Automatic clutch for car driving mechanism based on helicoid spring compensation

An automatic clutch and driving mechanism technology, applied in the direction of clutches, mechanical equipment, etc., can solve the problems of complex design process of telescopic spring compensation mechanism, driving mechanism connection, inconvenient layout, and poor compensation function, so as to facilitate quick start and connection form And the layout is convenient and simple, the effect of lightening the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

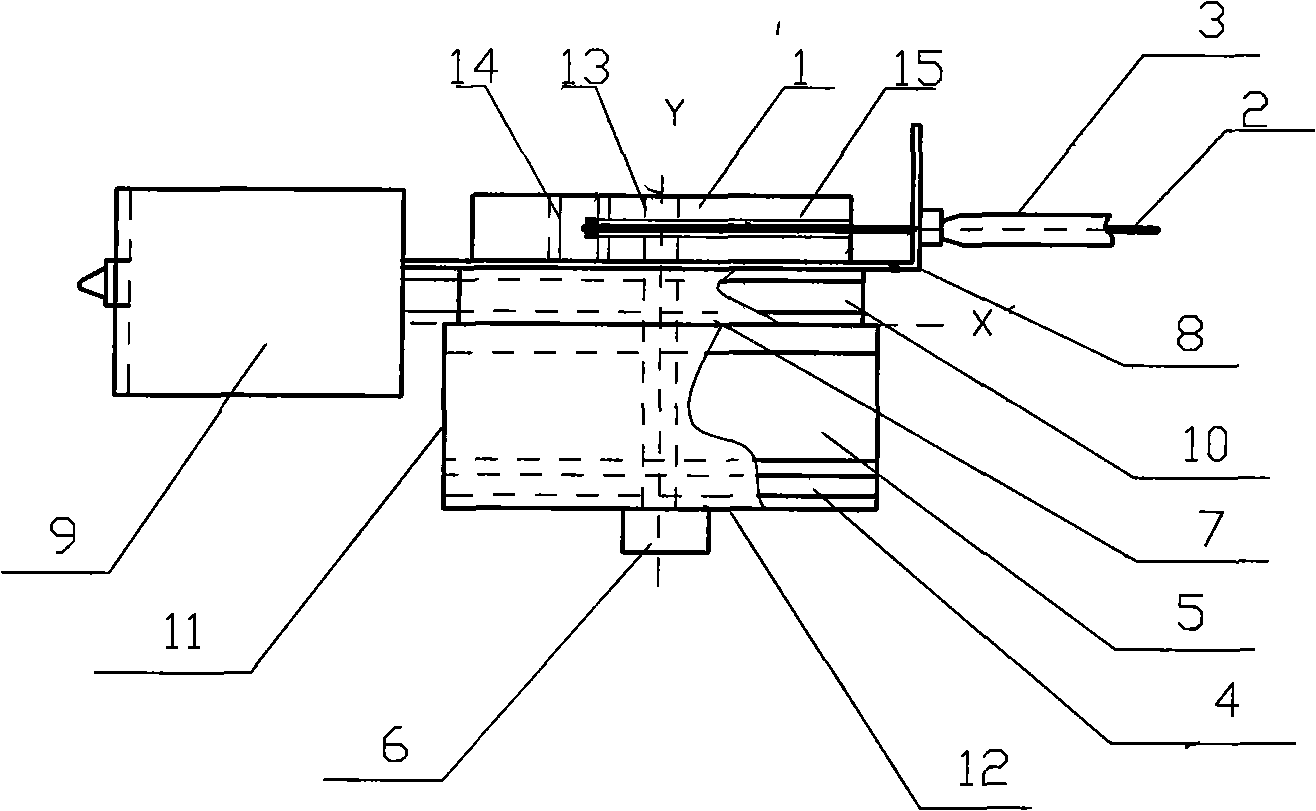

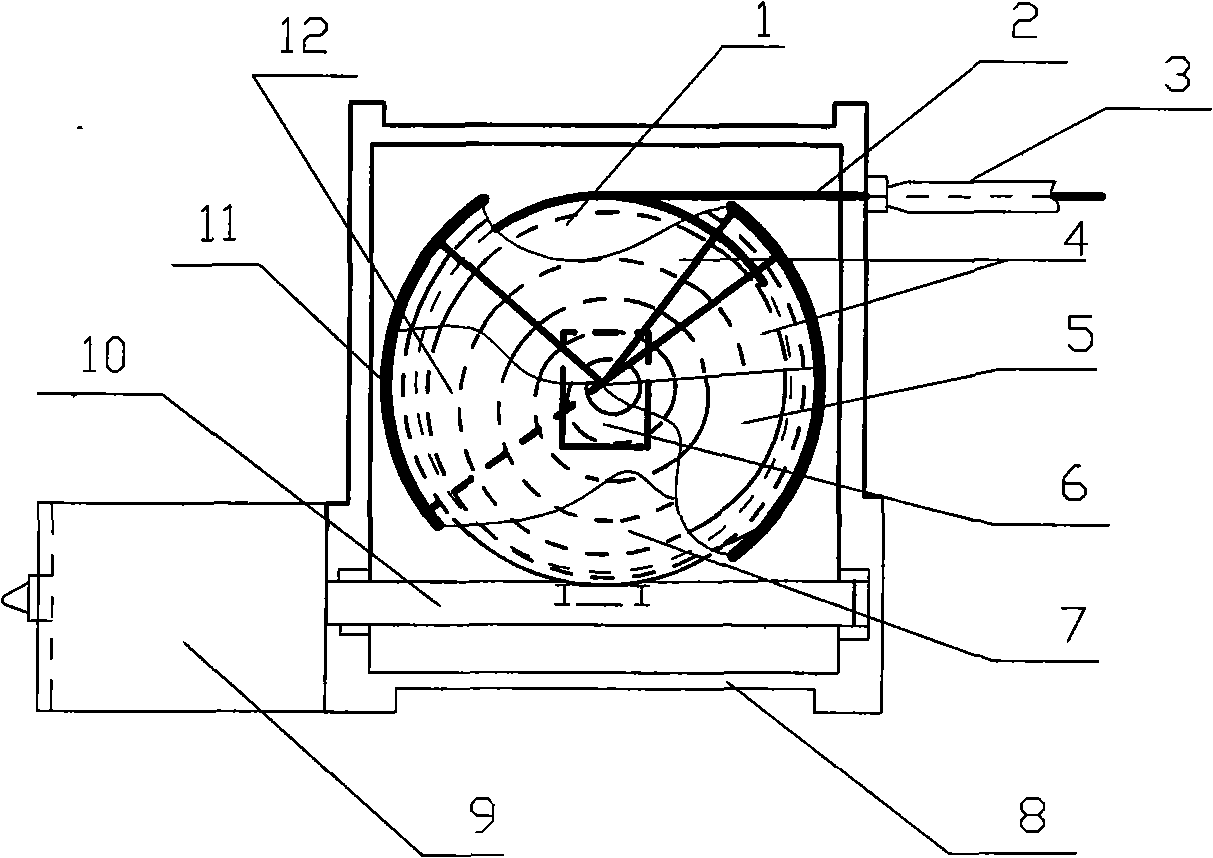

[0022] An automobile automatic clutch drive mechanism based on volute spring compensation, which consists of: a central drive shaft 13, a DC drive motor 9, a self-locking worm gear reduction mechanism, a volute compensation spring 5, a drive plate 1, a cylindrical cylinder 11, Mechanical limit mechanism 4, angle position sensor 6, clutch cable 2, support 8, described central drive shaft 13 is connected with self-locking type worm gear reduction mechanism through bearings at both ends on the housing, described central drive shaft 13 Connect with the inner end of the worm wheel 7, the driving disc 1 and the scroll compensation spring 5 respectively, the outer end of the scroll compensation spring 5 is connected with the cylinder 11, and the scroll compensation spring 5 is pre-prepared before installation. tight.

[0023] In the automobile automatic clutch drive mechanism based on scroll spring compensation, the cylinder 11 is connected to the mechanical limit mechanism 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com