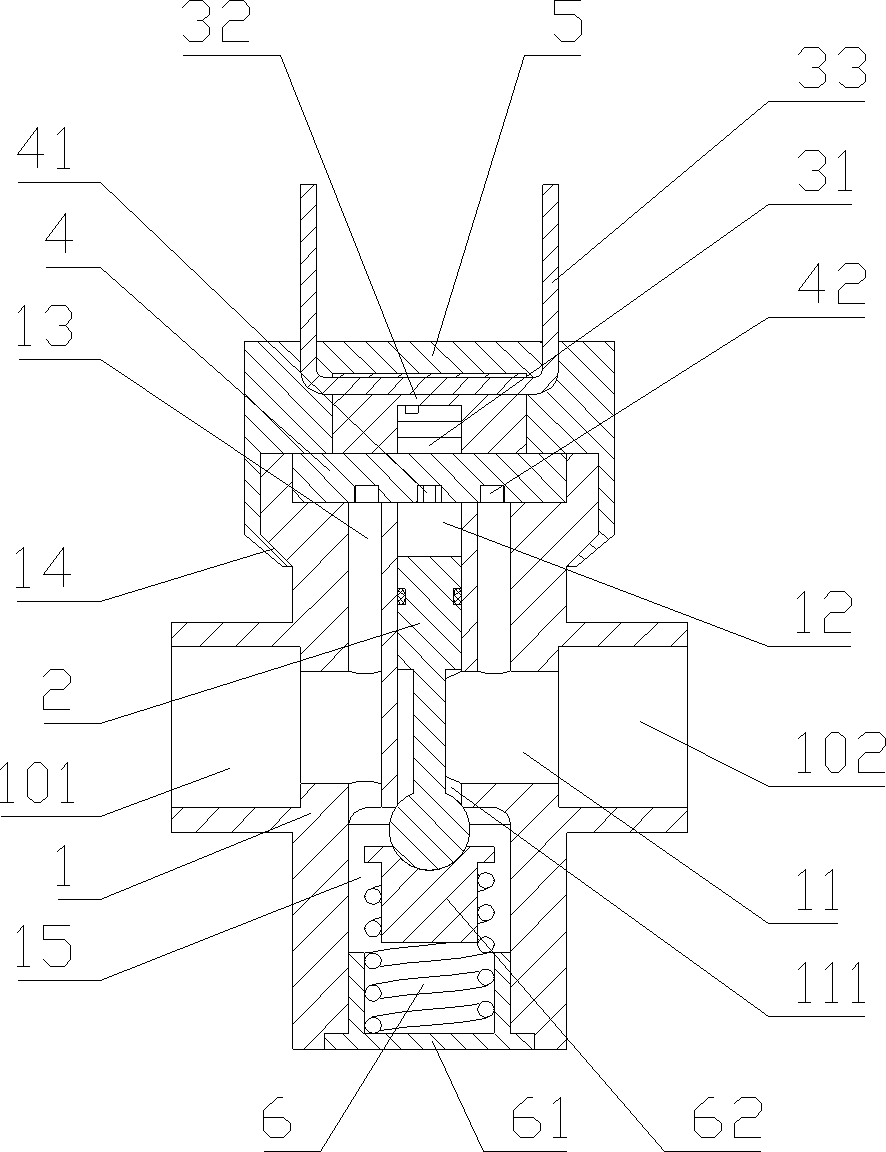

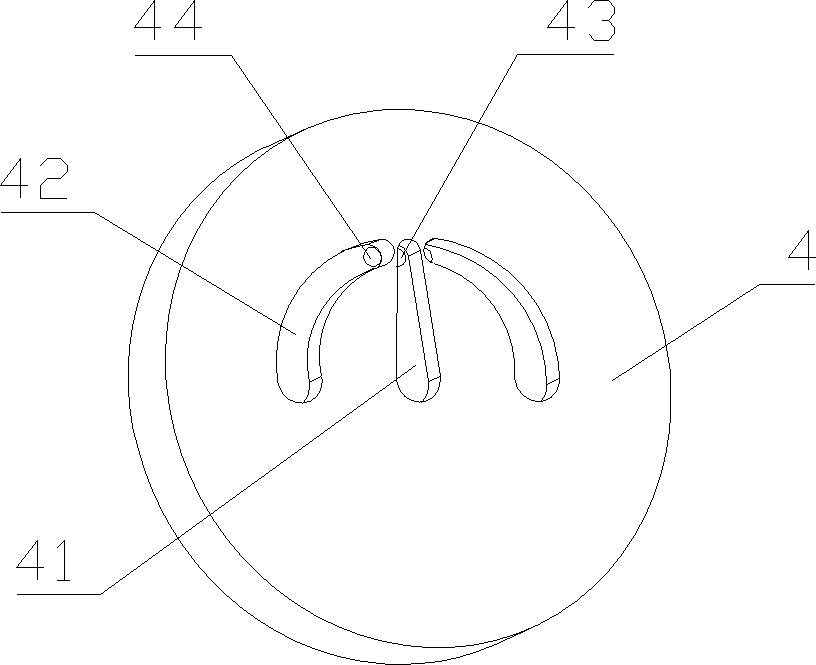

[0021] Such as Figure 1 to 5 Shown is a schematic structural view of an embodiment of the present invention. An expansion valve includes a valve body 1, a valve core 2 and a drive component 3. The valve body is transversely provided with a first flow passage 11 for refrigerant to circulate, and the first flow passage communicates with The inlet 101 and outlet 102 of the valve body are vertically provided with a main flow hole 12 above the first flow passage in the valve body, and a main flow port 111 is provided in the first flow passage corresponding to the main flow hole. The upper part of the valve core is set in the main flow hole to remove the main flow The hole is disconnected from the first flow channel, and the lower part of the valve core corresponds to the main flow port. The valve core moves up and down along the main flow hole to open or close the main flow port. A second flow parallel to the main flow hole is also provided in the valve body above the first flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com