Measuring device and method of melting volume expansion ratio/molten state density of material

A technology of volume expansion and measuring device, which is used in the measurement of density of molten state, the measurement of thermal expansion coefficient of materials, and the solid-liquid phase transition of materials. , the device is simple, the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

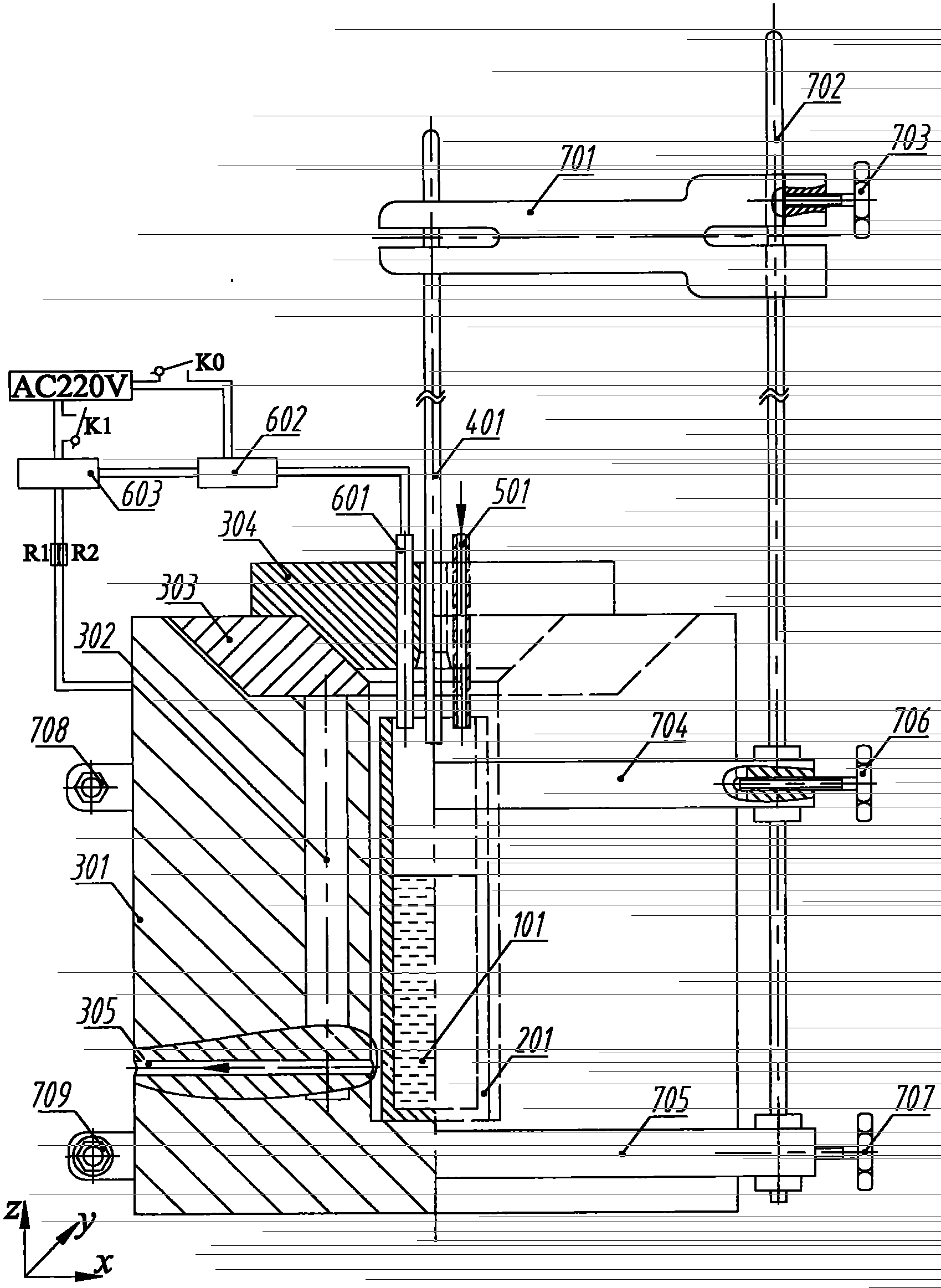

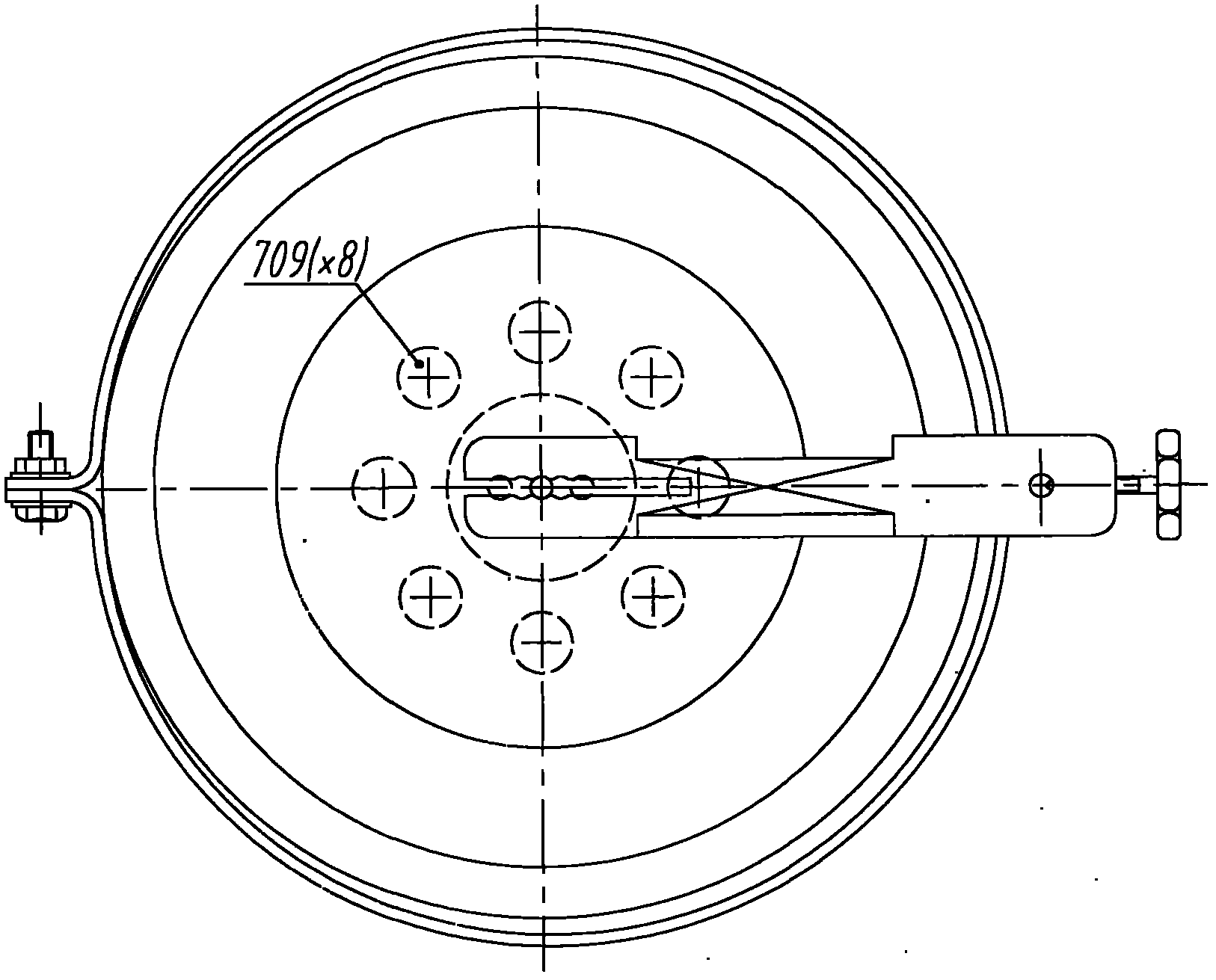

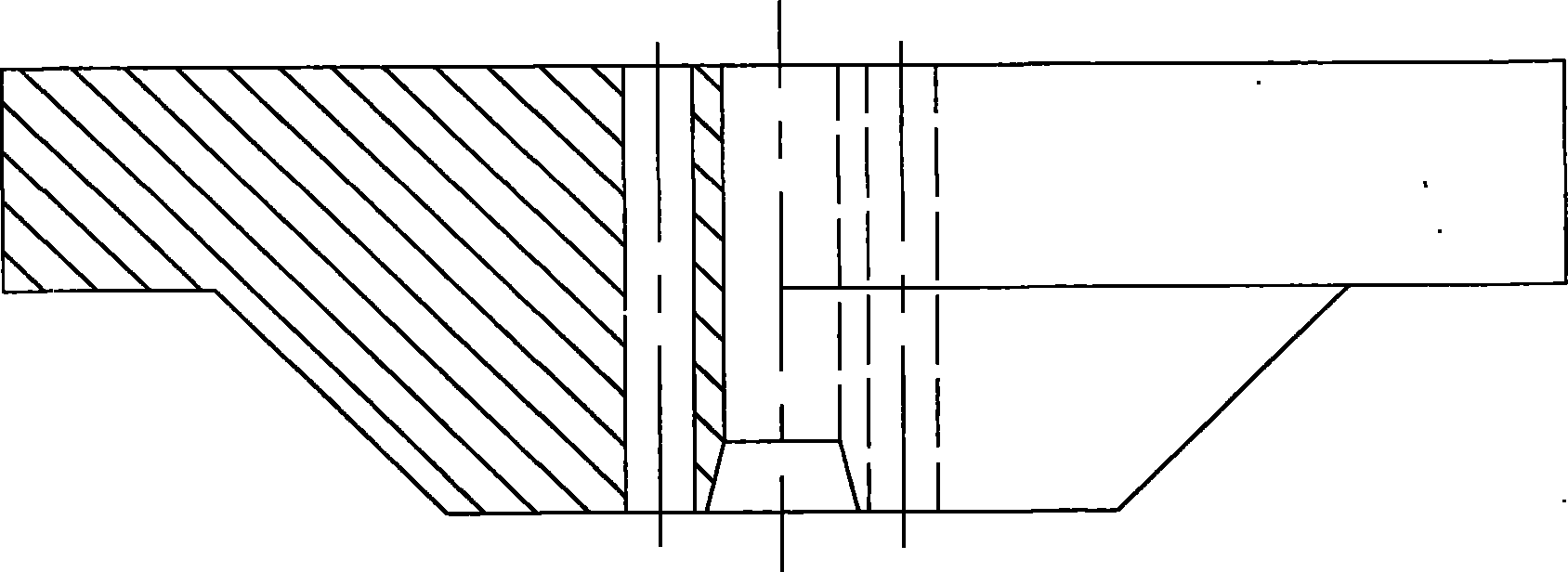

[0020] The invention relates to a measuring device and method for material melting volume expansion rate / melting state density. The device as figure 1 , figure 2 As shown, the sample 101 to be tested is placed in a cylindrical sample chamber 201 with a bottom and an opening. The sample chamber 201 is placed in the middle vertical blind hole heating chamber of the heating seat 301. There are 8 vertical blind holes with a diameter of 15mm evenly distributed on the circumference, and the depth of the holes is equal to the height of the sample chamber 201. Eight silicon carbide heating rods 302 with a diameter of 12mm are also at the same height as the sample chamber 201. Installed in the 8 blind holes on the heating base 301 , in order to facilitate the installation and replacement of the heating rods 302 , a detachable annular protection block 303 is embedded above the heating base 301 . A top cover 304 is placed above the protection block 303 . The heating seat 301, the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com