Detection device for dimensions of flange thread hole and end surface of exhaust pipe

An exhaust pipe and flange technology is applied in the field of exhaust pipe flange wire holes and end face size inspection tools, which can solve the problems of missing detection pins, abrasion of detection pins, inaccurate detection, etc., so as to reduce manufacturing difficulty and prevent loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

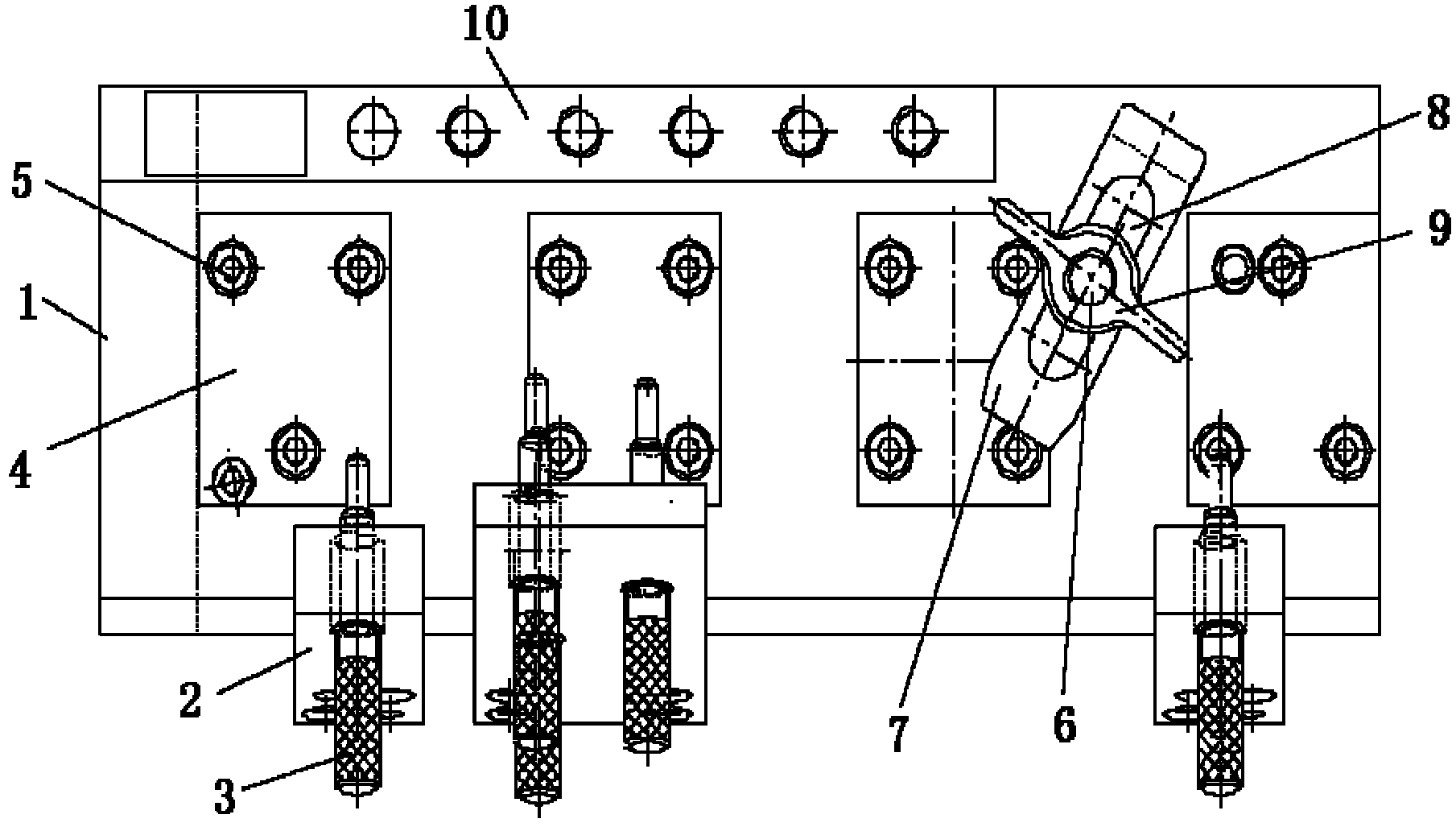

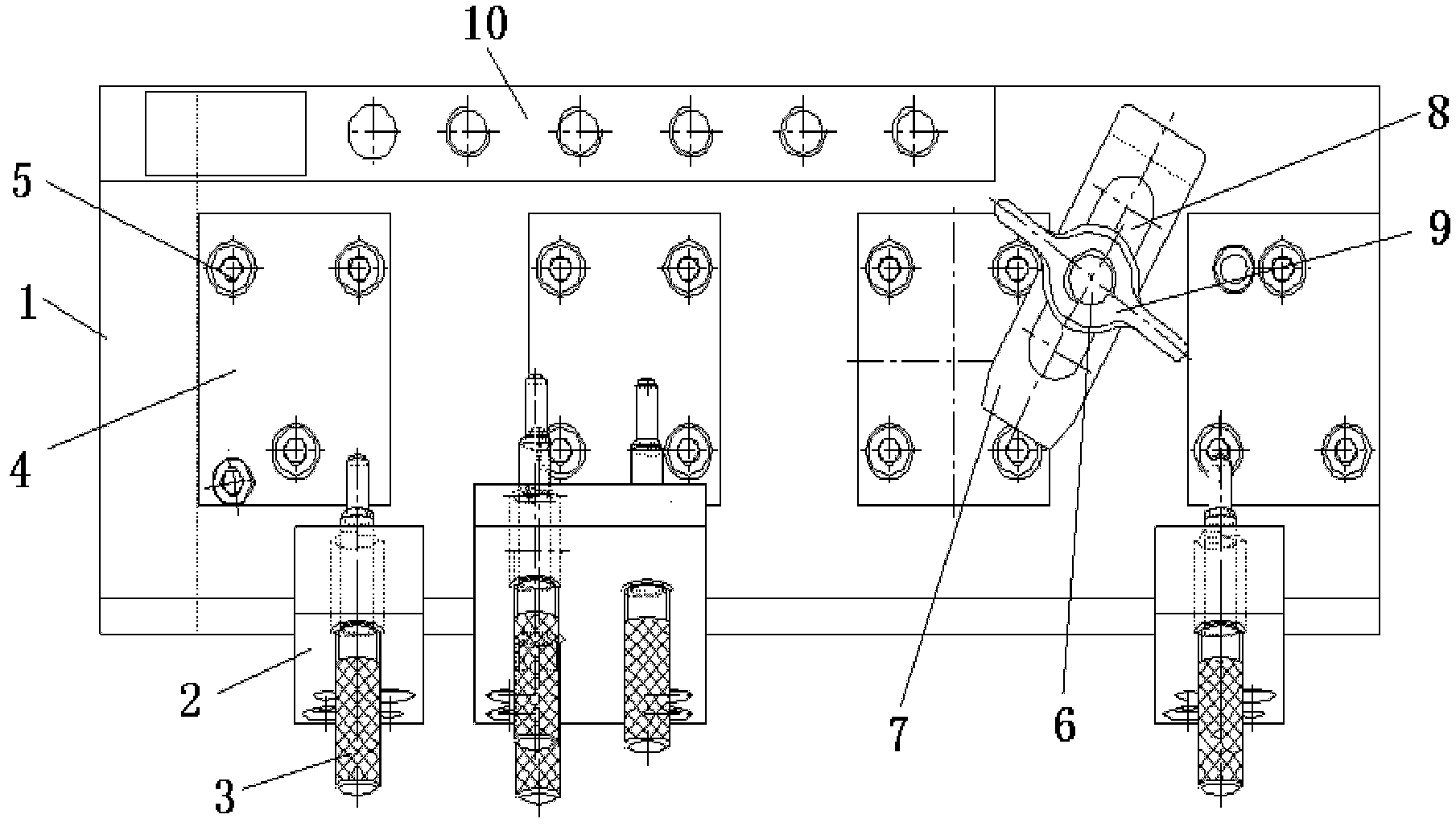

[0009] Referring to the accompanying drawings, an exhaust pipe flange thread hole and end face size inspection tool includes a bottom plate 1 and a detection plate 2. A plurality of detection plates 2 are arranged on the lower side of the bottom plate 1. On the detection plate 2 There are a plurality of detection pins 3, and the upper surface of the bottom plate 1 is provided with a plurality of pads 4, and a plurality of limit pins 5 are arranged on the pads 4, and a double-ended stud is fixedly installed on the right end of the bottom plate 1 6. The double-ended stud 6 is covered with a pressure plate 7, and the middle of the pressure plate 7 has a strip-shaped hole 8. The top of the double-ended stud 6 is fitted with a wing nut 9, and the pressure plate 7 passes through the disc-shaped The nut 9 adjusts the up and down position, and the upper end of the bottom plate 1 has a latch plate 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com