Heating load forecast engineering method with crossed time sequence

A time series, engineering technology, applied in forecasting, instrumentation, data processing applications, etc., can solve the problems of complex calculation, low precision, slow speed, etc., to achieve high precision, fast forecast speed, and reduce the squared error effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

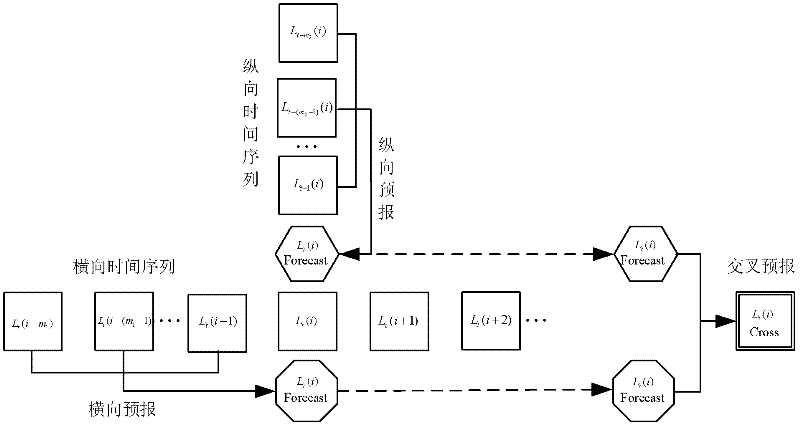

[0016] Specific implementation mode one: as figure 1 As shown, a time-series cross heating load forecasting engineering method described in this embodiment is implemented according to the following steps:

[0017] Step 1. Horizontal forecast: record the load at the i-th moment on the t-th day as L t (i), according to the lateral load time series, L t (i) From the previous m at the i-th moment 1 historical load forecast at a moment;

[0018] Step 2. Longitudinal forecast: record the load at time i on day t as L t (i), according to the longitudinal loading time series, L t (i) Available from m before the tth day 2 The historical load at the i-th moment of the day is used to forecast;

[0019] Step 3. Time series cross-forecast: On the basis of horizontal forecast and longitudinal forecast, combine the two forecasts, and determine the weighting coefficient of cross-forecast according to the principle of least square error sum, and obtain the cross-forecast model:

[0020] ...

specific Embodiment approach 2

[0022] Specific implementation mode two: the horizontal forecast and the vertical forecast described in this implementation mode are all realized by the AR model, and the AR model is determined by using the modeling theory of the Yule-Walker method and the F-order criterion, and the specific process is as follows:

[0023] Step A, description of AR model:

[0024] The AR model is an autoregressive model, and the system function H(z) of the AR model is expressed as

[0025] H ( z ) = G 1 + Σ i = 1 p a i z - i - - - ( 2 ...

specific Embodiment approach 3

[0055] Specific implementation manner three: In step three of this implementation manner, the weighting coefficients of the cross prediction are determined by the least square method. Other steps are the same as in the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap