Guard strip plate locking device

A locking device, technology of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

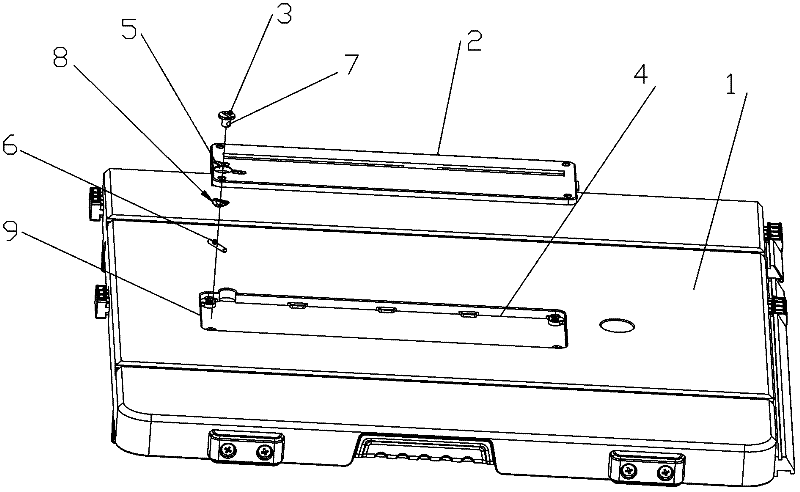

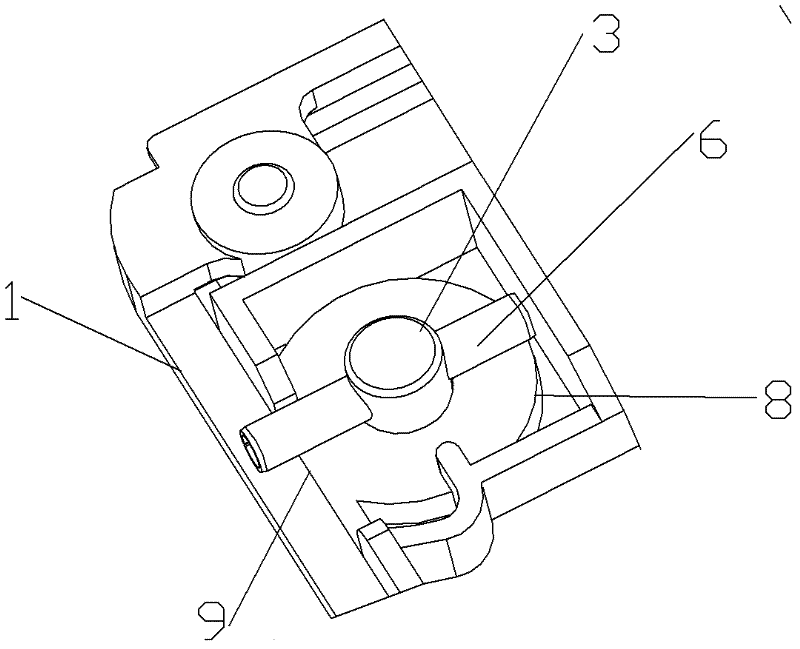

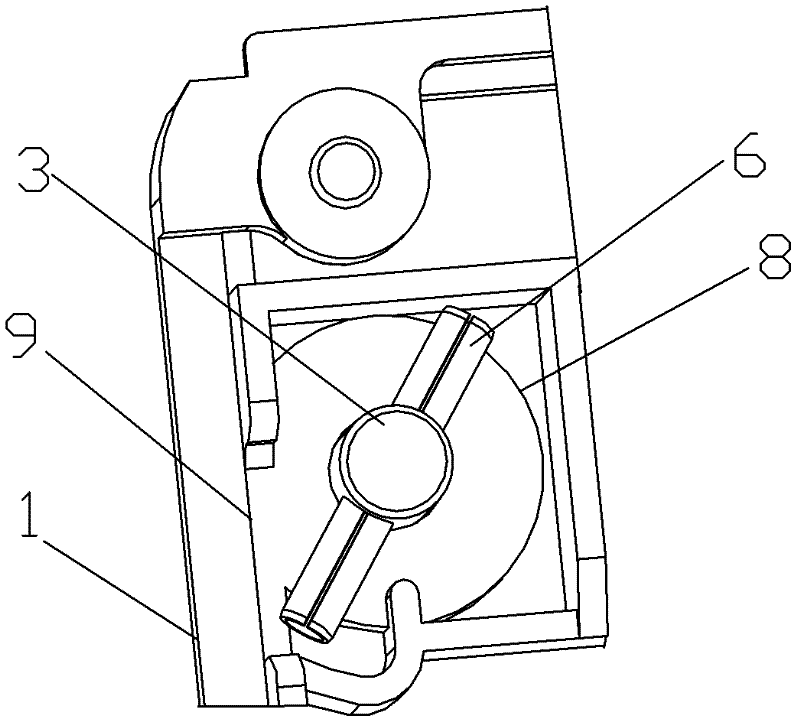

[0014] Such as Figure 1 to Figure 3 As shown, a kind of guard strip locking device of the present invention comprises workbench 1, guard strip 2 and locking screw 3, and guard strip 2 is placed in the groove 4 of workbench 1, and each guard strip 2 A round hole 5 is provided at the top corner, and the locking screw 3 passes through the round hole 5 and extends into the bottom of the workbench 1. The end of the locking screw 3 is provided with a through hole 7 for inserting the elastic pin 6; in the locked state, the elastic pin 6 is inserted into the through hole 7 and one end of the elastic pin 6 exceeds the edge 9 of the groove 4 of the workbench 1 so that the guard strip 2 is clamped on the workbench 1 . Usually, a wave washer 8 is provided on the locking screw 3 , and the wave washer 8 is located between the guard strip 2 and the elastic pin 6 .

[0015] During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com