Electromagnetic tamper

A tamping machine and electromagnetic technology, applied in the direction of electromagnet, soil protection, construction, etc., can solve the problems of uneven force on the ground, increased energy consumption, small impact, etc., and achieve adjustable and reduced impact frequency and vibration amplitude Energy draining, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

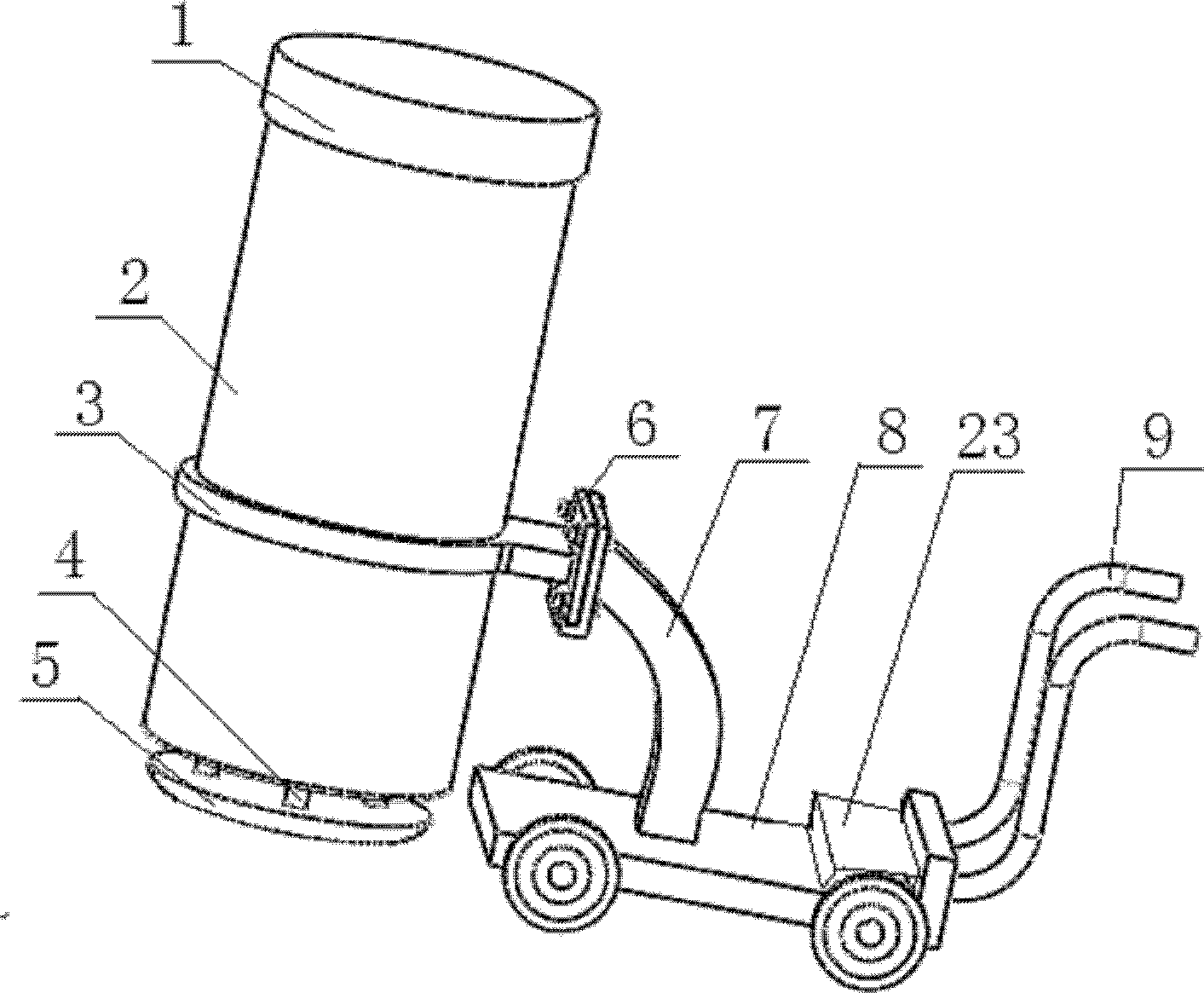

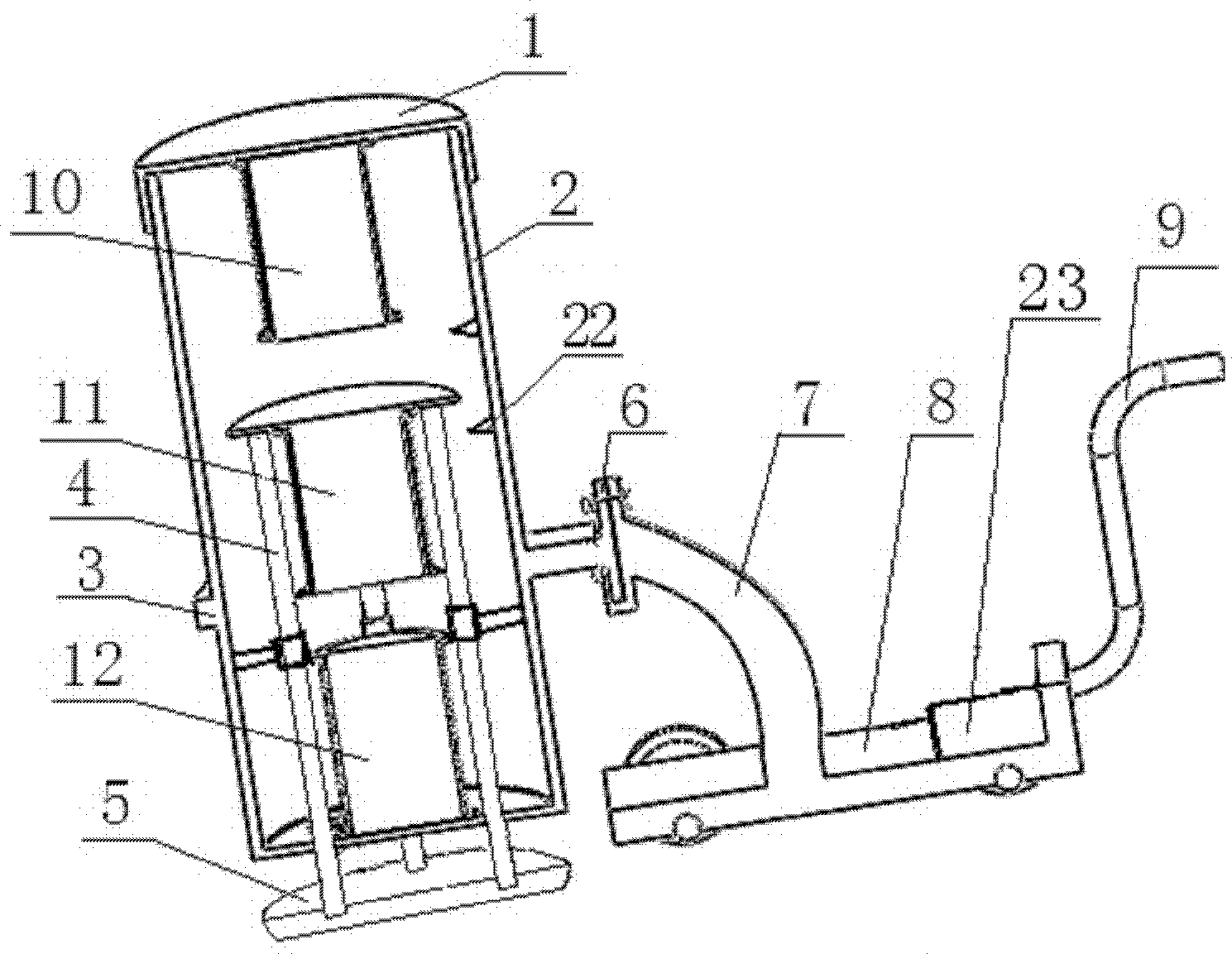

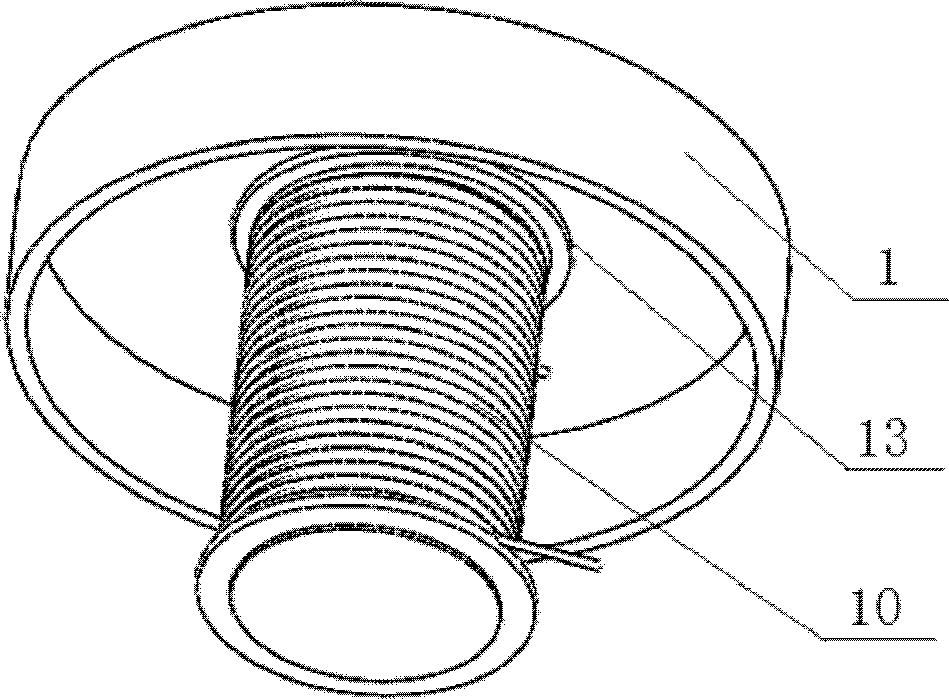

[0024] Embodiment 1: The structure of a kind of electromagnetic tamping machine of the present invention is as follows figure 1 , 2 As shown, it includes a casing, a pressure plate body, an electromagnet, a travel switch and a trolley. The casing is composed of a top cover 1 and a casing cylinder 2. The lower end of the casing casing is provided with a circular groove bottom; the inner wall of the casing casing Guide holes 14 are provided; the platen body is composed of a middle plate 17, a pressure head 5 and four pressure rods 4, and the four pressure rods 4 are connected to the middle plate 17 and the pressure head 5, and the pressure head is at the