Automatic detection device based on machine vision for defects of instant noodle sauce packets and method

An automatic detection device and instant noodle technology, applied in the directions of packaging automatic control, packaging, packaging protection, etc., can solve the problems of visual fatigue, high work intensity of workers, and no packaging, so as to overcome the interference of subjective factors and improve detection accuracy and efficiency. , the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

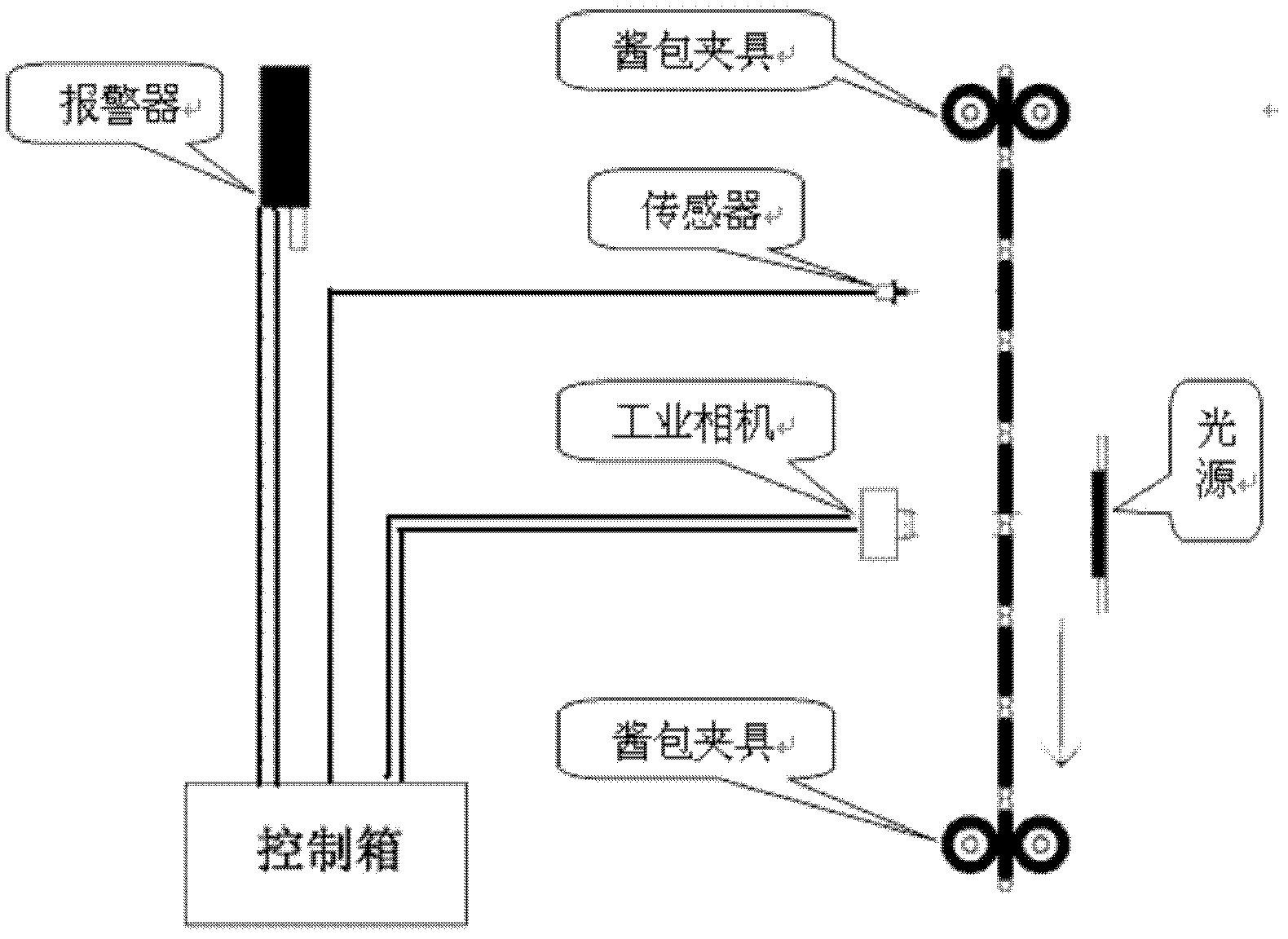

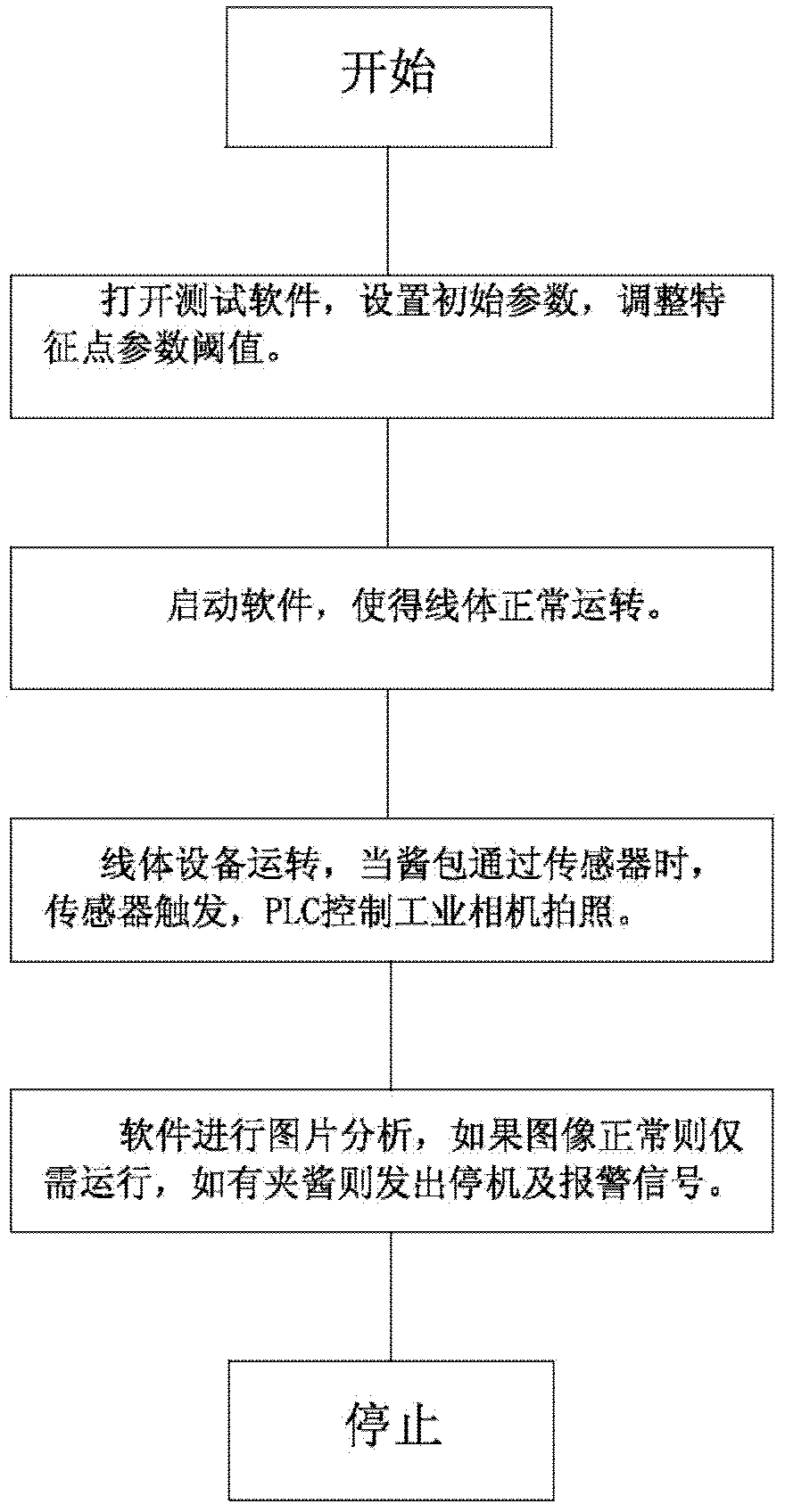

[0025] This embodiment is suitable for synchronously tracking the production and packaging of sauce packets, see figure 1 , in-position sensor 4 is a kind of photoelectric sensor, is installed on the sauce pack motion transmission bracket, and the signal of its synchronous output is sent to the PLC controller in the control box 1, mainly comprises PLC controller, image acquisition card and Industrial computer (computer); because the color of sauce bag is dark brown, in order to take pictures clearly, light source 6 of the present invention adopts LED red area array light source, and industrial camera 5 is installed in packing below the conveying roller, and sauce bag passes through roller type After the sauce bag fixture 3, pass through the camera mechanism, the camera mechanism is that the industrial camera 5 is relatively installed with the LED light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com