Dust cover for front swing arm of minibus

A technology of minibus and dust cover, which is applied to the sealing of engines, engine components, mechanical equipment, etc. It can solve the problems of weak fastening force, weakened dust-proof effect, and many assembly processes, so as to prevent foreign objects and dust Ingress, protection against dust and water, and improvement of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

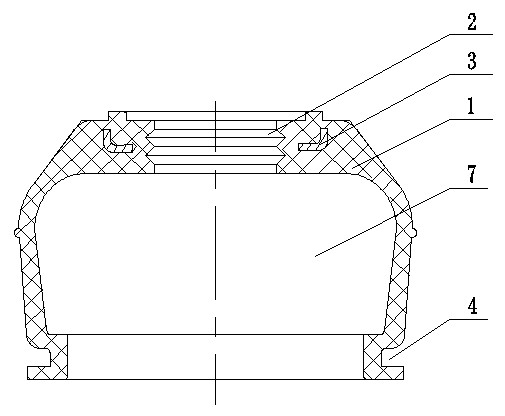

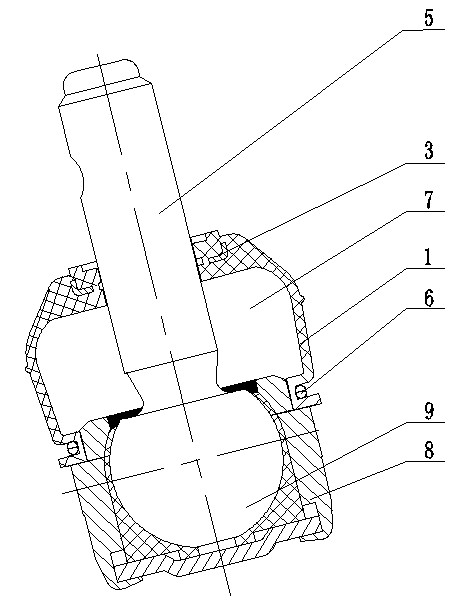

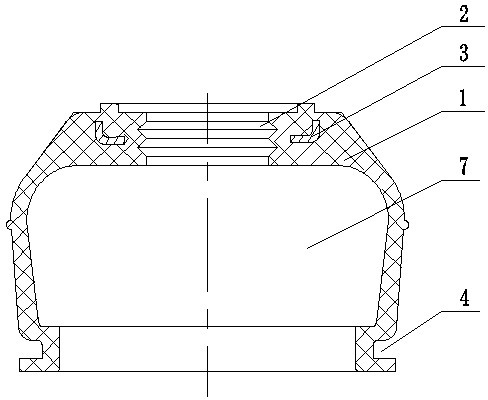

[0012] Such as figure 1 As shown, the present invention has a dust cover main body 1, the dust cover main body 1 is molded by injection molding, and has an accommodating cavity 7, the lower end of the accommodating cavity 7 is open, and a slightly smaller diameter is provided at the opening. Reduced diameter section. An annular groove 4 is formed on the outer wall of the lower end of the dust cover main body 1 for installing an outer hoop. The upper end of the dust cover main body 1 is provided with a sealing port 2, the sealing port 2 is located above the accommodating cavity 7, and the lower port of the sealing port 2 communicates with the accommodating cavity 7 of the dust cover main body 1, and the sealing port 2 The upper port of the upper port penetrates the top surface of the dust cover main body 1 . At least one "V"-shaped ring groove is formed on the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com