lowermost end of the pressure plate body ; The electromagnets described see figure 2 Consists of top electromagnet 10, middle electromagnet 11 and bottom electromagnet 12; top part assembly of the present invention sees image 3 , the top electromagnet is welded on the top annular groove 13 of the top cover 1; the bottom elec...

Embodiment 2

[0026] Embodiment 2: the assembly process of a kind of electromagnetic compactor of the present invention is:

[0027] (1) Electromagnet assembly: Assemble two electromagnets with a sleeve, iron core and coil, first wind the coil on the sleeve, and then insert the iron core into the sleeve with the coil, and the iron core and the sleeve have an interference fit , for the top electromagnet and the bottom electromagnet; then use a sleeve to wind the coil of the middle electromagnet, and the iron core is loaded into the sleeve of the middle electromagnet through interference fit; the bottom of the middle electromagnet is fixed on the tray with four bolts superior.

[0028](2) Assembling the housing cylinder: First, use an assembled bottom electromagnet to connect the circular bottom groove at the bottom of the housing cylinder by welding; then assemble the assembled middle electromagnet into the housing cylinder, and four pressing rods Connect along the four fixed guide holes 14...

Embodiment 3

[0034] Embodiment 3: The working process of the electromagnetic tamping machine of the present invention is: when the controller is not powered, the middle electromagnet is in the lower part of the casing due to gravity, and is in contact with the lower travel switch at this time. When the controller is powered on, the top electromagnet The upper part of the top electromagnet is S pole, and the lower part is N pole; the upper part of the bottom electromagnet is N pole, and the lower part is S pole; according to the signal from the travel switch, the controller will set the middle electromagnetic The iron supplies power, so that the upper part of the middle electromagnet is an S pole, and the lower part is an N pole. In this way, the top electromagnet will give the middle electromagnet a suction force, and the bottom electromagnet will give the middle electromagnet a repulsion force, prompting the middle electromagnet to go back. The current to the middle electromagnet is small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com