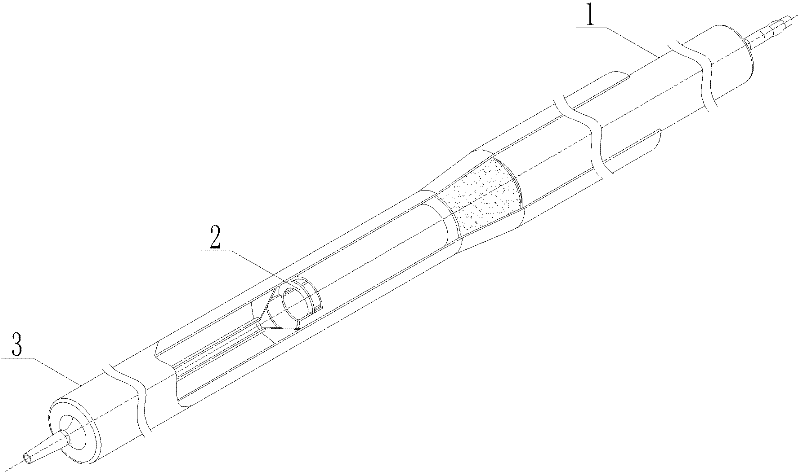

Quartz reactor of horizontal fixed bed

A fixed bed and reactor technology, which is applied in the field of horizontal fixed bed quartz reactors, can solve the problems of long delay time, large experimental error, slow gas flow rate, etc., and achieve the effect of reducing experimental error, reducing delay, and increasing the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

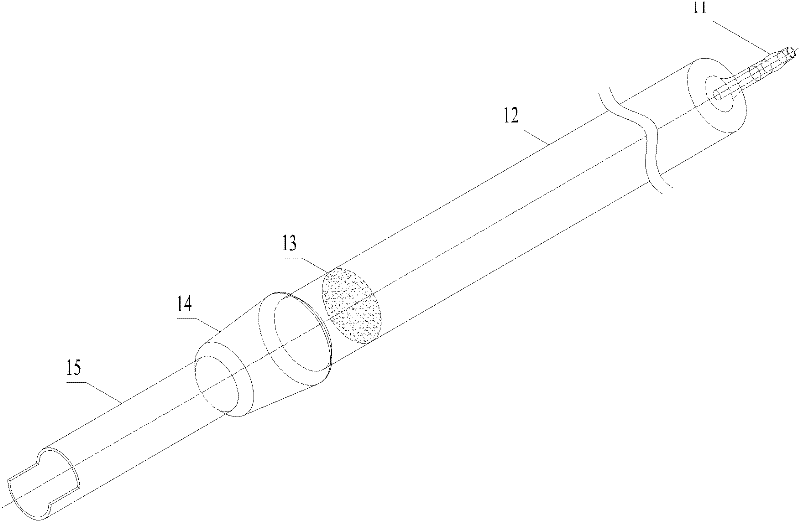

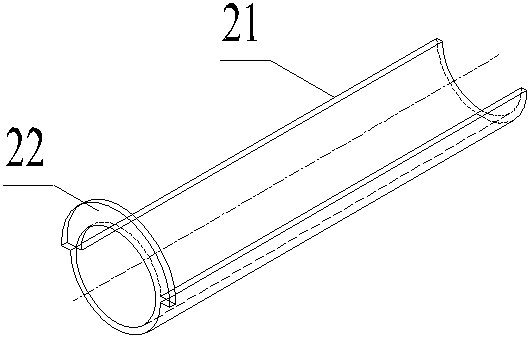

[0022] According to the requirements of the experimental conditions, the diameter and length of the carrier gas preheating section 12, the reaction section 15 and the exhaust pipe 35 can be adjusted, and the corresponding casing parameters can also be adjusted accordingly. The diameter of the carrier gas preheating section 12 is 45-60 mm, 50 mm is recommended, and the corresponding length is 400-500, 500 is recommended. The axial position of the air distribution plate 13 in the carrier gas preheating section 12 is adjustable, and it is recommended to be close to the end of the carrier gas preheating section. The diameter of the reaction section 15 is recommended to be 5-10mm smaller than the diameter of the carrier gas preheating section. The diameter of the sample loading platform 2 is 1-5 mm smaller than that of the reaction section 15, preferably 2 mm. The diameter of the exhaust pipe 35 is 3-6 mm, a higher value is recommended for low temperature conditions, and a lower v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap