Wheel cylinder for automobile

A technology for wheel cylinders and automobiles, which is applied to gear transmission mechanisms, brake actuators, mechanical equipment, etc. It can solve problems such as jamming, oil leakage, poor sealing performance and dustproof performance, etc., so as to ensure sealing performance and guarantee Effect of Dustproof Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

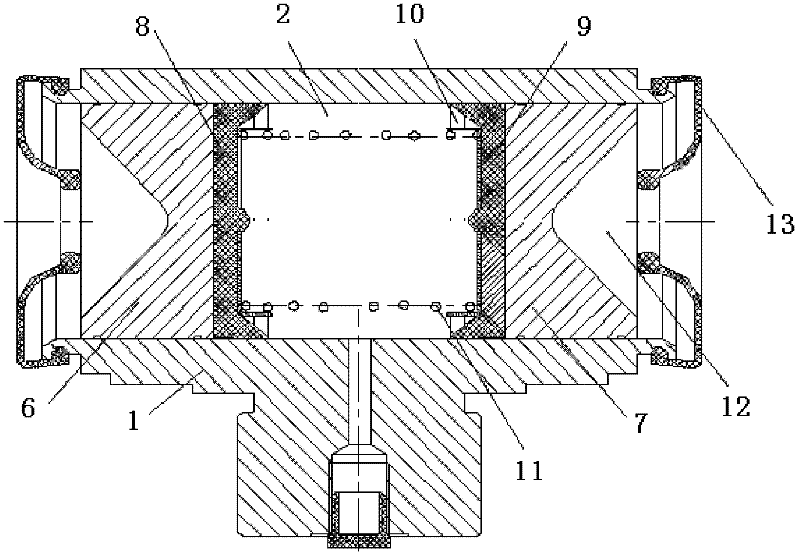

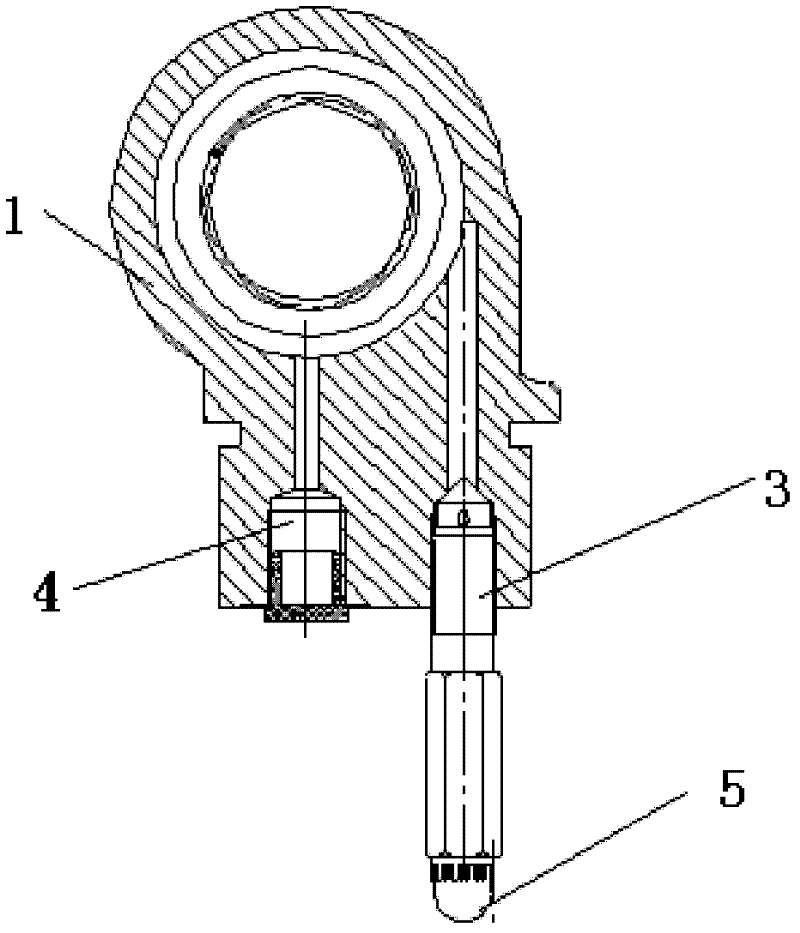

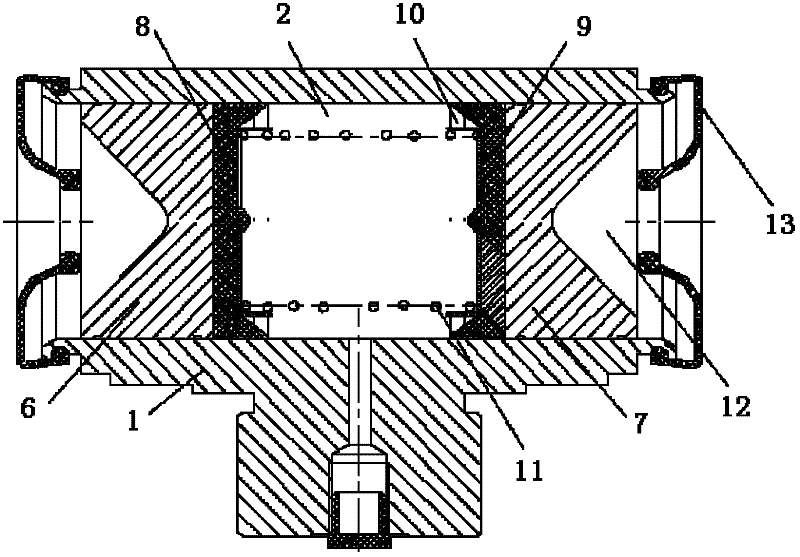

[0012] Referring to the accompanying drawings, an automobile wheel cylinder includes a cylinder body 1, a cavity 2 is provided in the cylinder body 1, and an air release screw 3 and an oil inlet 4 are communicated on the side wall of the cavity body 2. The top of the air screw 3 is provided with a deflation cap 5, and the left and right ends of the cavity 2 are respectively slidably mounted with left and right pistons 6, 7, and left and right pistons 6, 7 are provided with left and right skins on adjacent surfaces. Bowls 8, 9, the leather cups 8, 9 are fixedly installed on the side walls of the left and right pistons 6, 7 respectively, the leather cups 8, 9 are closely attached to the side walls of the cavity 2, and the left and right leather bowls Spring seats 10 are fixedly installed on the end faces of 8 and 9, and springs 11 are clamped between the two spring seats 10. The outer end faces of the left and right pistons 6, 7 have concave cavities 12, and the cylinder body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com