Method of knitting pile loops on common manual flat knitting machine

A terry and flat knitting technology, used in weft knitting, knitting, textiles and papermaking, etc., can solve problems such as knitting difficulties, and achieve the effects of enriching the variety of colors, simple and easy operation methods, and uniform size and structure of terry loops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The weaving of ordinary terry fabrics,

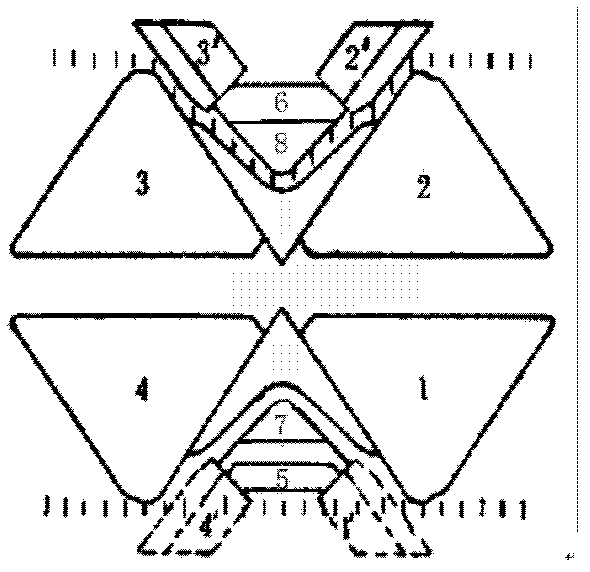

[0036] The double needle bed flat knitting machine is adopted, and the needle grooves of the two needle beds are adjusted to be alternately arranged, and the knitting needles are arranged on both needle beds.

[0037] Adjust the cams of the machine head so that all the cams of the rear machine head enter the working position, and all the cams of the front machine head withdraw from the working position, and push the machine head to knit, so that the knitting needles of the rear machine head are under the action of the cams of the rear machine head. Can start knitting normally; all the knitting needles on the front needle bed cannot start knitting.

[0038] When knitting in the next course, readjust the cams of the machine head so that the needle-lifting cams of the rear machine head quit working, and the other cams enter into work; all the cams of the front machine head enter into work. When the machine head is pushed for knitti...

Embodiment 2

[0041] Weaving of checkered jacquard terry fabric,

[0042] The pattern image of the jacquard terry fabric is as follows Figure 7 , a complete organization has 12 longitudinal rows and 12 horizontal columns. The needle grooves of the two needle beds are adjusted to be alternately arranged, and the two needle beds are all full of needles and arranged with knitting needles.

[0043] When knitting in the first row, push all the knitting needles of the rear needle bed to the working position, and push every 6 knitting needles of the front needle bed to the working position. Adjust the cams of the machine head so that all the cams of the rear machine head enter the working position, and all the cams of the front machine head withdraw from the working position, and push the machine head to knit, so that the knitting needles of the rear needle bed are under the action of the cams of the rear machine head. Can start knitting normally; all the knitting needles on the front needle be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com