Slideway for replacing conveying flat plate

A flatbed and slideway technology, applied in printing, printing devices, etc., can solve the problems of bulky printing flatbed, installation, commissioning, inconvenient transportation, large flatbed, etc., and achieve high cost performance, easy installation, and simple equipment as a whole Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

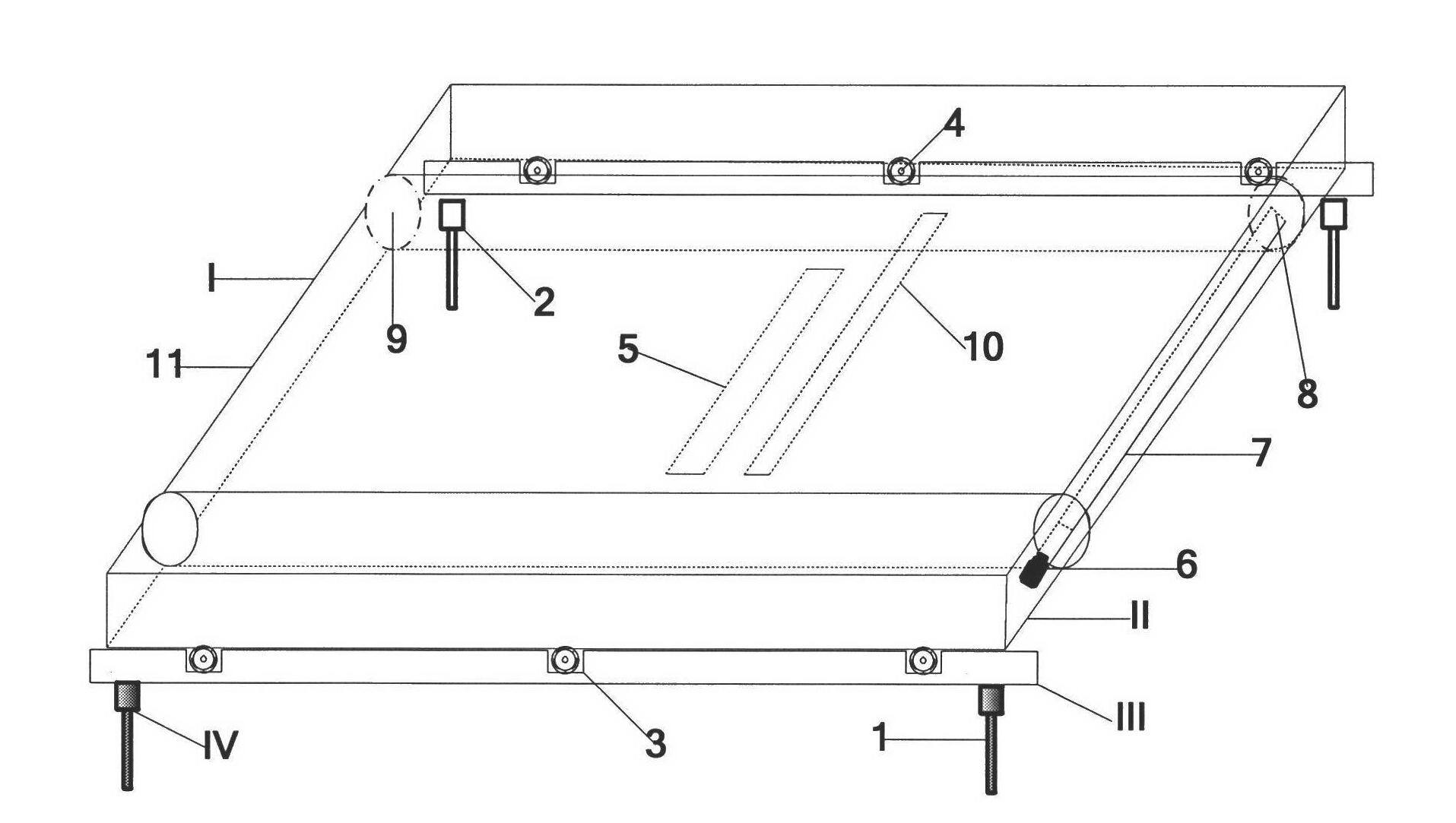

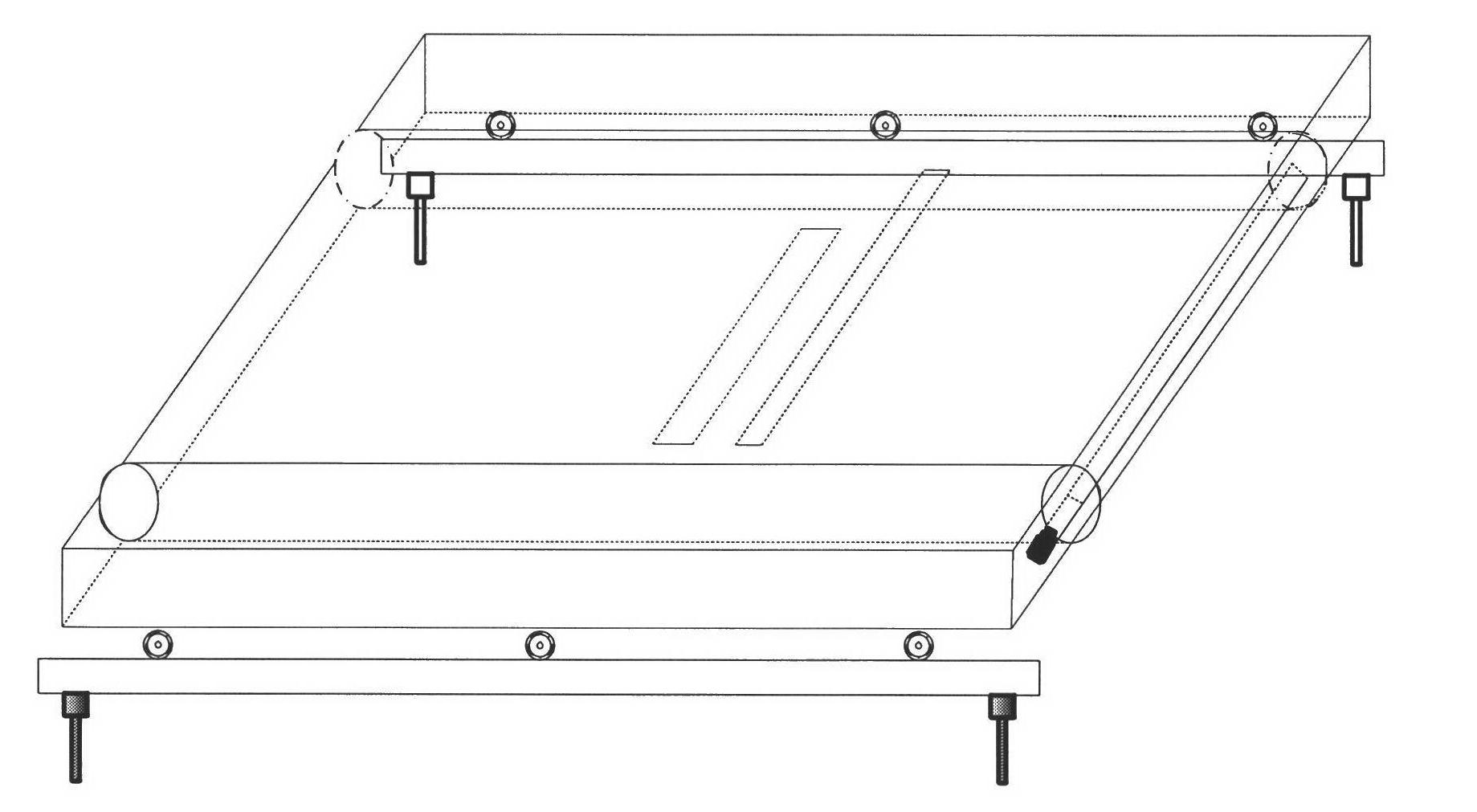

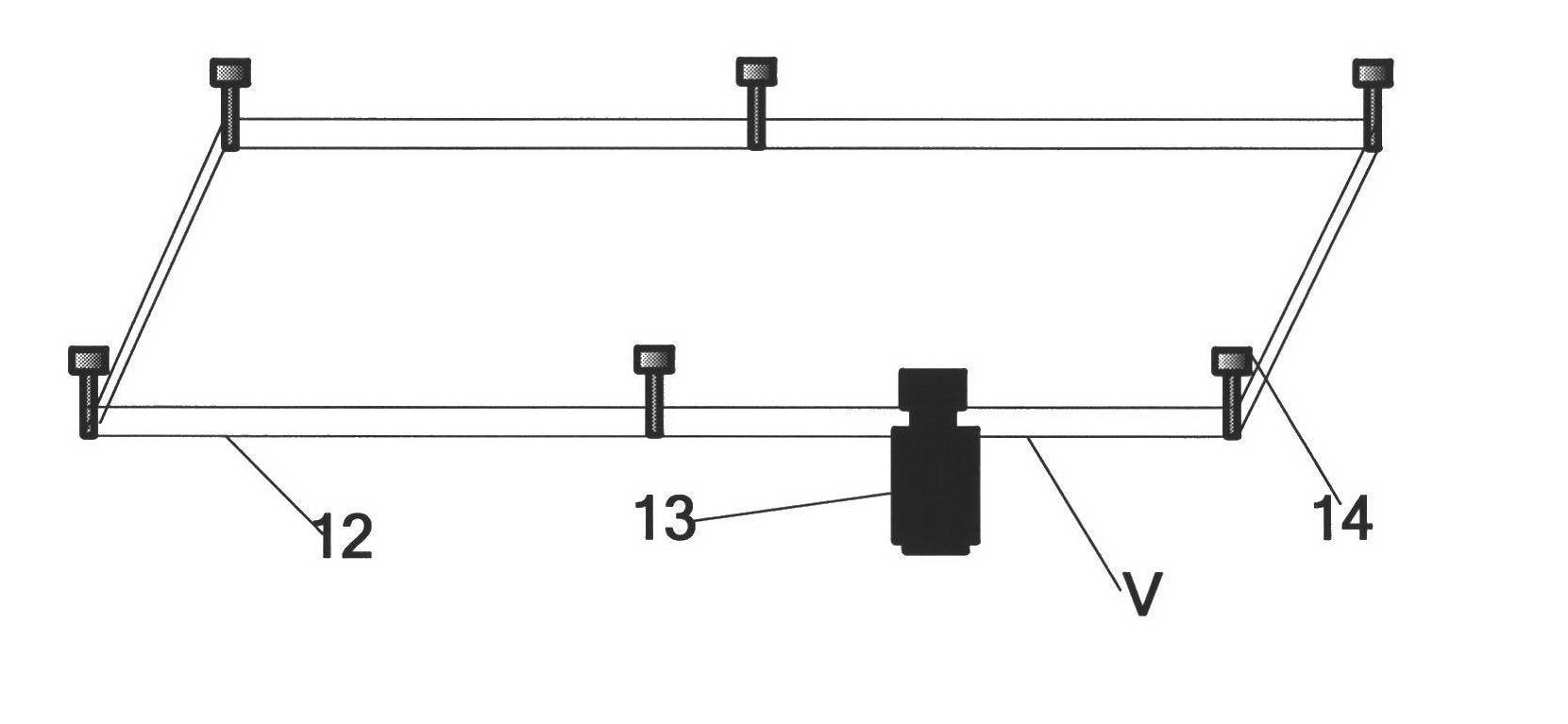

[0024] see figure 1 , image 3 , Figure 4 , the present invention mainly consists of a medium conveying plate (I), a fixing device (II), a replacement slideway (III), a height-adjustable support rod (IV), a control system (V) for a free landing seat in a groove, and a machine head Component (VI) is composed. Among them, see figure 1 , the left and right sides of the medium transmission plate (1) are arc-shaped, and the front and rear sides respectively have two driving wheels: the active driving wheel (8) and the passive driving wheel (9), and the heating device ( 5), the belt (11) with a large friction coefficient is wrapped on the outside of the flat plate, and the driving drive wheel (8) is driven by the motor (6) through the connecting rod (7), thereby driving the belt (11) wrapped on the outside to rotate, and the belt rotates Drive the printing medium attached to it to move.

[0025] Fixing devices (II) can be installed on both sides of the medium conveying plate (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com