One-way valve rubber tube positive pressure opening and negative pressure leakage detection device and operation method

A technology of leak detection device and one-way valve, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., which can solve the problem that it is difficult to monitor whether the test result is correct or not, and the accuracy of the test result is difficult to guarantee. Problems such as poor operability in the detection process, to achieve the effect of improving detection accuracy, simple structure, and simple results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

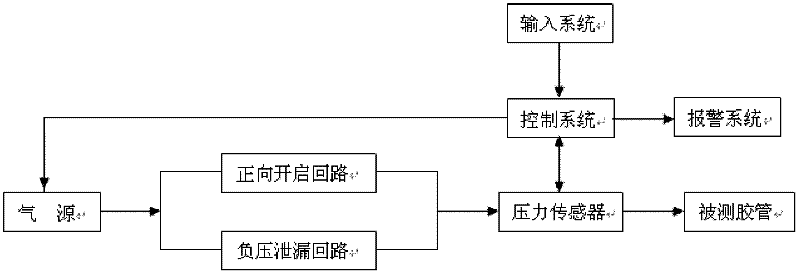

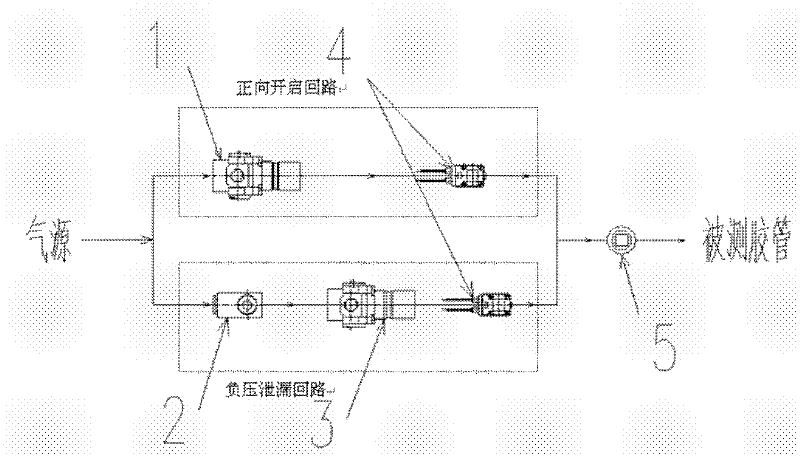

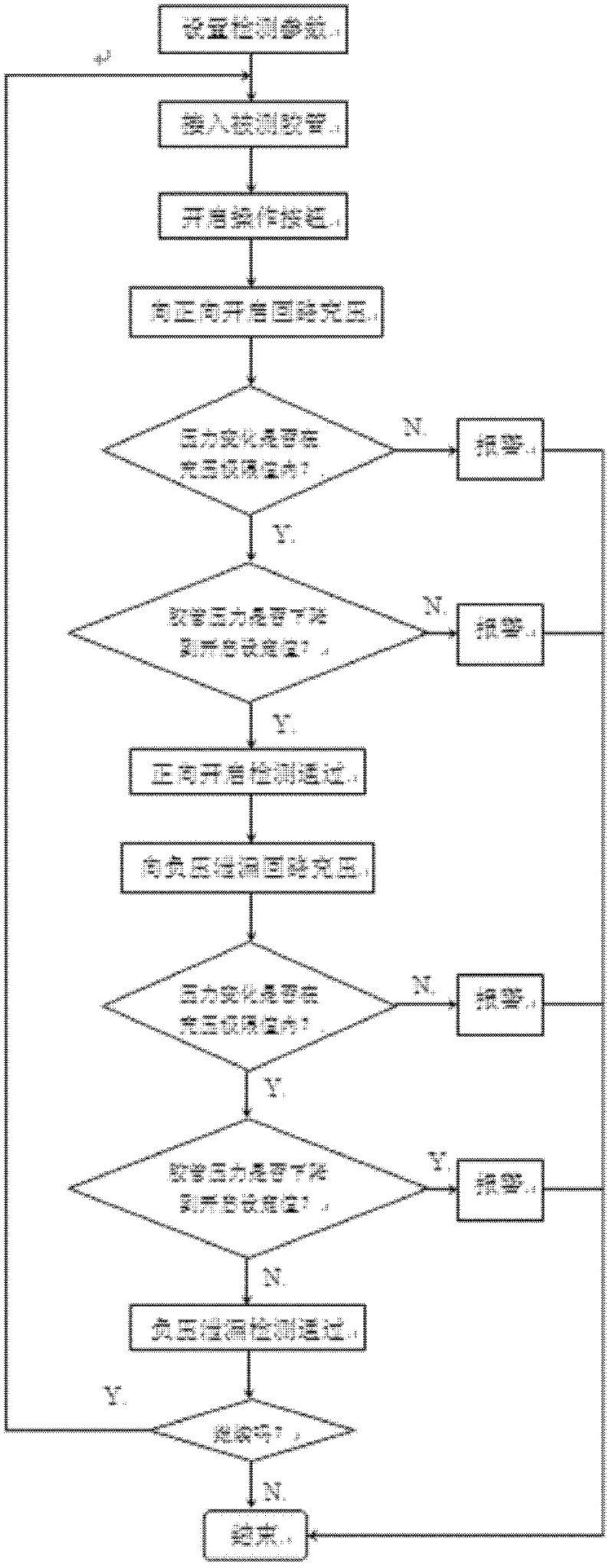

[0015] This embodiment is the positive pressure opening of the one-way valve rubber hose and the negative pressure leakage detection operation. The inspection process is as image 3 Shown: Before the detection starts, input the detection parameters of the positive pressure opening process from the touch screen of the man-machine interface: positive pressure charging pressure, charging limit value (to control the stability of the gas source), opening set value, opening time; and then input the negative pressure Pressure leakage process detection parameters: negative pressure filling pressure, filling limit value (to control the stability of gas source), pressure limit value, and pressure holding time.

[0016] First input the positive pressure opening and negative pressure leakage process detection parameters, connect the tested rubber hose to the pressure sensor in the forward direction, and block the other end. Turn on the operation button, and the check valve positive openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com