Device for testing heat sensitivity of material in enclosed space

A test device and closed space technology, applied in the field of thermally sensitive test devices, can solve the problem of no commercialized test device, etc., and achieve the effects of being easy to carry and move, preventing uneven stress on materials, and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

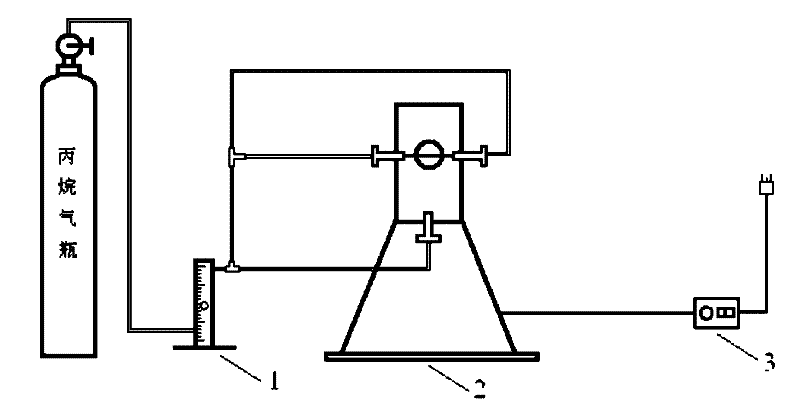

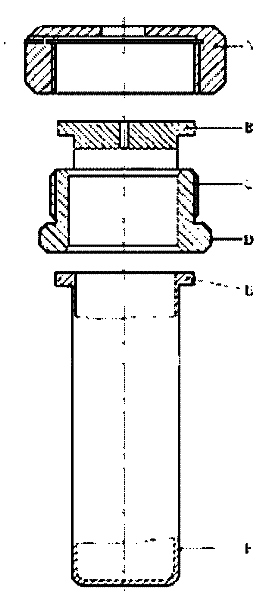

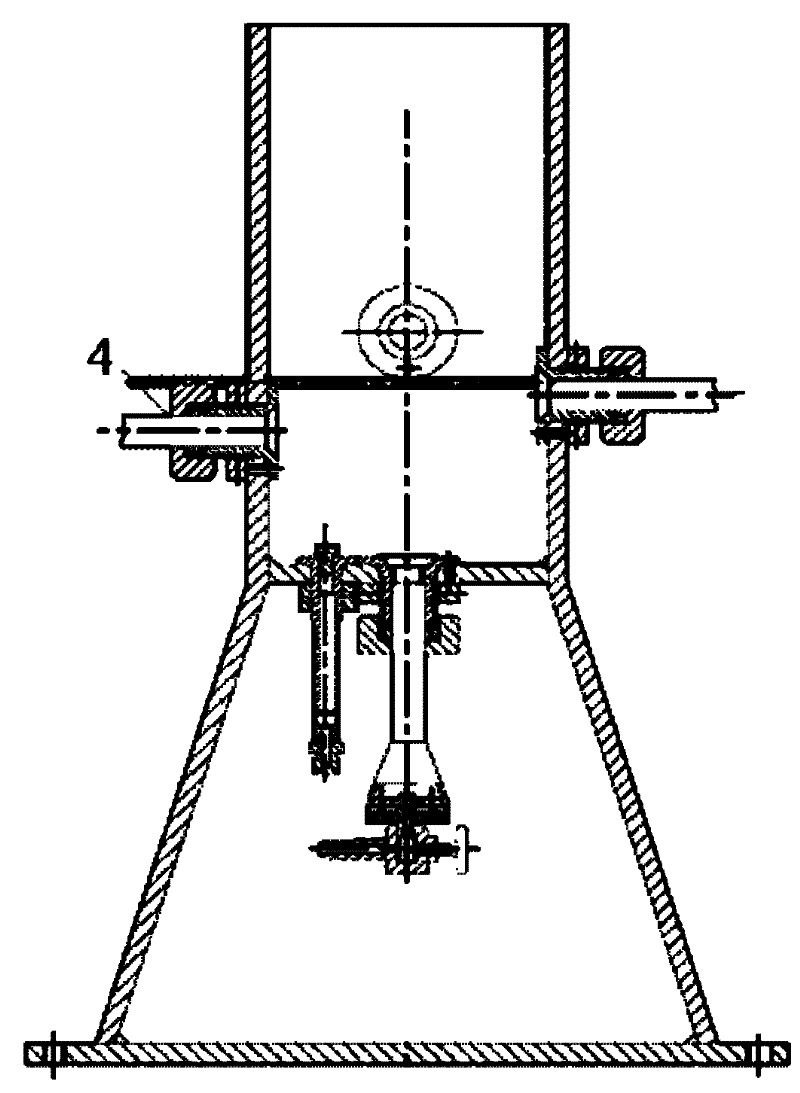

[0024] Such as figure 1 As shown, a test device for thermal sensitivity of a substance in a closed space includes a heating and protection device 2, a steel pipe and its closing device, a control switch 3, a gas source and a gas flow meter 1, a solid compacting device, a calibration laboratory balance, a steel Ruler, electronic stopwatch and other eight parts.

[0025] The heating and protection device 2 is used to heat the sample and protect the experimenter from the possible explosion of the steel pipe; the steel pipe and its closing device are used to seal the sample; the control switch 3 is used to open and close the electric spark and control the discharge of the gas; the gas fire The source is used for heating; the gas flow meter 1 is used to adjust the gas flow to achieve the corresponding heating rate; the solid compacting device is used to compact the solid material in the steel pipe; the calibration balance is used to weigh the quality of the solid material; the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com