Industrial process data-based method of alarm limit self-learning system based on

A technology for learning systems and industrial processes, applied in data processing applications, predictions, calculations, etc., to achieve the effect of improving stability and reducing time load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

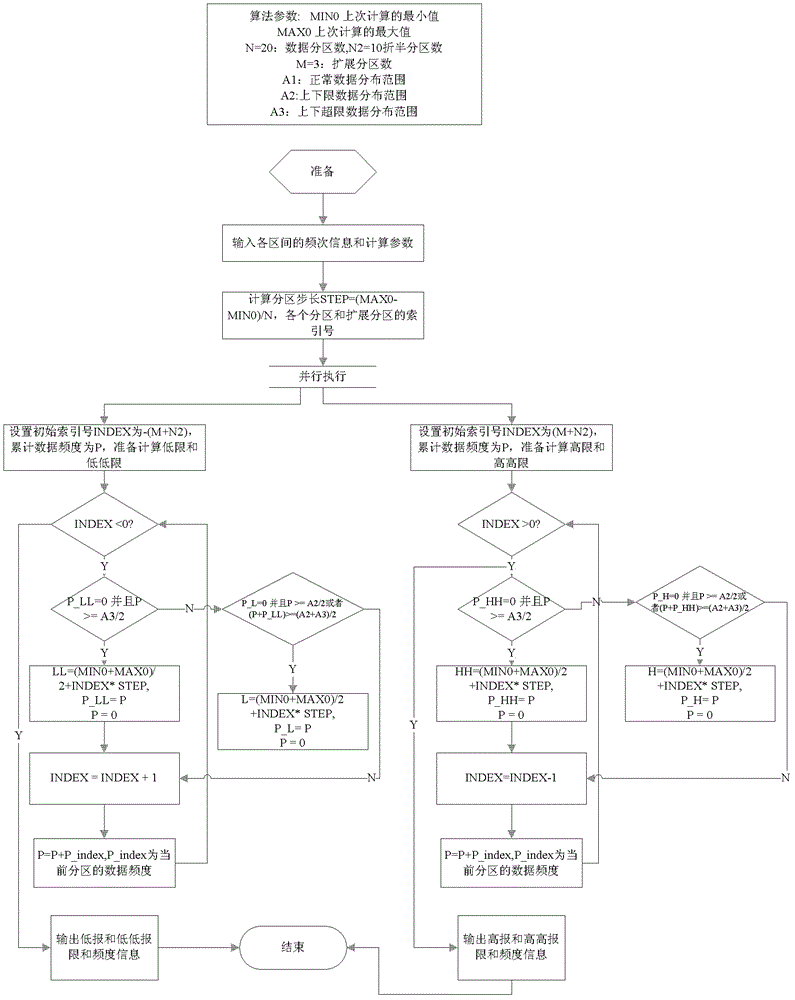

Method used

Image

Examples

Embodiment Construction

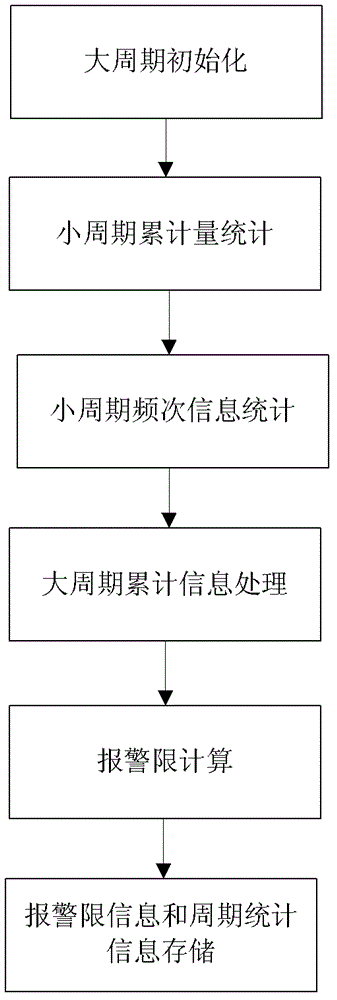

[0055] Provide the concrete implementation method of the present invention below. The input data for alarm limit calculation generally comes from real-time data on the industrial site, data once every 5 seconds or once every 10 seconds is enough, and data with too high frequency is not required. Under normal circumstances, the calculation of the small period is performed once an hour, and the calculation of the large period is performed once a month.

[0056] In the initialization phase, the values of the following calculation parameters need to be initialized:

[0057] Data sampling frequency: default 5-10 seconds

[0058] Number of data partitions: 20 by default

[0059] Number of extended partitions: default 3 (extend three intervals at the top and bottom)

[0060] Upper and lower overrun alarm interval data threshold: default 0.25%

[0061] Upper and lower limit alarm interval data threshold: default 5%

[0062] Normal data interval (from low limit to high limit) da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com